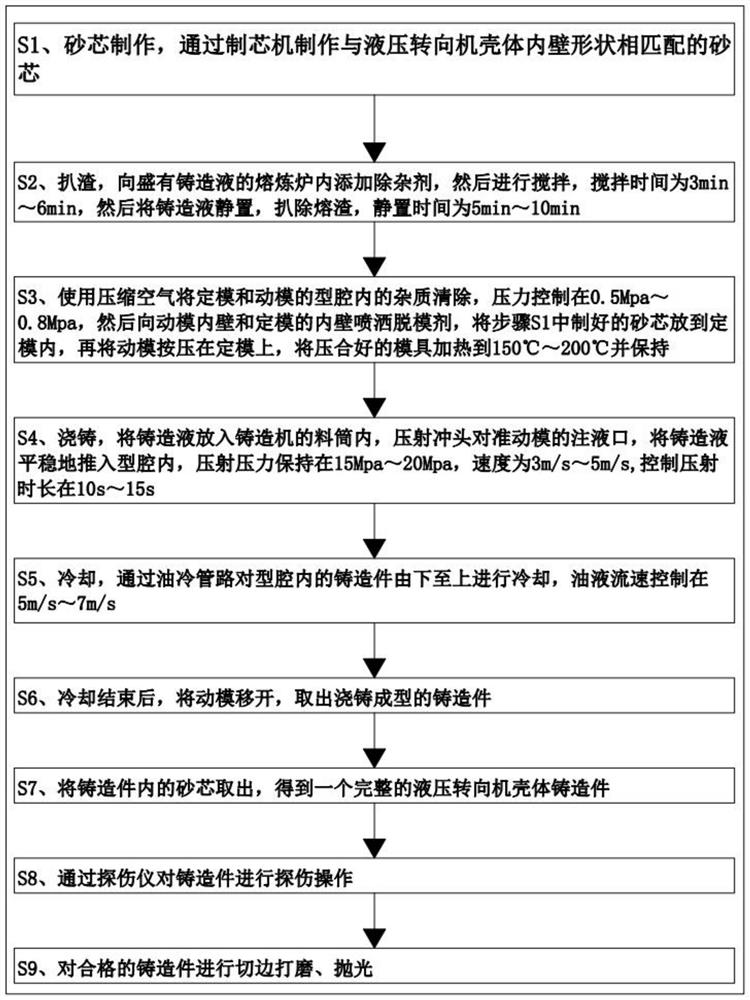

Hydraulic steering gear shell casting mold and casting method

A casting mold and steering machine technology, applied in the field of casting, can solve the problems of poor mold clamping error shell accuracy, low casting efficiency, large physical strength, etc., and achieve the effects of improving casting accuracy, improving casting efficiency, and reducing labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

