Stator punching sheet, stator core, stator, motor and air conditioning device

A technology of stator punching and stator iron core is applied in the fields of motors and air conditioners, stator punching, stator and stator iron core, and can solve the problems of structural strength of connecting bridges and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

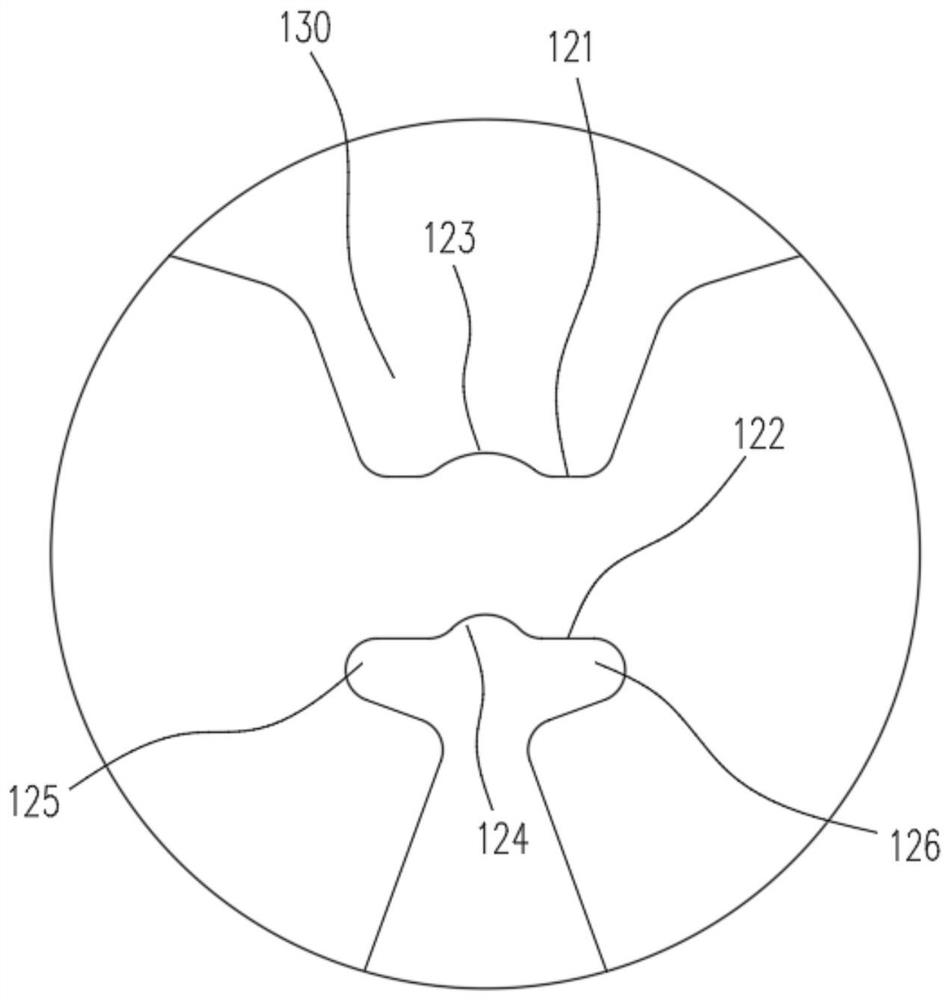

[0054] combine Figure 1-5 as shown, Figure 1-5 The connecting bridge 120 of the middle stator punching sheet and the punching sheet unit 110 have the same structure.

[0055] Such as figure 1 Among them, the stator stamping includes a plurality of stamping units 110 connected in sequence, and a connecting bridge 120 is provided between two adjacent stamping units 110, and the outer peripheral side of each stamping unit 110 is provided with a The positioning groove for positioning, the positioning groove may be a groove structure. Three buckle points 113 are also arranged on the punching unit 110, and the buckle points 113 are rectangular holes. In this embodiment, the punching unit 110 can adopt one of 0.25mm, 0.3mm, 0.35mm, and 0.5mm thick specifications. It is processed from a kind of electrical steel strip plate, and the lamination forming of the stamping monomer 110 is facilitated through the buckle point 113.

[0056] figure 1 It is a schematic diagram of the resul...

Embodiment 2

[0064] combine Figure 6-8 as shown, Image 6 The middle is a schematic diagram of the structure of the second stator stamping in the solution of the present application. In this embodiment, the tooth end of the stamping unit 110 is an arc-shaped structure.

[0065] Such as Image 6 Among them, the stator stamping includes a plurality of stamping units 110 connected in sequence, and a connecting bridge 120 is provided between two adjacent stamping units 110, and the outer peripheral side of each stamping unit 110 is provided with a The positioning groove for positioning, the positioning groove may be a groove structure. Three buckle points 113 are also arranged on the punching unit 110, and the buckle points 113 are rectangular holes. In this embodiment, the punching unit 110 can adopt one of 0.25mm, 0.3mm, 0.35mm, and 0.5mm thick specifications. It is processed from a kind of electrical steel strip plate, and the lamination forming of the stamping monomer 110 is facilitate...

Embodiment 3

[0071] combine Figure 9-11 as shown, Figure 9 The middle is a schematic diagram of the structure of the third stator punching in this application scheme. In this embodiment, the tooth end of the punching unit 110 is an arc-shaped structure, and the root of the tooth of the punching unit 110 is a straight-edge structure, which is convenient Die stamping and winding equipment line up to improve the utilization rate of iron core materials.

[0072] Such as Figure 9 Among them, the stator stamping includes a plurality of stamping units 110 connected in sequence, and a connecting bridge 120 is provided between two adjacent stamping units 110, and the outer peripheral side of each stamping unit 110 is provided with a The positioning groove for positioning, the positioning groove may be a groove structure. Three buckle points 113 are also arranged on the punching unit 110, and the buckle points 113 are rectangular holes. In this embodiment, the punching unit 110 can adopt one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com