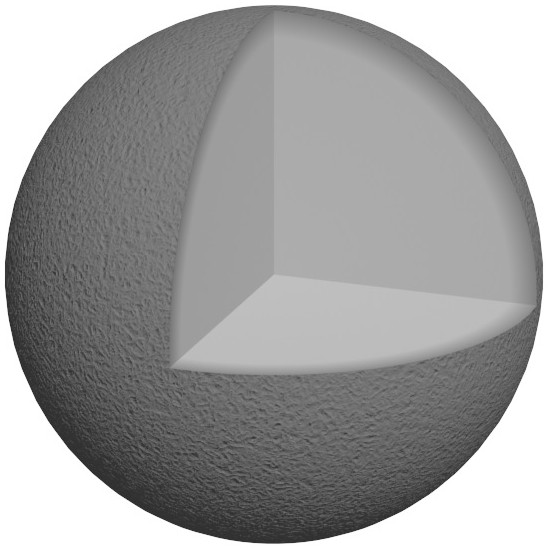

4.7 V-grade lithium cobalt oxide positive electrode material, preparation method thereof and corresponding battery

A positive electrode material, lithium cobalt oxide technology, applied in the field of 4.7V lithium cobalt oxide positive electrode material and its preparation, can solve the problem of low capacity of lithium cobalt oxide positive electrode material, achieve good cycle stability, simple preparation process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

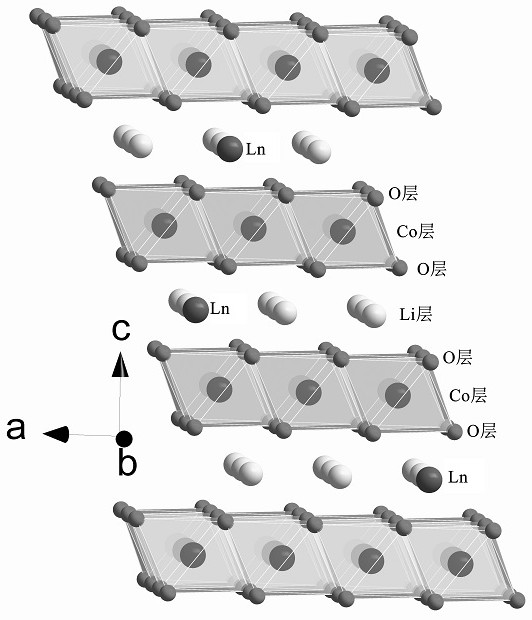

Method used

Image

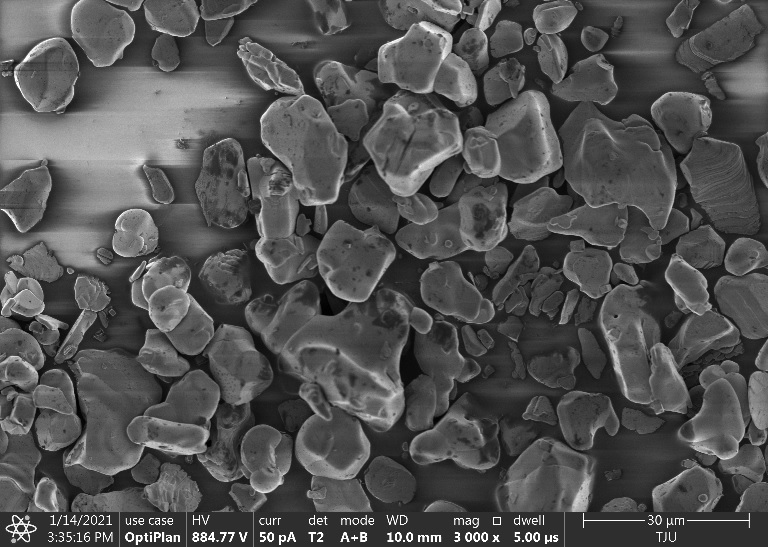

Examples

Embodiment 1

[0037] Take Co respectively 3 o 4 , Li 2 CO 3 and EuCl 3 ·6H 2 O is fed according to the molar ratio of Co, Li and Eu at 1:1.05:0.02, and the EuCl 3 ·6H 2 O was dissolved in distilled water, and then Co 3 o 4 , stirred at 80°C until all the water evaporated, and then mixed with Li 2 CO 3 Mix well and place in a muffle furnace for high-temperature sintering. The sintering process is as follows: raise the temperature to 1000°C at a rate of 5°C / min, keep it warm for 12 hours, and collect the sintered product after natural cooling; High-temperature sintering in the Fu furnace, the secondary sintering process is as follows: raise the temperature to 900°C at a rate of 5°C / min, keep the heat for 10 hours, collect the secondary sintering products after natural cooling; the final product is obtained after the secondary sintering products are crushed .

Embodiment 2

[0039] Take Co respectively 3 o 4 , Li 2 CO 3 and Gd(NO 3 ) 3 ·6H 2 O is fed at a molar ratio of Co, Li, and Gd of 1:1.05:0.02. Gd(NO 3 ) 3 ·6H 2 O was dissolved in distilled water, and then Co 3 o 4 , stirred at 80°C until all the water evaporated, and then mixed with Li 2 CO 3 Mix well and place in a muffle furnace for high-temperature sintering. The sintering process is as follows: raise the temperature to 1100°C at a rate of 5°C / min, keep it warm for 10 hours, and collect the sintered product after natural cooling; High-temperature sintering in a furnace, the secondary sintering process is as follows: raise the temperature to 1000°C at a rate of 5°C / min, keep the heat for 4 hours, collect the secondary sintering products after natural cooling; the final product is obtained after the secondary sintering products are crushed .

Embodiment 3

[0041] Take Co respectively 3 o 4 , Li 2 CO 3 and Ho 2 (SO 4 ) 3 ·8H 2 O is fed according to the Co, Li, Ho molar ratio of 1:1.05:0.02. Ho first 2 (SO 4 ) 3 ·8H 2 O was dissolved in distilled water, and then Co 3 o 4 , stirred at 80°C until all the water evaporated, and then mixed with Li 2 CO 3 Mix well and place in a muffle furnace for high-temperature sintering. The sintering process is as follows: raise the temperature to 1200°C at a rate of 5°C / min, keep it warm for 12 hours, and collect the sintered product after natural cooling; High-temperature sintering in a furnace, the secondary sintering process is as follows: raise the temperature to 1000°C at a rate of 5°C / min, keep the heat for 4 hours, collect the secondary sintering products after natural cooling; the final product is obtained after the secondary sintering products are crushed .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com