Treatment method for resource utilization of strong brine in coking enterprises

A treatment method and technology of concentrated brine, applied in water/sewage treatment, metallurgical wastewater treatment, chemical instruments and methods, etc., can solve the problems of direct discharge not meeting discharge standards, corrosion and scaling of equipment pipes and nozzles, concentration of concentrated brine pollutants High-level problems, to achieve stable treatment effect, improve recycling rate, and reduce membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

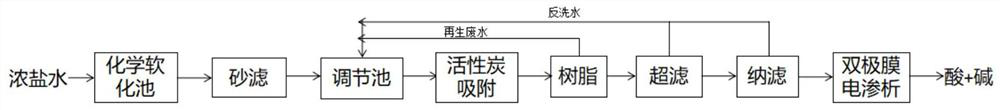

Image

Examples

Embodiment 1

[0024] A treatment method for resource utilization of concentrated brine in coking enterprises. The treatment object is the concentrated brine produced by membrane method in coking enterprises. Its conductivity is 9.0ms / cm, COD is 80mg / L, and total hardness is 1300mg / L.

[0025] 1. The concentrated brine of the coking enterprise first enters the chemical softening tank, adds 800mg / L calcium hydroxide and 400mg / L sodium carbonate, and stirs for 20 minutes to remove the scaling ions in the concentrated brine.

[0026] 2. The effluent enters the sand filter tank for filtration. The lower layer is filled with steel slag with a particle size of 1.2mm, and the upper layer is filled with quartz sand with a particle size of 0.5mm. The filter material uses both quartz sand and steel slag to retain solid particles and colloids of different particle sizes in the water.

[0027] 3. After filtration, the effluent enters the pH adjustment tank, adjusts the pH value to 7.0, and then enters th...

Embodiment 2

[0031] A treatment method for resource utilization of concentrated brine in coking enterprises. The treatment object is the concentrated brine produced by membrane method in coking enterprises. Its conductivity is 11.0ms / cm, COD is 100mg / L, and total hardness is 1400mg / L.

[0032] 1. The concentrated brine of the coking enterprise first enters the chemical softening pool, add 900mg / L calcium hydroxide and 450mg / L sodium carbonate, and stir for 25 minutes to remove the scaling ions in the concentrated brine.

[0033] 2. The effluent enters the sand filter tank for filtration. The lower layer is filled with steel slag with a particle size of 1.3mm, and the upper layer is filled with quartz sand with a particle size of 0.8mm. The filter material uses both quartz sand and steel slag to retain solid particles and colloids of different particle sizes in the water.

[0034] 3. After filtration, the effluent enters the pH adjustment tank, adjusts the pH value to 7.5, and then enters th...

Embodiment 3

[0038] A treatment method for resource utilization of concentrated brine in coking enterprises. The treatment object is the concentrated brine produced by membrane treatment in coking enterprises. Its conductivity is 12.0ms / cm, COD is 120mg / L, and total hardness is 1500mg / L.

[0039] 1. The concentrated brine of the coking enterprise first enters the chemical softening pool, add 1000mg / L calcium hydroxide and 500mg / L sodium carbonate, and stir for 30 minutes to remove the scaling ions in the concentrated brine.

[0040] 2. The effluent enters the sand filter tank for filtration. The lower layer is filled with steel slag with a particle size of 1.5mm, and the upper layer is filled with quartz sand with a particle size of 1.0mm. The filter material uses both quartz sand and steel slag to retain solid particles and colloids of different particle sizes in the water.

[0041] 3. After filtration, the effluent enters the pH adjustment tank, adjusts the pH value to 8.0, and then enter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com