Multi-layer aerial corridor for high-rise steel structure building and construction method of multi-layer aerial corridor

A technology for steel structures and corridors, applied in buildings, building components, building types, etc., can solve the problems of low safety factor, inconvenient construction, large volume and quality of structural components, etc. The effect of force equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is attached Figure 1-8 The application is described in further detail.

[0046] The embodiment of the present application discloses a multi-storey aerial corridor of a high-rise steel structure building.

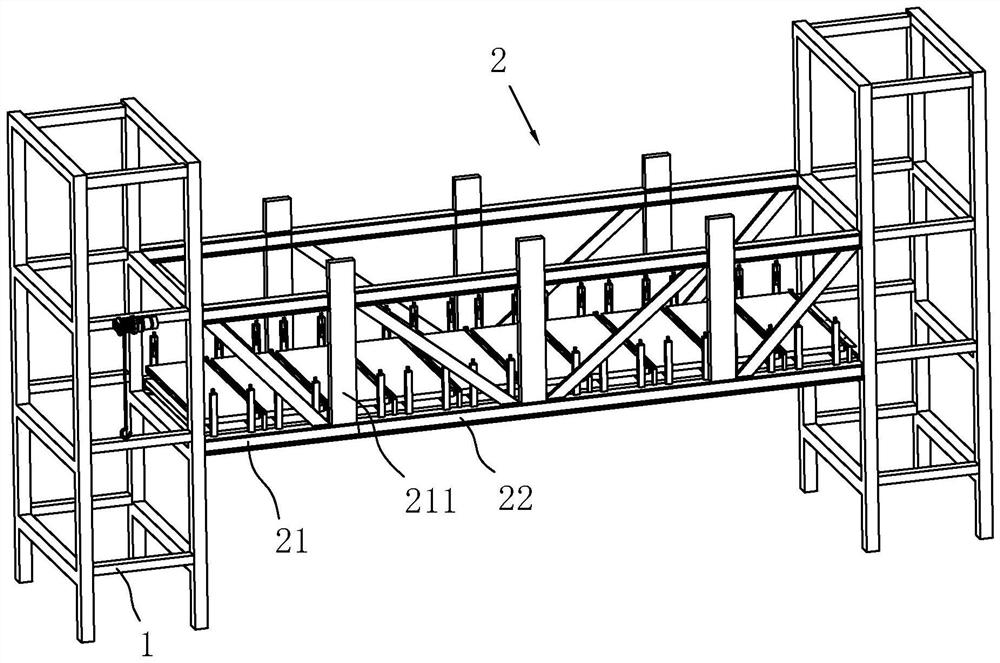

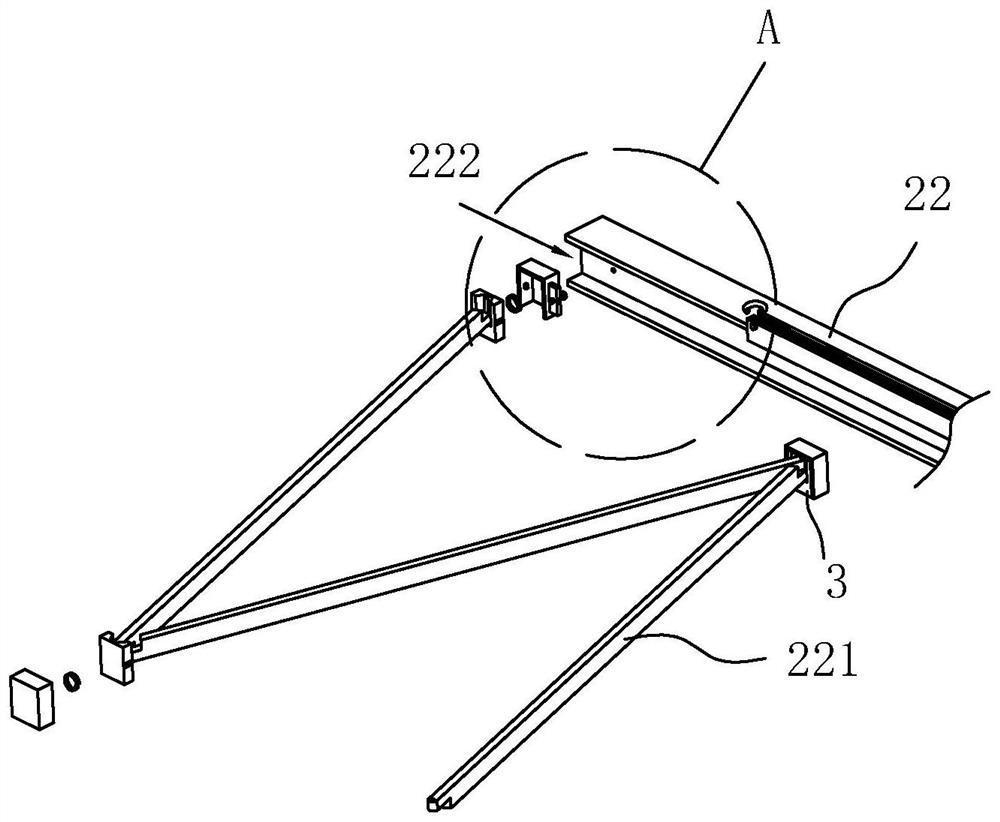

