Preheat rotary injection molding die mechanism for injection molding machine

An injection mold and preheating technology, applied in the field of injection molding machine preheating rotary injection mold mechanism, can solve the problems of long heating time, troublesome, low efficiency, etc., and achieve the effect of good injection molding effect, guaranteed effect and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

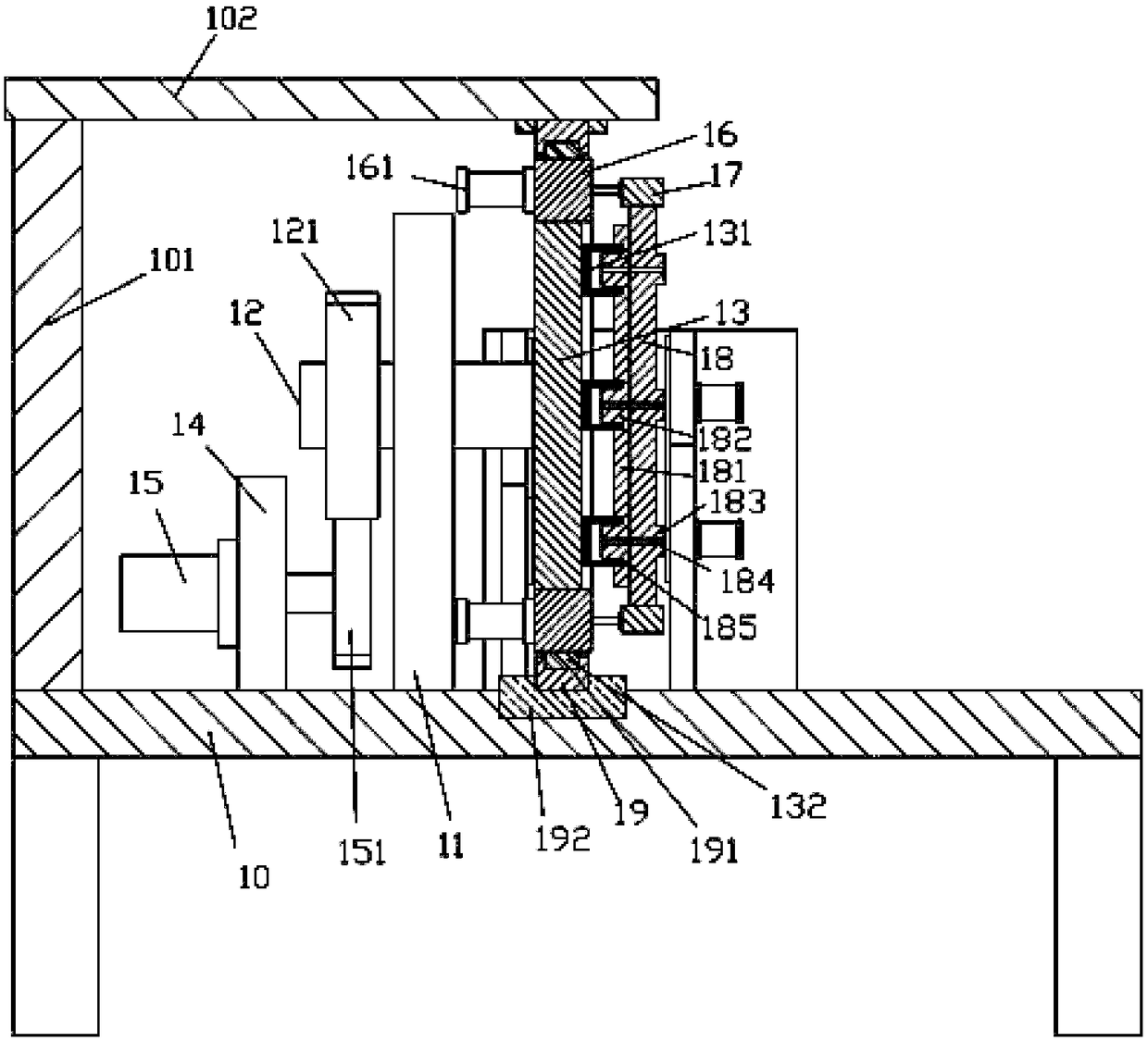

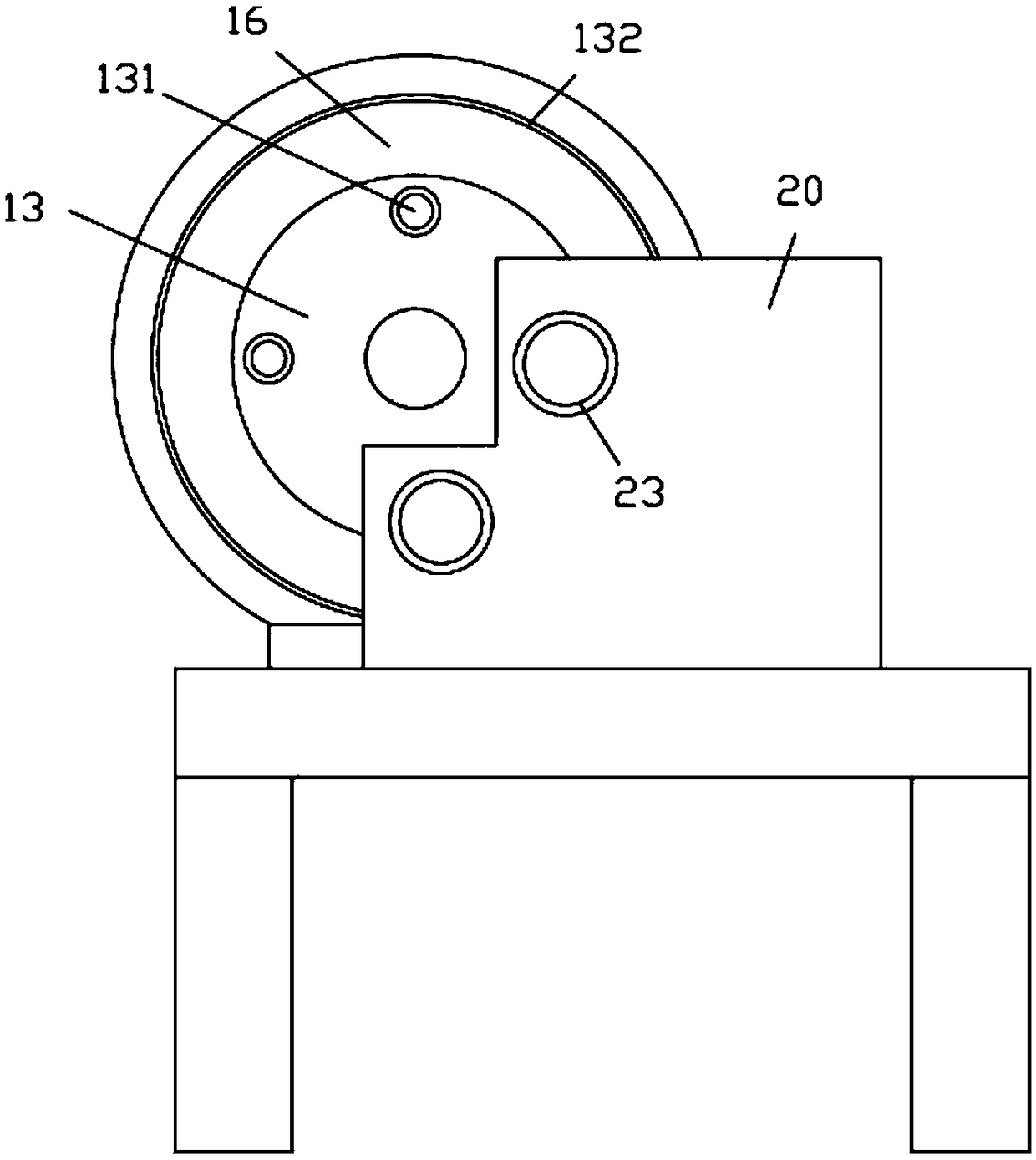

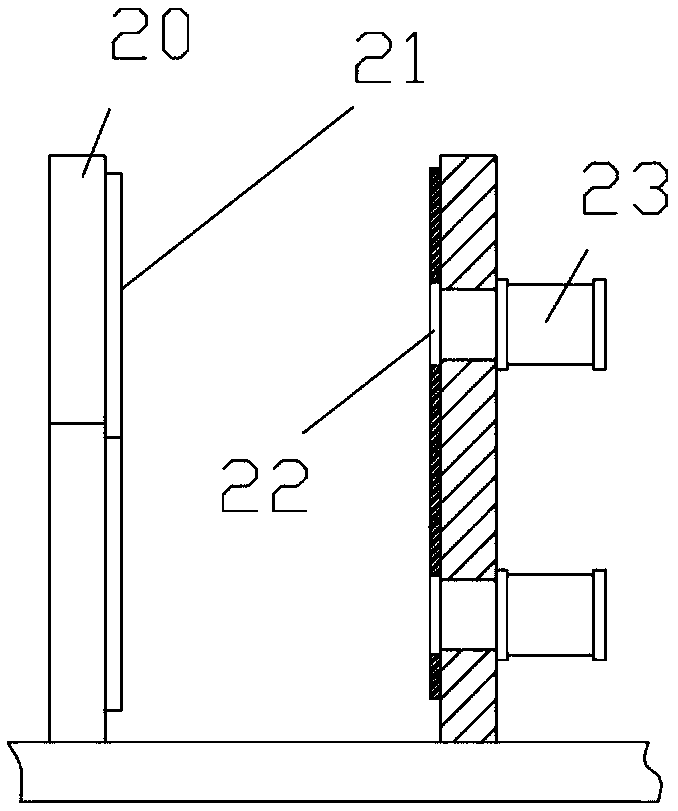

[0019] Examples, see e.g. Figure 1 to Figure 3 As shown, a preheating rotary injection mold mechanism for an injection molding machine includes a frame 10, a main vertical plate 11 is fixed on the top surface of the top plate of the frame 10, and the rear right side of the main vertical plate 20 is Two vertical fixed plates 20 are fixed on the top surface of the top plate of the frame 10, and heating plates 21 are fixed on the opposite wall surfaces of the two vertical fixed plates 20. The middle part of the main vertical plate 11 is hinged with a horizontal main shaft 12, and The right end of the main shaft 12 protrudes from the main vertical plate 11 and is fixed with a rotating disk 13. A plurality of left injection molds 131 are fixed on the right side wall of the rotating disk 13. All the left injection molds 131 are evenly distributed around the horizontal main shaft 12. On the rotating disk 13, the left end of the transverse main shaft 12 stretches out the main vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com