Production method of novel environment-friendly anode carbon block

A technology of anode carbon block and production method, applied in the field of carbon industry, can solve the problems affecting the operation stability of electrolyzers, increase the labor intensity of employees, poor working environment, etc., so as to reduce the labor intensity of employees, reduce the labor intensity of employees, and reduce the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

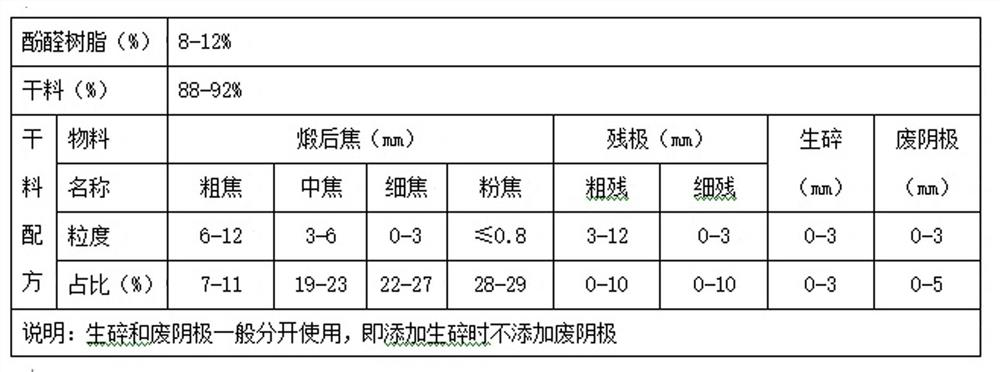

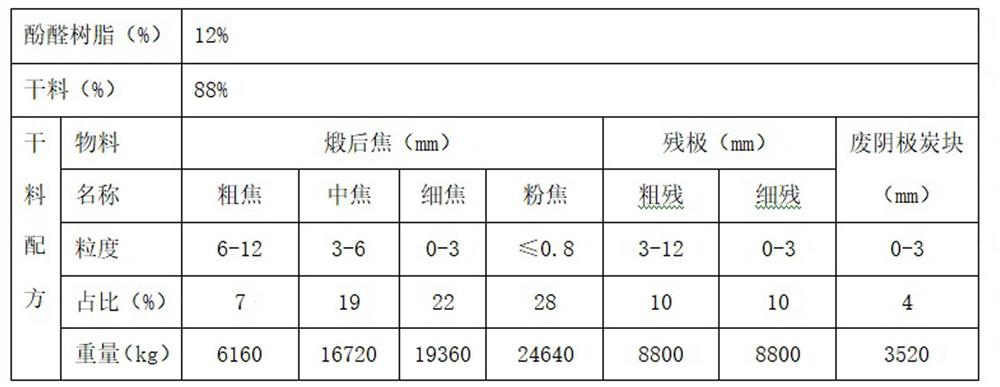

[0028] Embodiment 1, the total amount of material is 100000kg, according to the dry material accounted for 88%, lignin modified phenolic resin accounted for 12% formula, dry material includes calcined coke, residual pole and waste cathode carbon block; calcined coke medium particle size Coarse coke with a particle size of 6-12mm accounts for 7% of the total dry material weight, medium coke with a particle size of 3-6mm accounts for 19% of the total dry material weight, and fine coke with a particle size of 0-3mm accounts for 22% of the total dry material weight. Coke powder with particle size less than or equal to 0.8mm accounts for 28% of the total dry material weight; coarse residue with a particle size of 3-6mm accounts for 10% of the total dry material weight, and fine residue with a particle size of 0-3mm accounts for the total dry material weight 10% of 10%; spent cathode carbon blocks with a particle size of 0-3mm account for 4% of the total dry material weight, that is,...

Embodiment 2

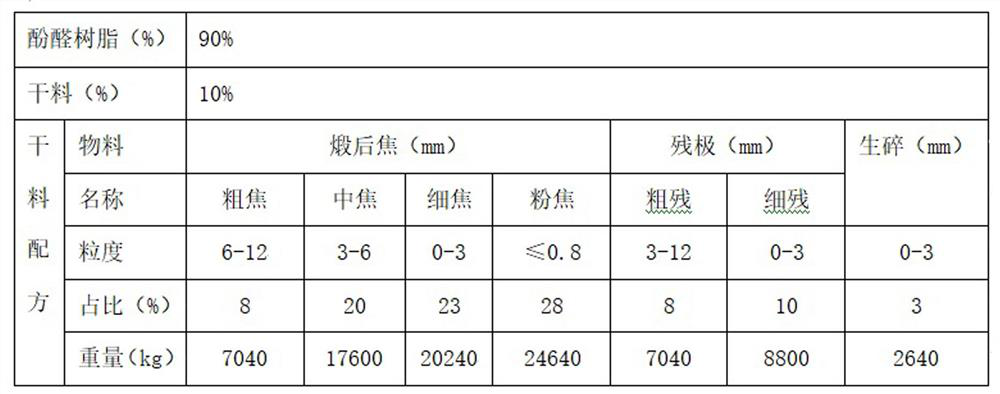

[0030]Embodiment 2. The total amount of material is 100000kg. According to the formula that dry material accounts for 90% and pitch modified phenolic resin accounts for 10%, dry material includes calcined coke, residual pole and raw crushed; the particle size of calcined coke is 6- 12mm coarse coke accounts for 8% of the total dry material weight, medium coke with a particle size of 3-6mm accounts for 20% of the total dry material weight, fine coke with a particle size of 0-3mm accounts for 23% of the total dry material weight, and the particle size is less than or equal to Powder coke with a particle size of 0.8mm accounts for 28% of the total dry material weight; the coarse residue with a particle size of 3-6mm accounts for 8% of the total dry material weight, and the fine residue with a particle size of 0-3mm accounts for 10% of the total dry material weight ;Raw coke with a particle size of 0-3mm accounts for 3% of the total dry material weight, that is, weigh 7040kg of coa...

Embodiment 3

[0032] Embodiment 3, the total amount of material is 100000kg, accounts for 92% according to dry material, cardanol modified phenolic resin accounts for 8% formula, and dry material comprises calcined coke, residual pole and waste cathode carbon block; The particle size in calcined coke is 6 Coarse coke with a particle size of -12mm accounts for 11% of the total dry material weight, medium coke with a particle size of 3-6mm accounts for 20% of the total dry material weight, and fine coke with a particle size of 0-3mm accounts for 22% of the total dry material weight. The powder coke equal to 0.8mm accounts for 28% of the total dry material weight; the coarse residue with a particle size of 3-6mm accounts for 7% of the total dry material weight, and the fine residue with a particle size of 0-3mm accounts for 7% of the total dry material weight. %; The spent cathode carbon block with a particle size of 0-3mm accounts for 5% of the total dry material weight, that is, weigh 9680kg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com