A full circle device of stainless steel pipe processing machine

A stainless steel pipe and processing machine technology, applied in the field of stainless steel pipe processing, can solve the problems of slow production efficiency of stainless steel pipe processing, time-consuming addition of stainless steel pipes, and large length of stainless steel pipes. Continuity of operation, effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

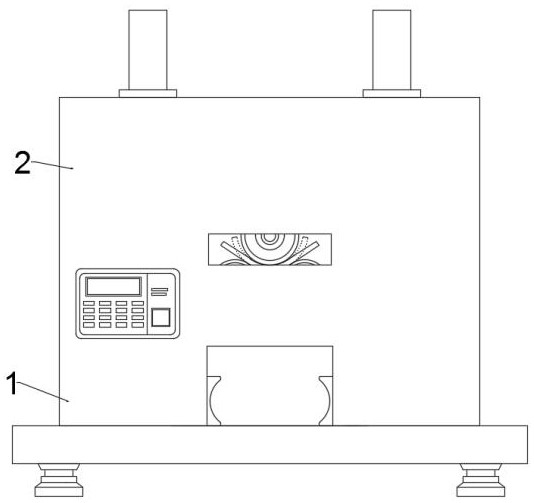

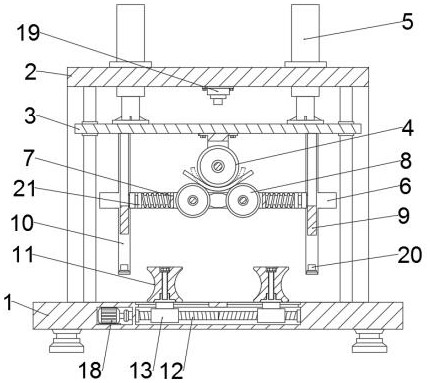

[0026] Example: see Figure 1-8 , a full-circle device for a stainless steel pipe processing machine, comprising a base 1, an installation shell 2 arranged on the top of the base 1, and a lifting plate 3 horizontally movable in the upper part of the installation shell 2, and the middle part of the front end of the installation shell 2 is provided with a feeding The lower part of the front end of the installation shell 2 is provided with a material intake; the middle part of the bottom surface of the lifting plate 3 is longitudinally equipped with a pressure roller 4, and the top surface of the lifting plate 3 is equipped with an electric push cylinder 5 fixedly penetrating through the installation shell 2. The middle part of the inner wall of the front and rear ends of the shell 2 is provided with a stabilizing chute 6 horizontally. The middle part of the stabilizing chute 6 can be used for placing different rectangular blocks. The spacing is reduced and changed, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com