Robot-assisted large-scale fiber-reinforced heterogeneous multi-material in-situ additive manufacturing system

A robot-assisted and fiber-reinforced technology, which is applied in the direction of additive processing, manufacturing, and additive processing of mixtures of solid materials and liquid materials, can solve the problems of continuous carbon fiber and a variety of resin materials such as less occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

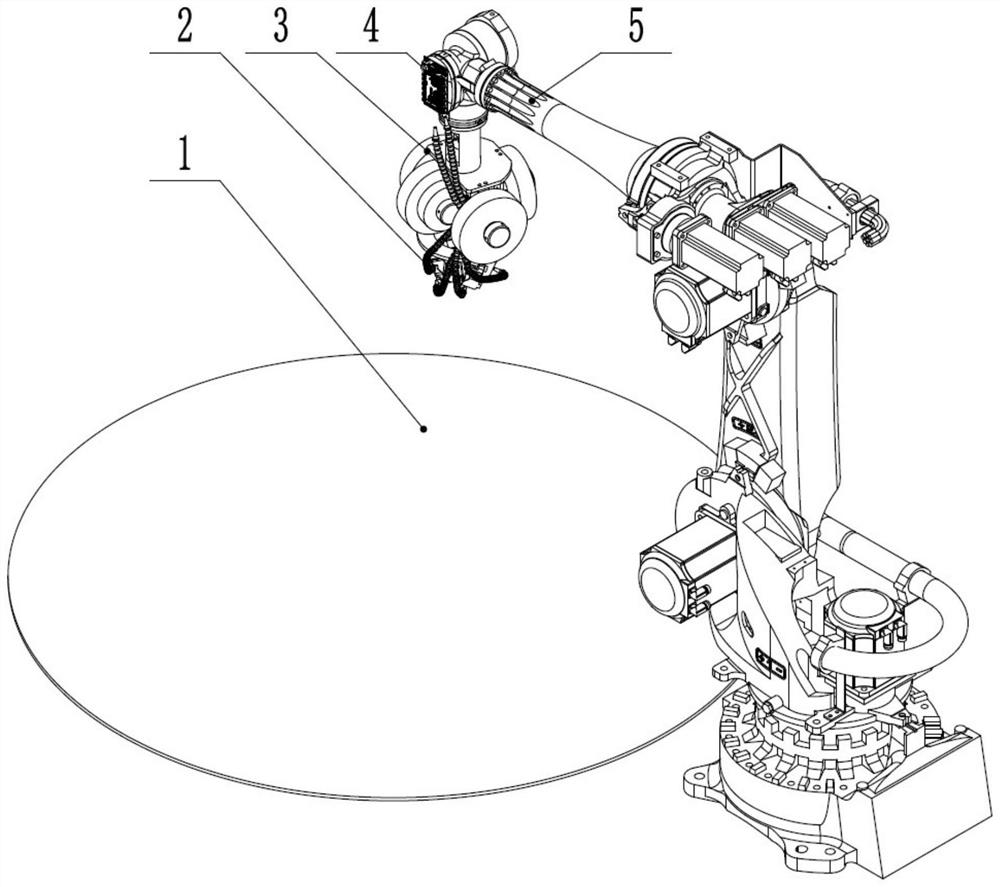

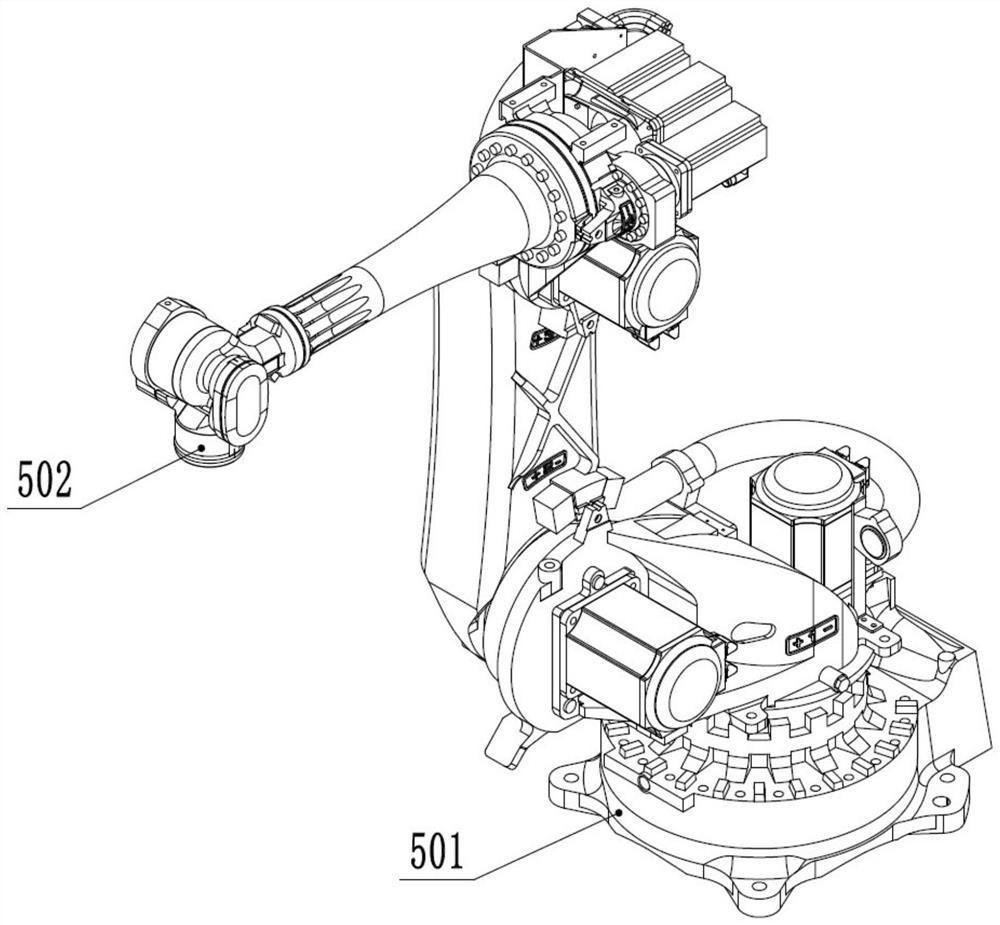

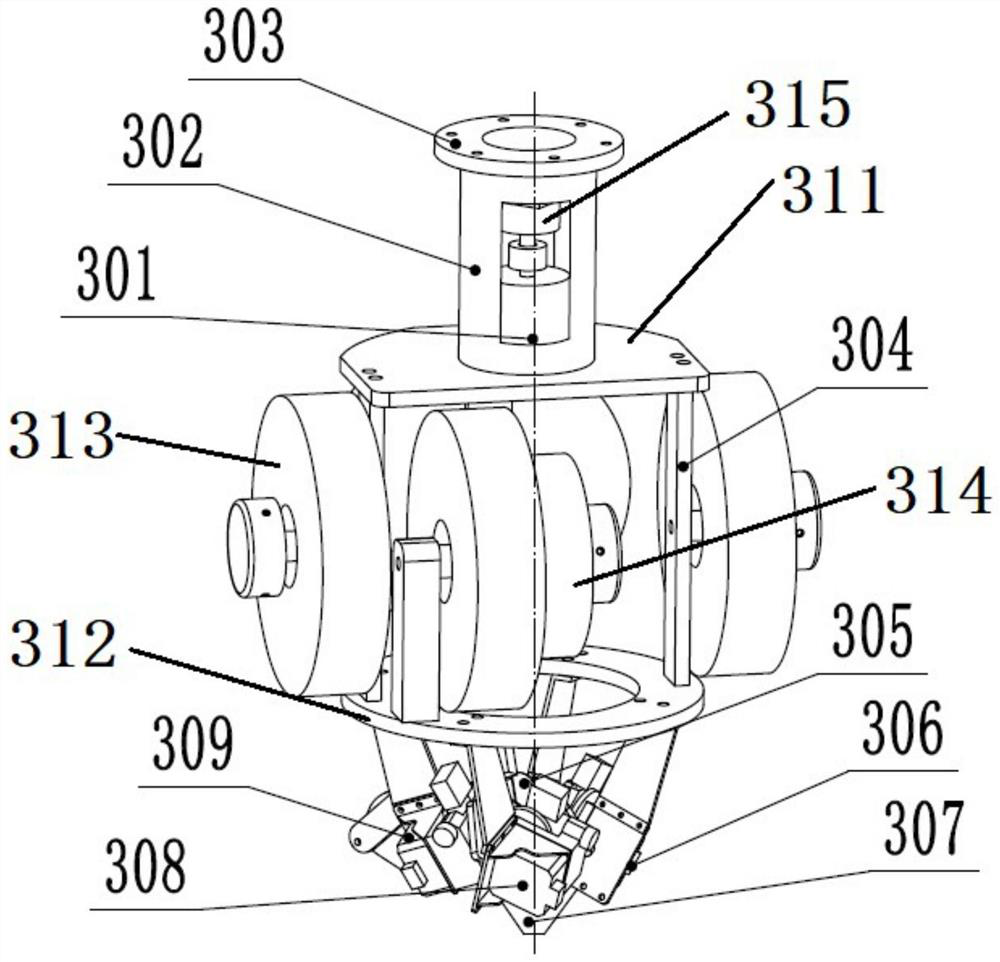

[0037] Such as figure 1 As shown, a robot-assisted large-scale fiber-reinforced heterogeneous multi-material in-situ additive manufacturing system mainly consists of a multi-functional printing platform 1, a multi-channel cooling system 2, a fiber-reinforced multi-material print head 3, a control board 4 and a mechanical Arm 5 constitutes. The multi-material print head 3 is fixed at the end of the mechanical arm 5, and the multi-material print head 3 is provided with a multi-channel cooling system 2; the mechanical arm 5 is provided with a control board 4 near the end, and the multi-material print head is controlled by the control board 4 3 Print on the multi-function printing platform 1.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com