Machine tool descending stability control method and system and tractor

A stability control method and technology, applied in the field of tractors, can solve the problems of starting shock, easily damaged implements, shocks, etc., and achieve the effects of small stopping shock, stable starting and good fretting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

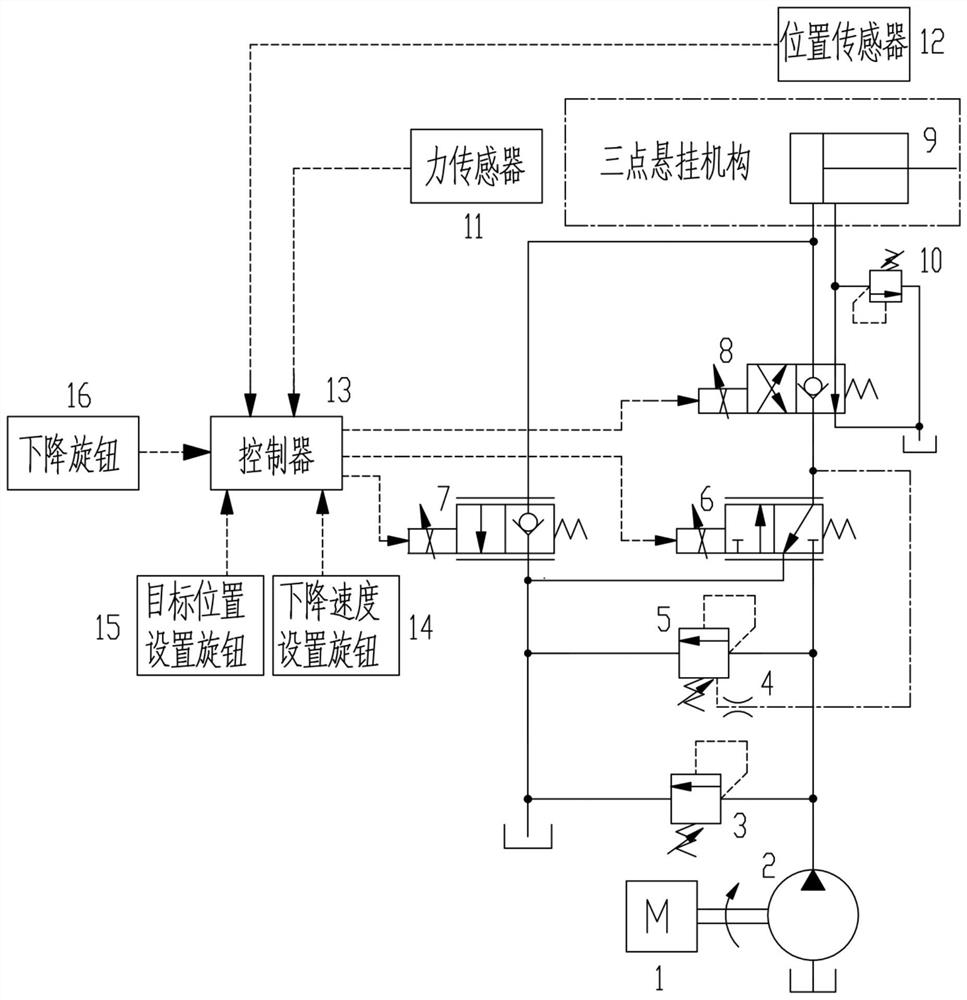

[0030] Such as figure 1 As shown, a control system for lowering stability of implements includes: a main pump 2 driven by an engine 1, the inlet of the main pump 1 communicates with the fuel tank, the outlet of the main pump 1 is respectively connected to the inlet and fixed position of the main overflow valve 3 The inlet of the differential relief valve 5 is connected with the inlet of the machine control valve 6; the outlet of the main relief valve 3 and the outlet of the differential relief valve 5 are connected with the oil tank; the oil return port of the machine control valve 6 is in normal position and connected with the oil tank ; The oil outlet of the implement control valve 6 is connected to the spring chamber of the differential relief valve 5 through the steady-state throttle valve 4, and the oil outlet of the implement control valve 6 is connected with the inlet of the switching valve 8 simultaneously; the opening of the switching valve 8 The oil outlet is connect...

Embodiment 2

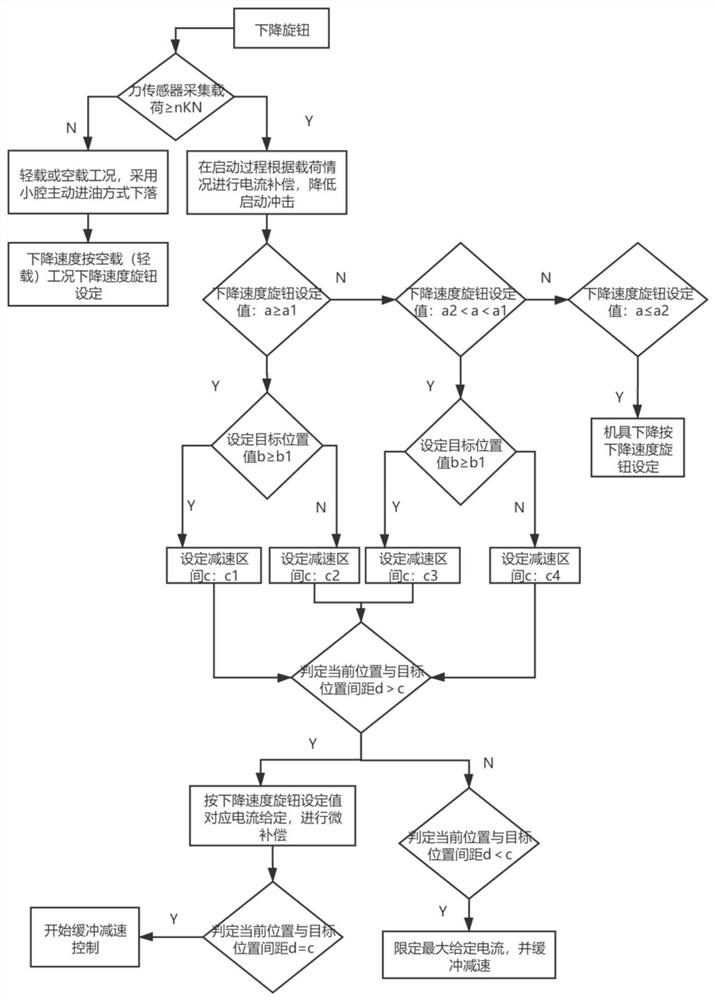

[0034] Such as figure 1 , figure 2 As shown, based on the implement descending stability control system described in Embodiment 1, this embodiment provides a implement descending stabilization control method, adopting the implement descending stabilization control system described in Embodiment 1, including: descending the knob to the controller Input the descending command; the controller reads the load information of the suspension mechanism collected by the force sensor and compares it with the set value; when the load information of the suspension mechanism collected by the force sensor is less than the set value, the controller selects no-load or The light load mode controls the lowering of the implement; when the load information of the suspension mechanism collected by the force sensor is greater than or equal to the set value, the controller selects the medium load / heavy load mode to control the lowering of the implement.

[0035] When the load information of the sus...

Embodiment 3

[0070] Based on the implement lowering stability control system described in the first embodiment and the implement lowering stability control method described in the second embodiment, this embodiment provides a tractor, and the tractor is equipped with the implement lowering stability control method described in the first embodiment. Stability control system, and control the stable decline of the implement based on a method for stabilizing the descent of the implement described in the second embodiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com