Method for improving efficiency of producing methane by reinforced anaerobic digestion of hydrochar

A technology of anaerobic digestion and hydrothermal charcoal, which is applied in the field of resource utilization of organic waste, can solve the problems of no research on hydrothermal charcoal, and achieve the effect of reduction and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Add 300 g of corn stalk powder and 2 L of water into a 3 L high-temperature and high-pressure reactor, react at 260 °C for 1 hour to prepare hydrothermal charcoal, wash off the soluble organic matter on the surface of hydrothermal charcoal with alcohol and dry it ;

[0019] (2) Put the dried hydrothermal charcoal into a planetary ball mill for 8 hours at a speed of 300 rpm.

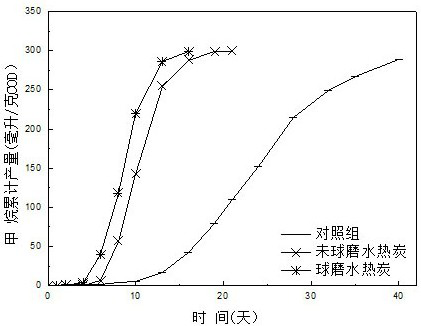

[0020] (3) Set up three sets of anaerobic reactors, each with a volume of 108 mL, filled with 60 mL of glucose solution with a concentration of 4 g / L, inoculated with the same amount of microorganisms (F / M=2), and adjusted the reaction The initial pH in the vessel was 7.5, no hydrothermal charcoal was added, 10 g / L unmilled hydrothermal charcoal was added, and 10 g / L ball milled hydrothermal charcoal was added. After nitrogen was blown off to create an anaerobic environment, the three groups of reaction The device was placed in a reactor at 37°C for anaerobic fermentation. During the fermentat...

Embodiment 2

[0023] (1) Add 300 g of corn stalk powder and 2 L of water into a 3 L high-temperature and high-pressure reactor, react at 260 °C for 8 hours to prepare hydrothermal charcoal, wash off the soluble organic matter on the surface of hydrothermal charcoal with alcohol and dry it ;

[0024] (2) Put the dried hydrothermal charcoal into a planetary ball mill for 8 hours at a speed of 300 rpm.

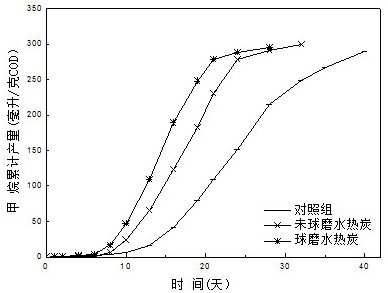

[0025] (3) Set up three sets of anaerobic reactors, each with a volume of 108 mL, filled with 60 mL of glucose solution with a concentration of 4 g / L, inoculated with the same amount of microorganisms (F / M=2), and adjusted the reaction The initial pH in the vessel was 7.5, no hydrothermal charcoal was added, 10 g / L unmilled hydrothermal charcoal was added, and 10 g / L ball milled hydrothermal charcoal was added. After nitrogen was blown off to create an anaerobic environment, the three groups of reaction The device was placed in a reactor at 37°C for anaerobic fermentation. During the fermenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com