A roof gutter and its construction method

A roofing and gutter technology, applied in the direction of roofing, roof covering, roof insulation materials, etc., can solve the problems of low labor efficiency of construction personnel and cumbersome gutter construction operation process, achieve high construction operation efficiency and improve installation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Attached to the following Figure 1-6 This application will be described in further detail.

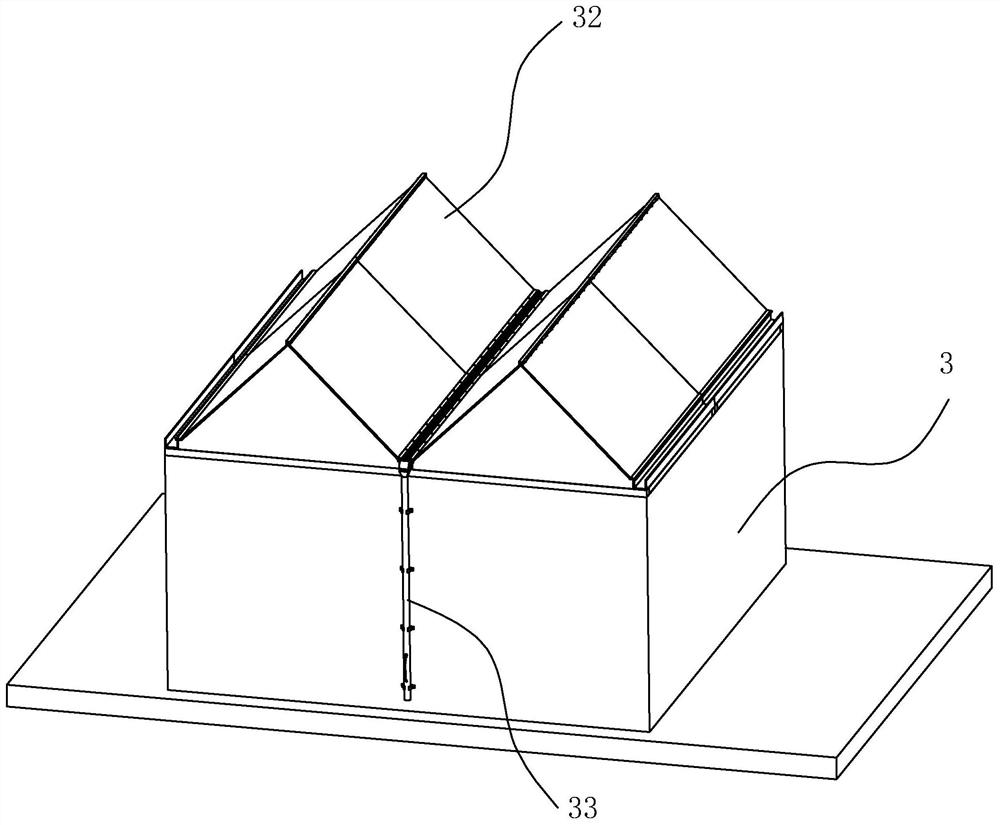

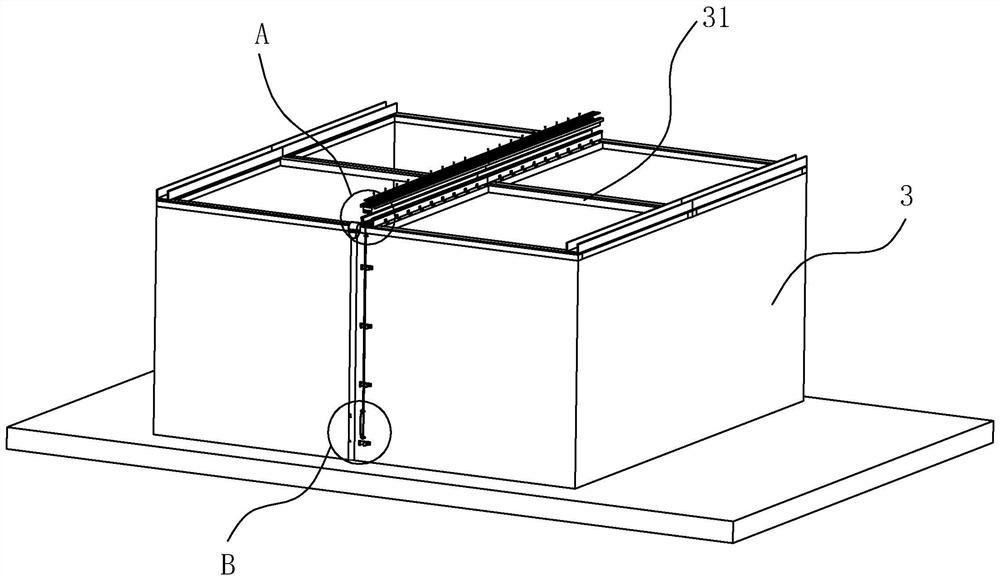

[0041] The embodiments of the present application disclose a roof gutter and a construction method thereof. refer to figure 1 , a steel structure house 3 is installed on the ground, and each group