A filter press device and method for producing p-tert-butylcyclohexanol

A technology for p-tert-butyl and cyclohexanol, which is applied in the field of pressure filter equipment for production of p-tert-butyl cyclohexanol, can solve the problems of difficult desorption of filter press plate and easy adhesion of materials, and achieve the solution of difficult desorption and reduce waste , Improve the scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

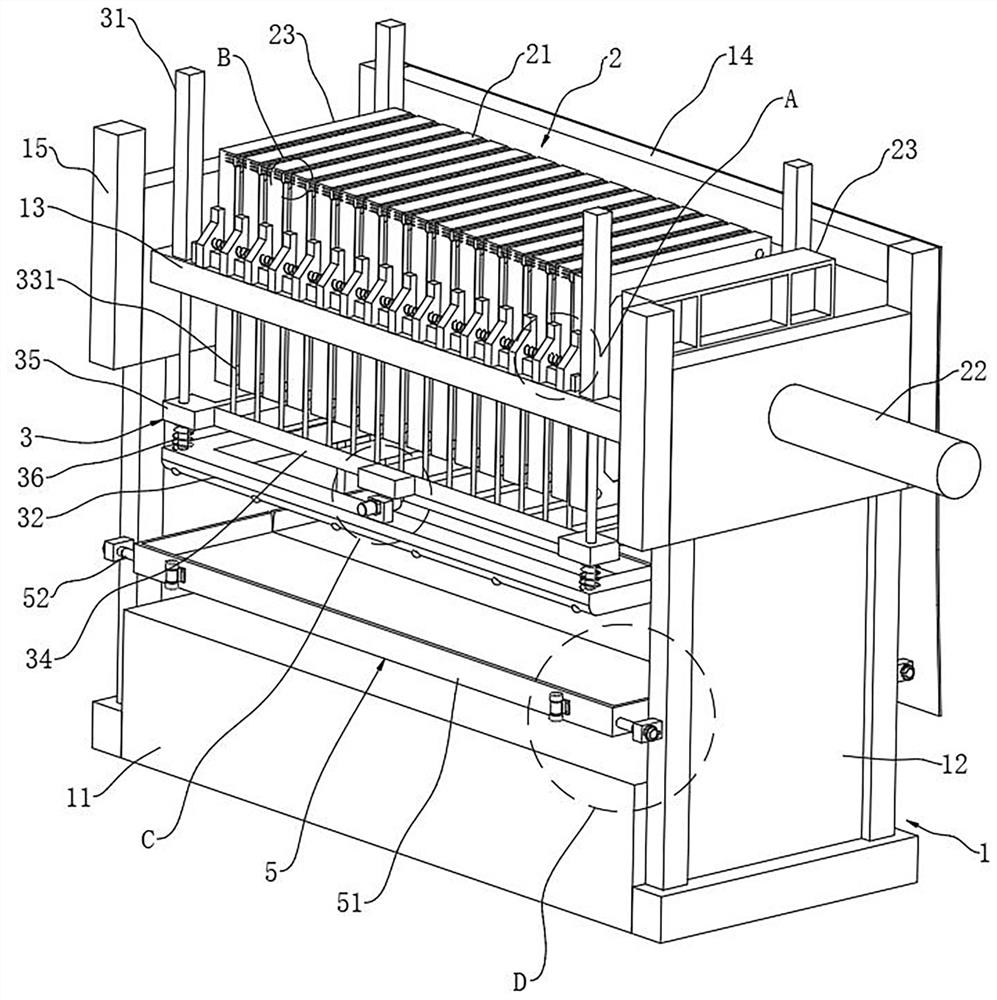

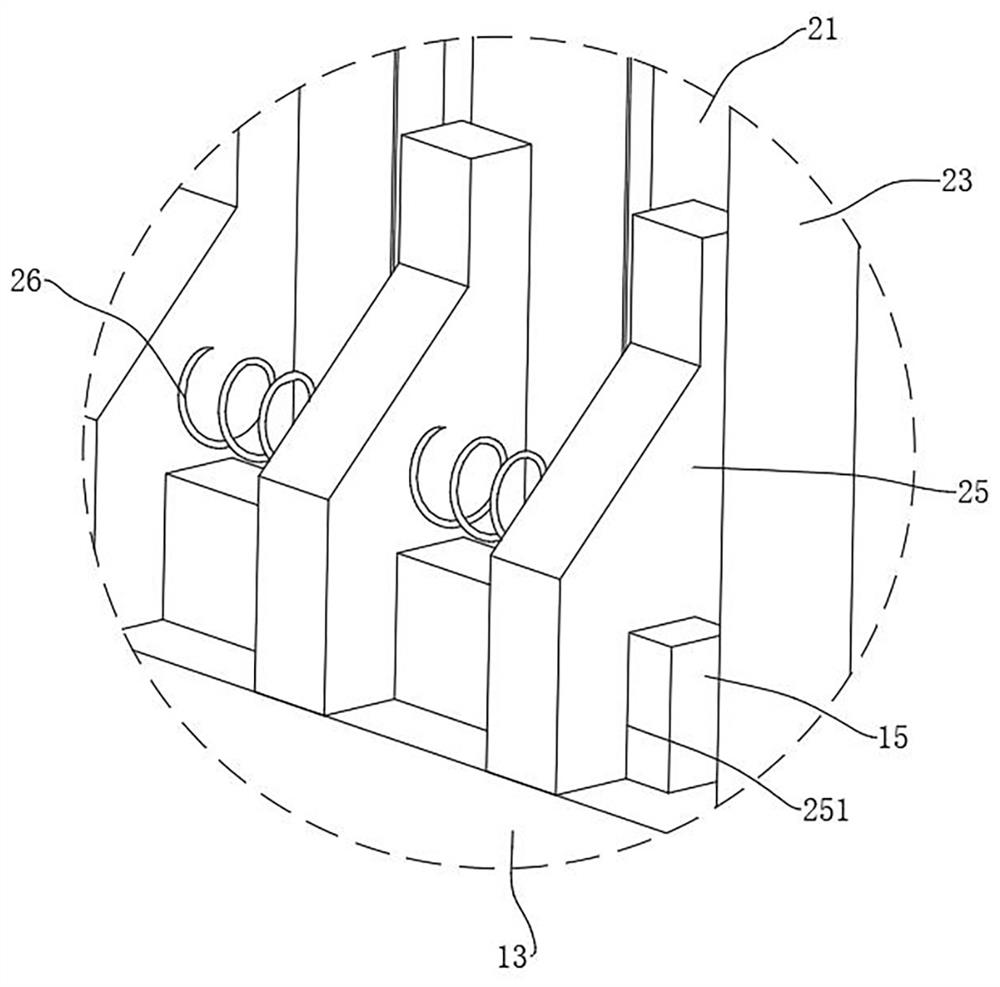

[0026] The disclosure of the embodiment of the present application provides a filter press device and method for producing tert-butylcyclohexanol. After the material is squeezed and