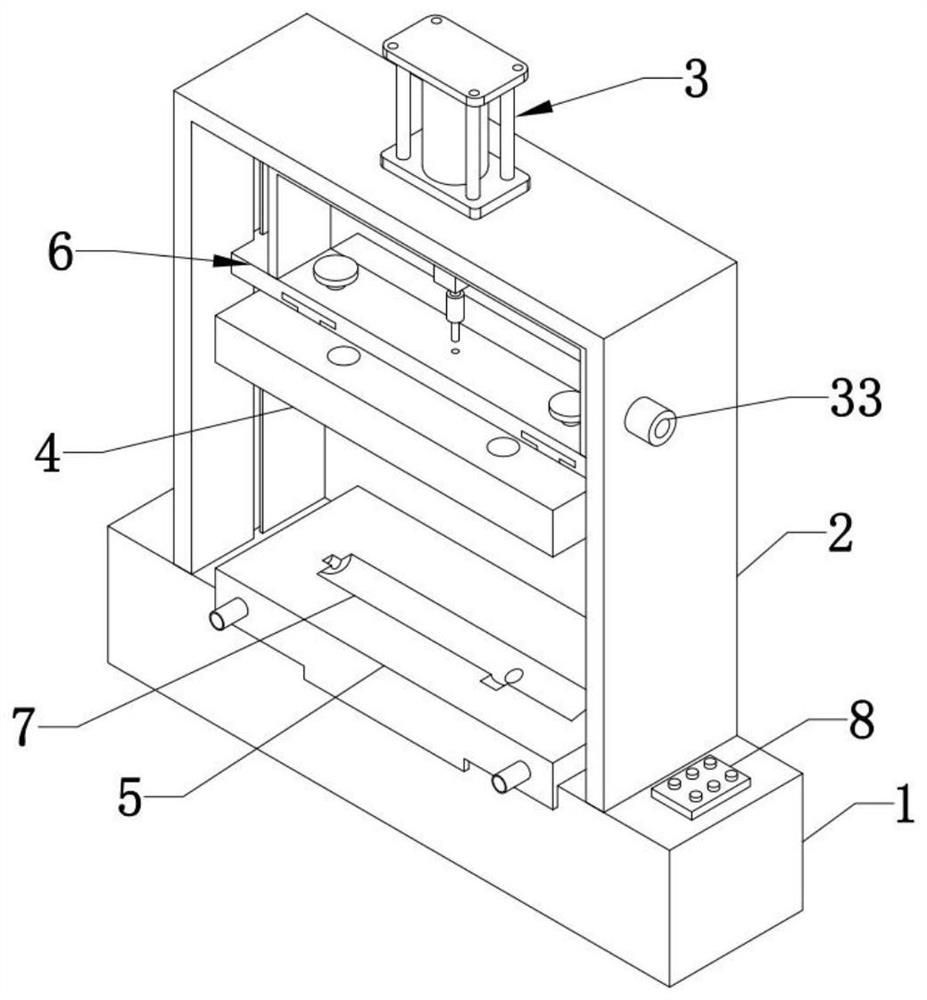

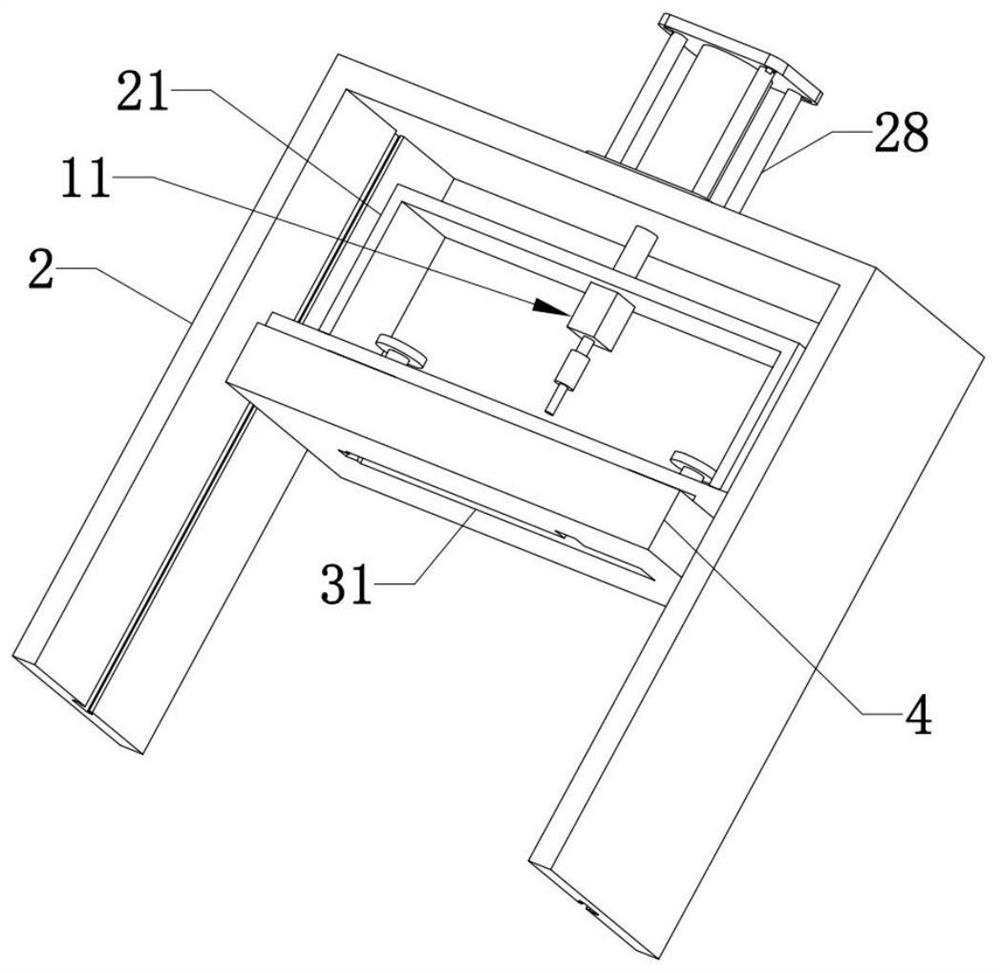

[0059] Such as Figure 2-Figure 9 As shown, a hydraulic steering gear casing casting mold of the present invention includes a base 1, a movable mold 4, a fixed mold 5, a moving assembly 6 for fixing the movable mold 4, and a driving assembly for driving the moving assembly 6 to move up and down 3 and ejection assembly 11 for blanking.

[0060] Among them, such as figure 2 , Figure 7 with Figure 9 As shown, the bottom of the movable mold 4 is provided with a first mold cavity 31, the upper surface of the movable mold 4 is respectively provided with a liquid injection port 29 and an exhaust port 30 communicating with the first mold cavity 31, and the upper surface of the fixed mold 5 There is a second mold cavity 7, and the upper surface of the base 1 is fixed with a gantry 2. In order to improve the cooling speed of the casting, an oil passage 36 is opened inside the fixed mold 5, and the oil inlet of the oil passage 36 is connected with an inlet. The oil pipe 34 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com