Double suction pump capable of preventing water accumulation in groove

A technology for double-suction pumps and water storage tanks, which is applied to non-volume pumps, pumps, components of pumping devices for elastic fluids, etc., and can solve the problem of reducing the service life of double-suction pumps, damage to parts, and grooves in double-suction pumps Problems such as stagnant water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

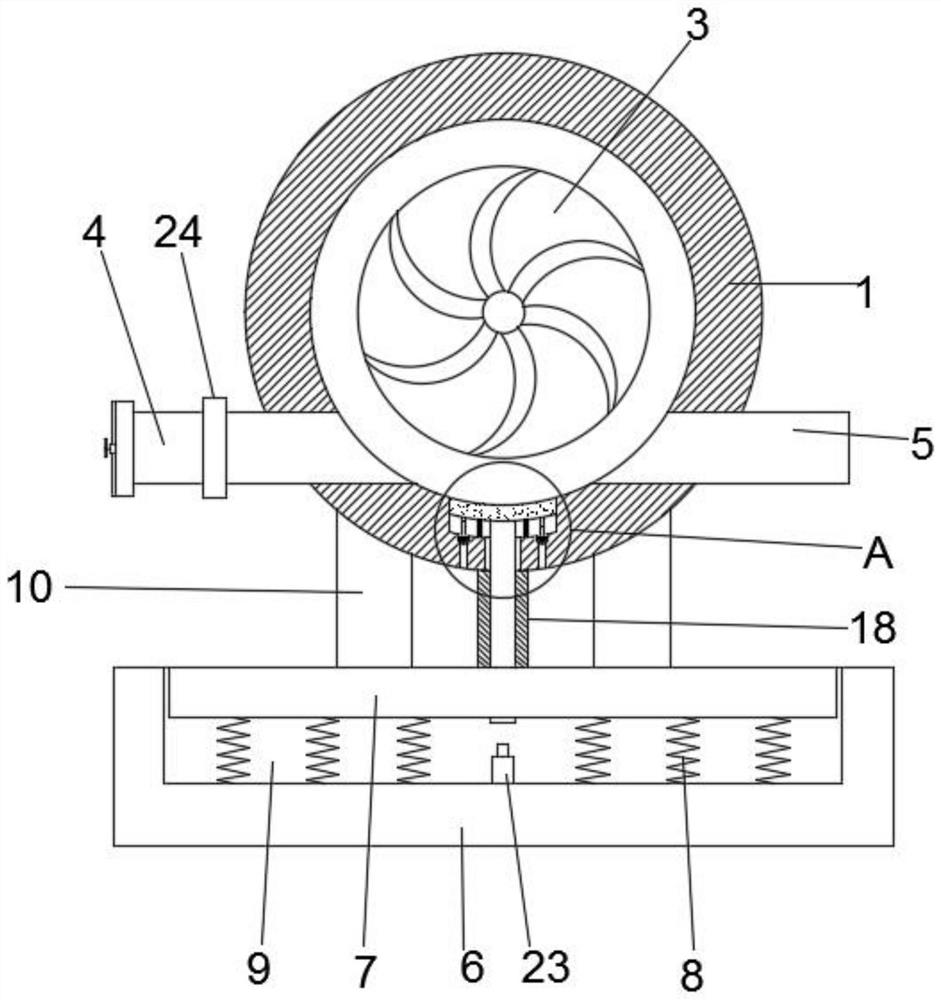

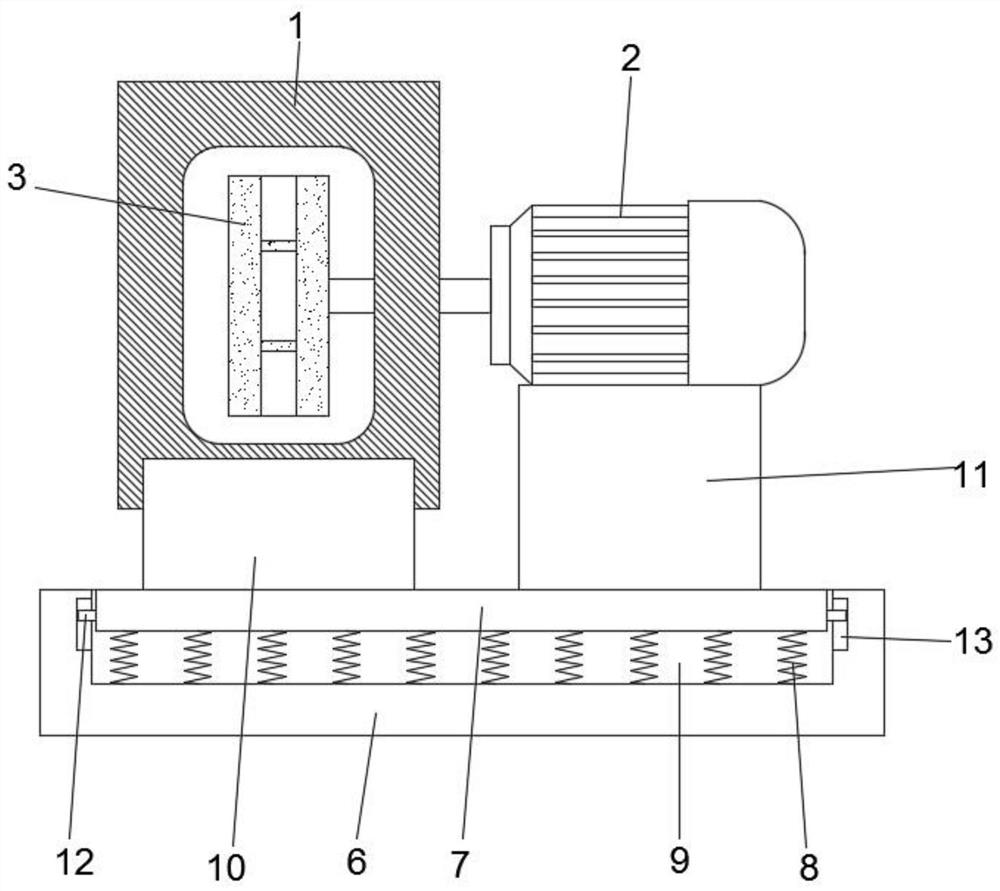

[0027] Such as Figure 1-4 As shown, a double-suction pump for preventing ponding in grooves includes a pump casing 1 and a motor 2, the pump body 1 is provided with an impeller 3 inside, and the output shaft of the motor 2 runs through the pump casing 1 and is fixedly connected to the impeller 3 The two sides of the pump casing 1 are respectively provided with a water inlet pipe 4 and a drain pipe 5. The motor 2 drives the impeller 3 to rotate counterclockwise. ;

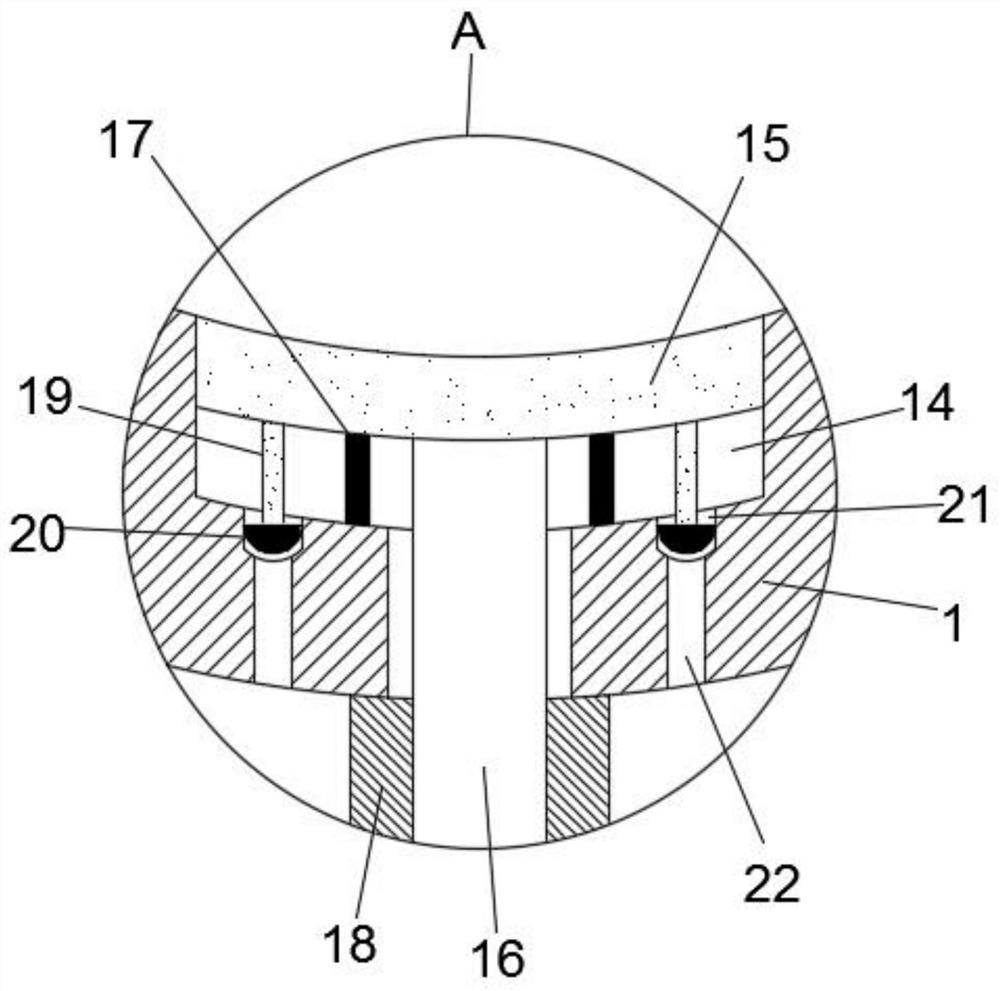

[0028] The bottom side of the inner wall of the pump casing 1 is provided with a water tank 14, and a partition 15 is movably connected in the water tank 14, and a guide rod 16 is installed at the bottom of the partition 15, and the bottom end of the guide rod 16 penetrates and extends to On the outside of the pump casing 1, the bottom end of the guide rod 16 penetrates and extends to the lower side of the buffer plate 7. An electric push rod 23 is fixedly installed in the buffer tank 9, and the telescopic end of ...

Embodiment 2

[0039] On the basis of Example 1, such as Figure 5-8 As shown; the filter screen 32 is fixedly connected to one end of the straight rod 29 away from the side of the impeller 3, and the other end of the straight rod 29 is fixedly installed with a mounting block 33, and the outside of the mounting block 33 is fixedly mounted with several groups of connecting bars 27, The connecting bar 27 is arranged in a ring around the center of the mounting block 33, and a sleeve 28 is fixedly installed on one side of the connecting bar 27 near the filter screen 32. The inside of the sleeve 28 is provided with a built-in screw thread, and the outside of the water inlet pipe 4 is provided with There are external threads, and the sleeve 28 is connected to the water inlet pipe 4 through threads. The water inlet pipe 4 is fixedly installed with a fixing plate 31 inside, and the filter screen 32 abuts against the fixing plate 31 .

[0040] Specifically, the filter screen 32 needs to be installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com