filtered by the filter press mechanism 2, the movable frame 32 is driven down by the pusher cylinder 31, and the filter press is passed through the pusher brush. 332 scrapes the adjacent filter press plate 21, which solves the problem that the material is easy to adhere to the filter press plate 21 and is not easy to detach when the filter press device in the prior art performs press filtration on the material, and realizes that it can be easily processed The effect that filter press plate 21 cleans up in time.

[0027] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

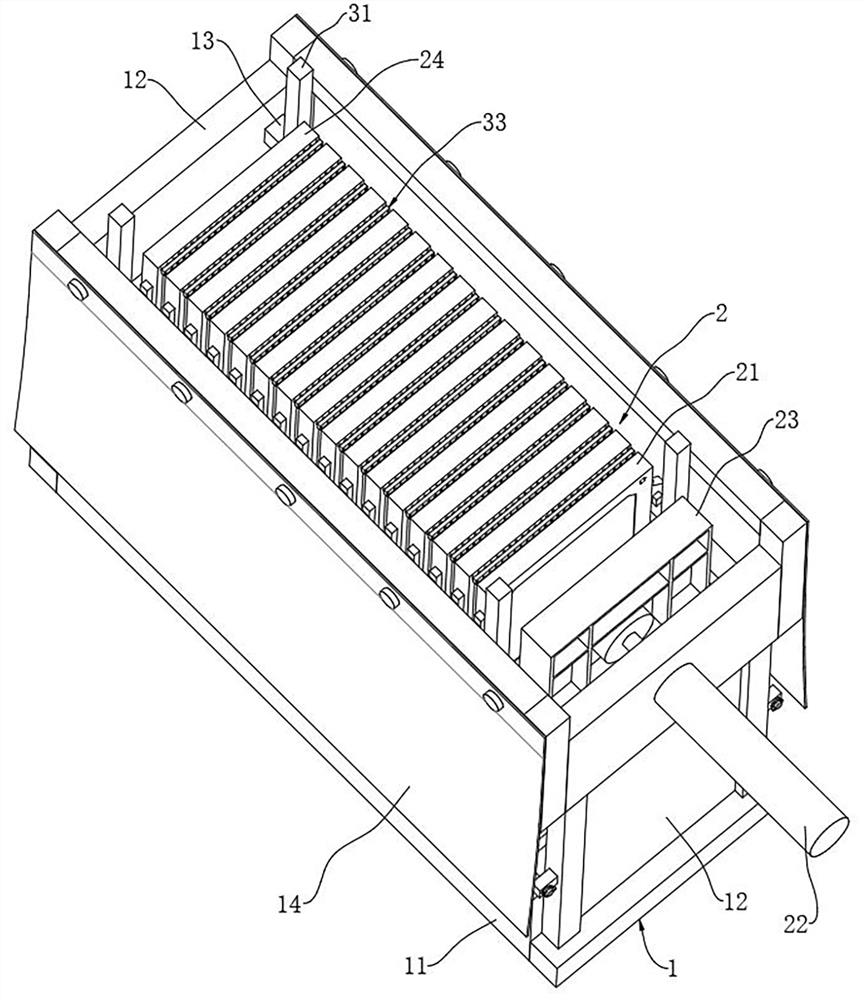

[0028] refer to figure 1 , figure 2 On the one hand,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com