[0047] refer to figure 1 , a multi-storey aerial corridor of a high-rise steel structure building, including a corridor body 2 and two towers 1, the corridor body 2 includes a cantilever beam 21 and two beams 22, the beam 22 is made of H-shaped steel, and the cantilever beam 21 is fixed It is arranged on the tower 1, and the two ends of the beam 22 are fixedly connected with the cantilever beams 21 on the two towers 1 respectively.

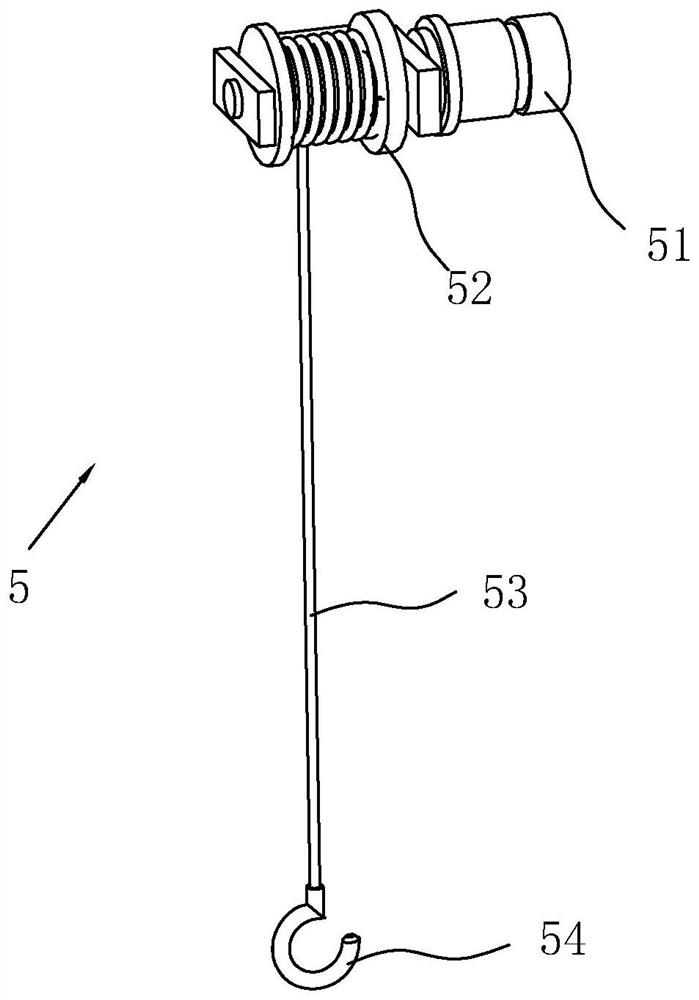

[0048] refer to figure 2 , the tower 1 is provided with a hoisting assembly 5 for hoisting structural parts, the hoisting assembly 5 includes a motor 51, a reel 52, a cable 53 and a hook 54, the reel 52 is rotatably arranged on the tower 1, and the motor 51 is fixedly arranged On the tower 1, the dragline 53 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com