Intelligent processing machine for manufacturing breathing mask

A technology for breathing masks and processing machines, which is applied in the direction of breathing masks, household components, and medical equipment, etc., which can solve the problem of inability to ensure the uniformity of the wall thickness of the breathing mask, affect the processing effect of the breathing mask, and the inability to ensure the uniformity of the release agent, etc. problems, to achieve the effect of shortening processing time, ensuring stability and shortening working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

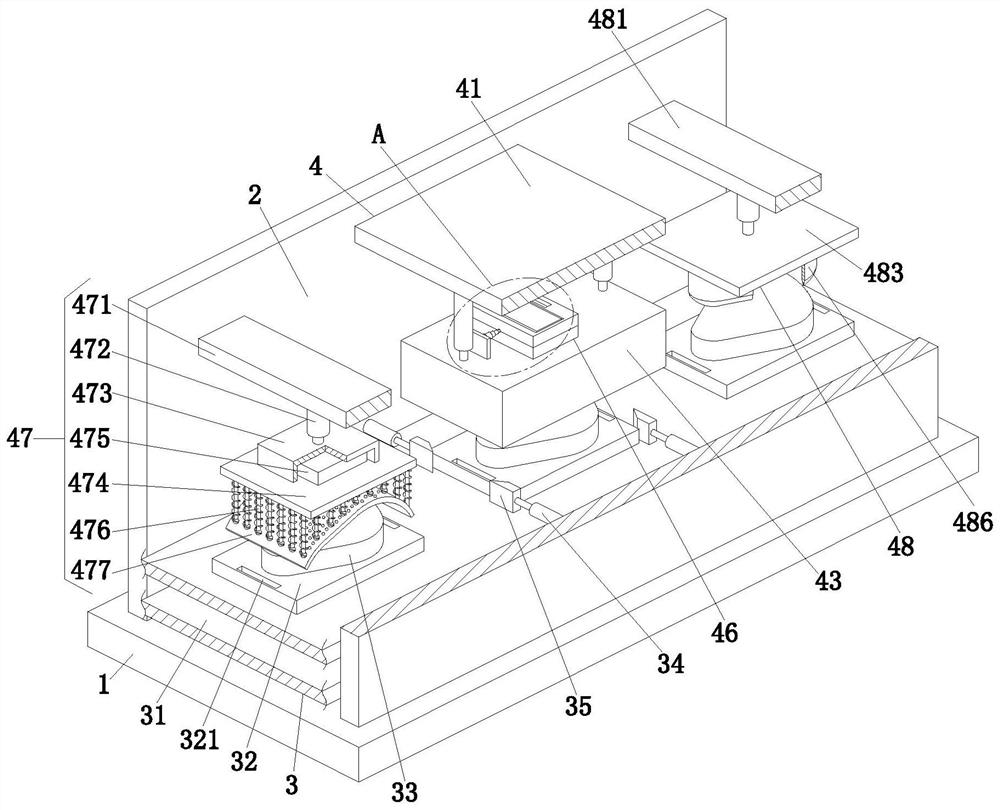

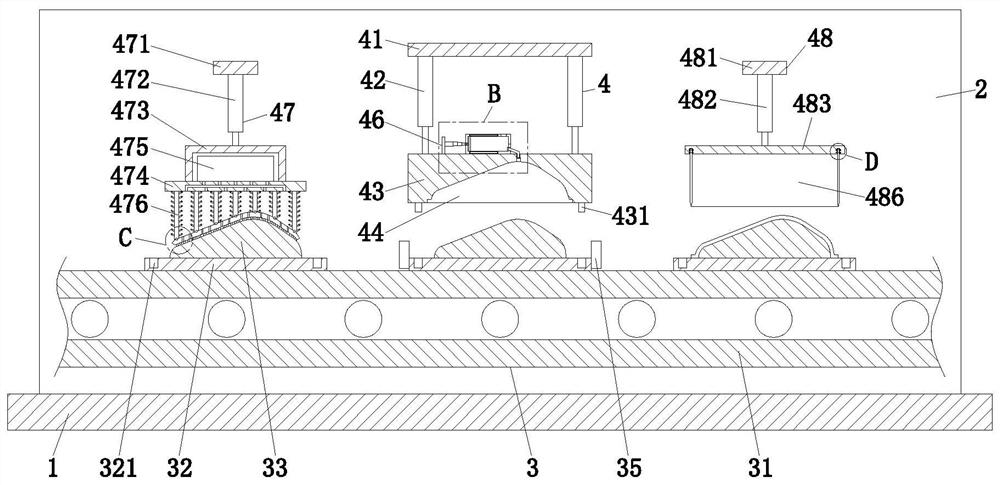

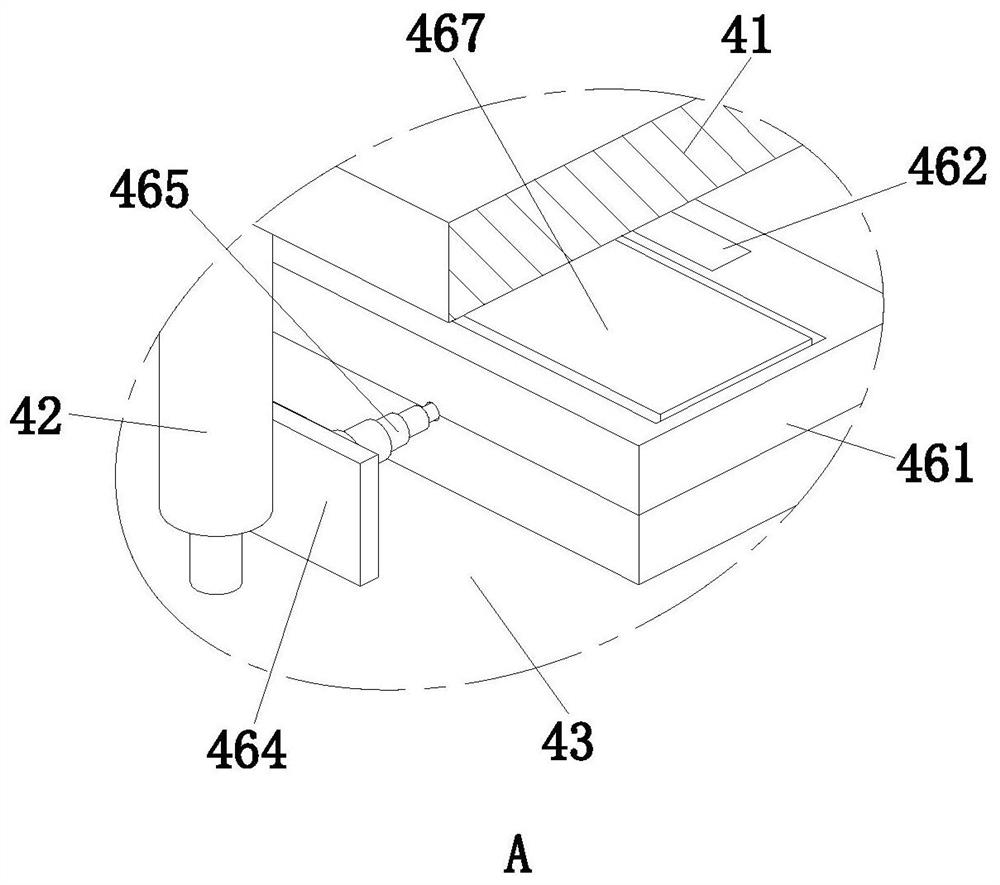

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0033] refer to figure 1 , figure 2 , an intelligent processing machine for manufacturing respiratory masks, comprising a base 1, a support plate 2, a delivery unit 3 and a forming unit 4, the upper end of the base 1 is symmetrically fixed with a support plate 2 front and back, and the opposite end of the support plate 2 is provided with a delivery unit 3 , A molding unit 4 is installed above the conveying unit 3 .

[0034] refer to figure 1 , figure 2 , the conveying unit 3 includes an intermittent conveyor belt 31, a fixed seat 32, a core 33, a supporting cylinder 34 and a clamping block 35, wherein: the intermittent conveyor belt 31 is rotatably arranged under the opposite side of the support plate 2, and the intermittent conveyor belt 31 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com