Crushing device for tablet production, and using method thereof

A crushing device and tablet technology, which is applied in grain processing, etc., can solve the problems of increased workload of medical staff, long time for crushing and grinding, and poor quality of tablets, and achieve good grinding quality, convenient operation, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

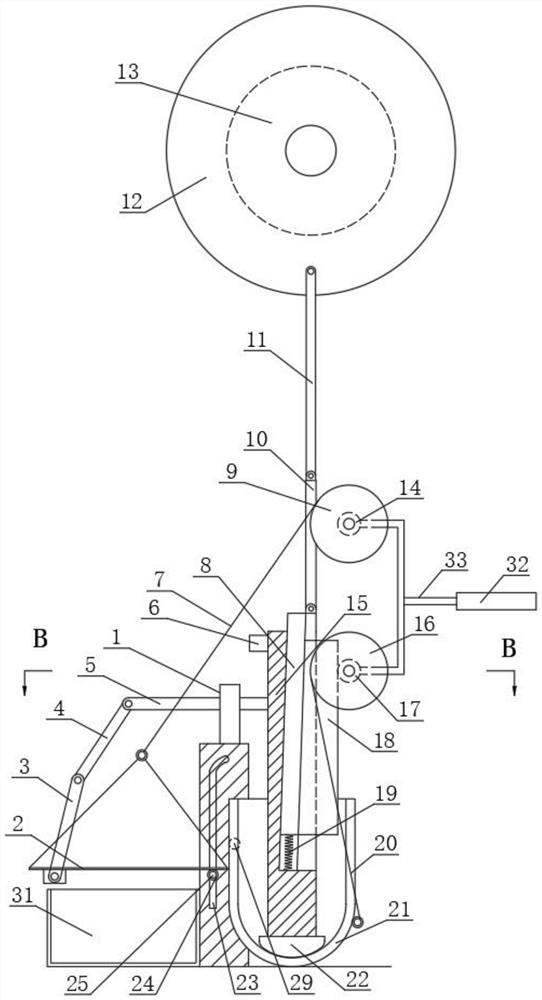

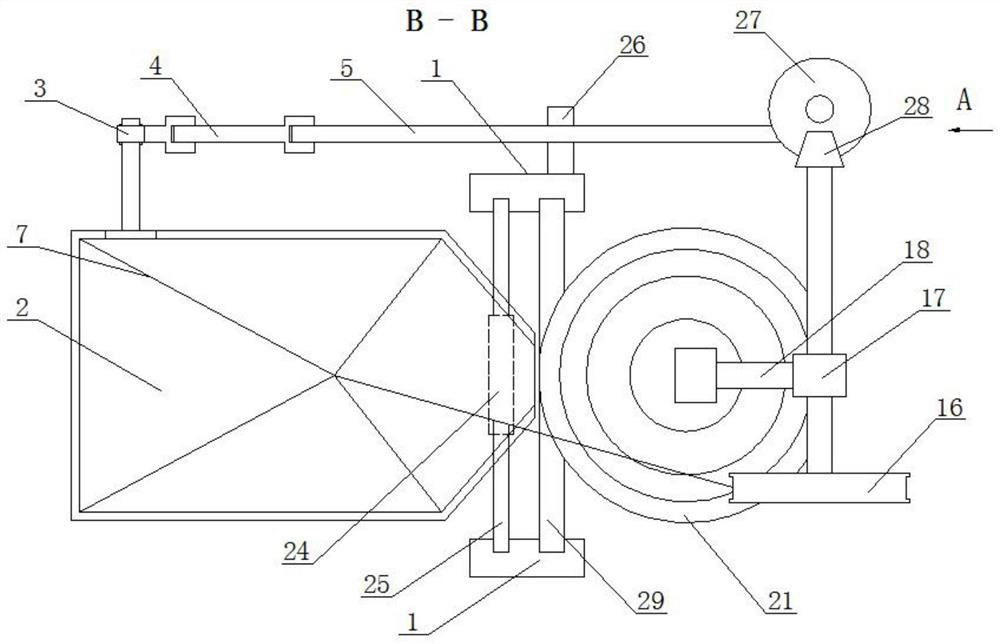

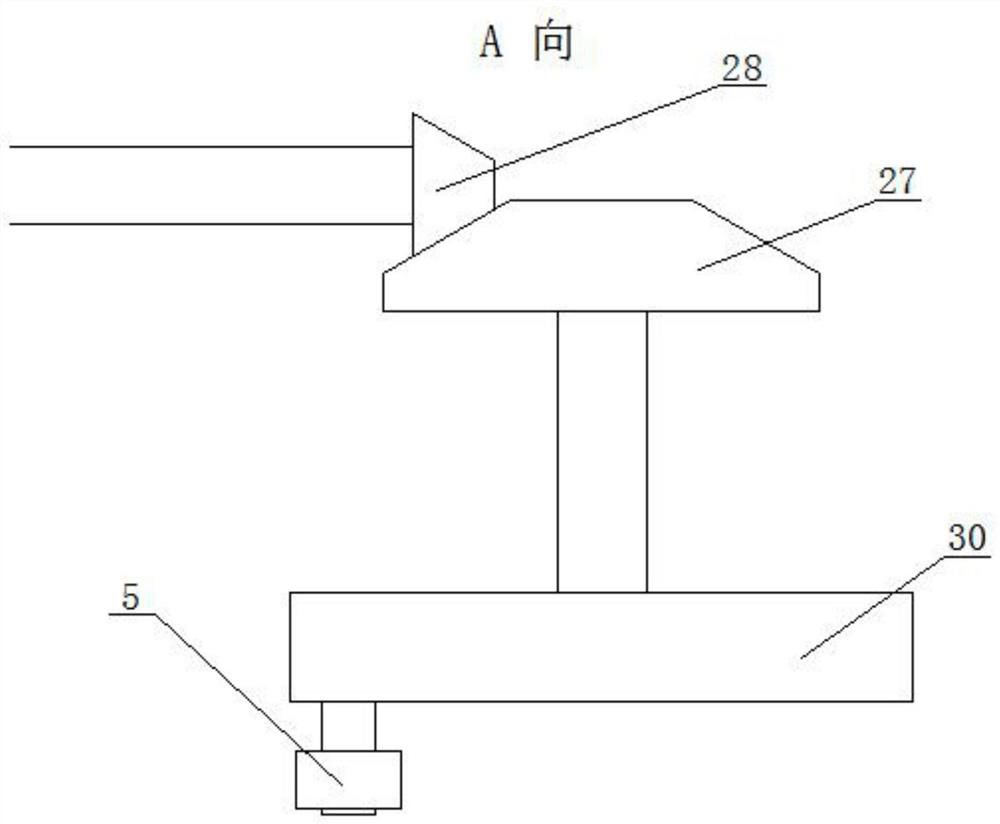

[0037] like Figure 1-8 As shown, this embodiment proposes a crushing device for tablet production, which includes a support frame 1 and a collection box 31 , and the support frame 1 is rotatably connected to a medicine tank 21 through a tank rotating shaft 29 . The collection box 31 is arranged on one side of the medicine tank 21, the tank rotating shaft 29 is arranged on the side of the medicine tank 21 close to the collecting box 31, and the tank rotating shaft 29 is arranged above the medicine tank 21, so that when the medicine tank 21 rotates around the tank rotating shaft 29 , the material in the medicine tank 21 can be poured out.

[0038]The support frame 1 is fixedly connected with a fixed sliding sleeve 6, and the fixed sliding sleeve 6 is slidably connected with a sliding rod 15. The medicine tank 21 is provided with a drug hammer 22 connected to the sliding rod 15. The fixed sliding sleeve 6 acts to move the sliding rod 15. To limit the position, so that the slidi...

Embodiment 2

[0068] like Figure 1-8 As shown, this embodiment proposes a screening and grinding device for tablet production, which includes a support frame 1 and a collection box 31 , and the support frame 1 is rotatably connected to a medicine tank 21 through a tank rotating shaft 29 . The collection box 31 is arranged on one side of the medicine tank 21, the tank rotating shaft 29 is arranged on the side of the medicine tank 21 close to the collecting box 31, and the tank rotating shaft 29 is arranged above the medicine tank 21, so that when the medicine tank 21 rotates around the tank rotating shaft 29 , the material in the medicine tank 21 can be poured out.

[0069] A screen 2 is arranged on one side of the medicine tank 21, and the screen 2 is arranged above the collection box 31. The medicine tank 21 is connected with a moving mechanism, and the moving mechanism is used to drive the medicine tank 21 to rotate so as to pour the materials in the medicine tank 21 into the screen. 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com