of walls of the house 3 is a prefabricated sheet, each group of sheets is preferably a galvanized sheet, and two layers of galvanized sheets are sandwiched with polyurethane foam. This kind of house 3 is of sloping roof type, and this kind of roof gutter is located at the saddle of each group of sloping roof houses 3 . The extension direction of the roof gutter is parallel to the beams of the sloping roof on both sides. Several groups of waterproof boards 32 of the same specification are laid on the uppers on both sides of the roof, and each group of waterproof boards 32 is continuously paved.

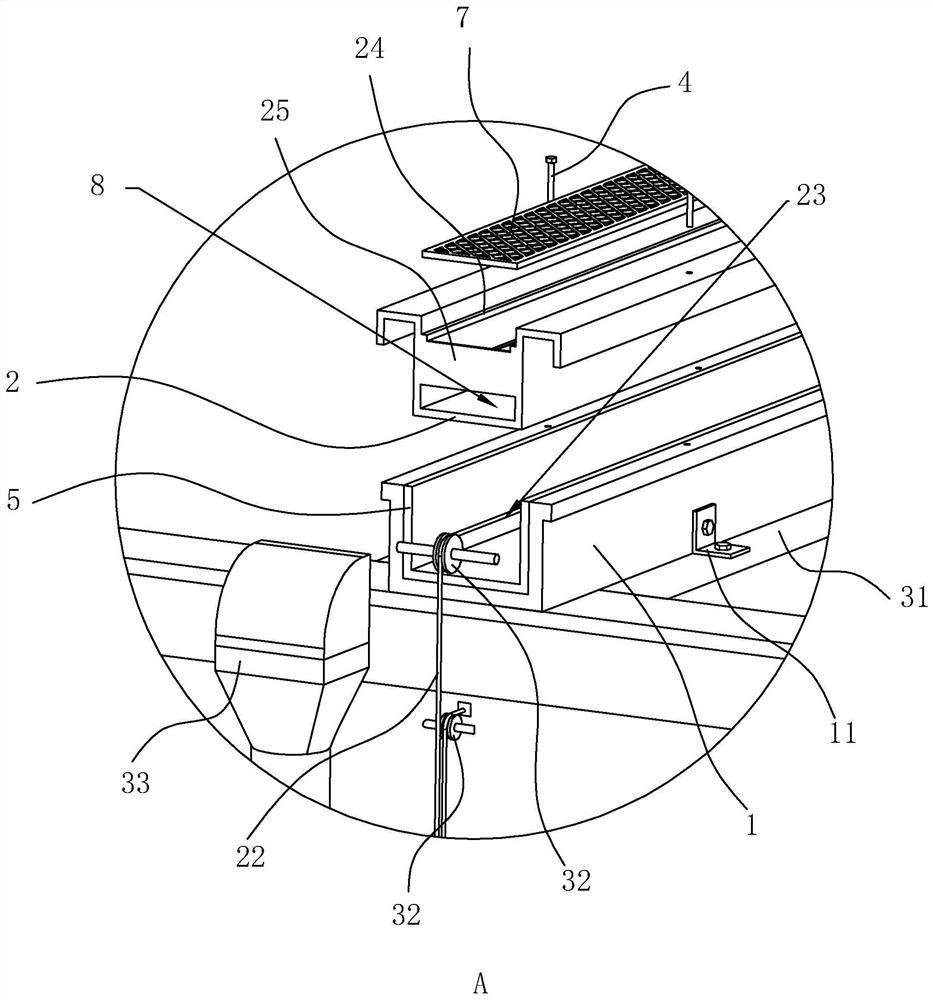

[0042] refer to figure 2 and image 3 , This kind of roof gutter includes a base 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com