Connecting structure and construction method of steel ribs and hoops of steel rib concrete structure column

A steel-reinforced concrete and connection structure technology, applied in the direction of structural elements, columns, pier columns, etc., can solve the problems of long construction time, increase the difficulty of construction work for construction personnel, and high labor intensity, so as to improve construction quality and avoid welding quality problem, overall good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

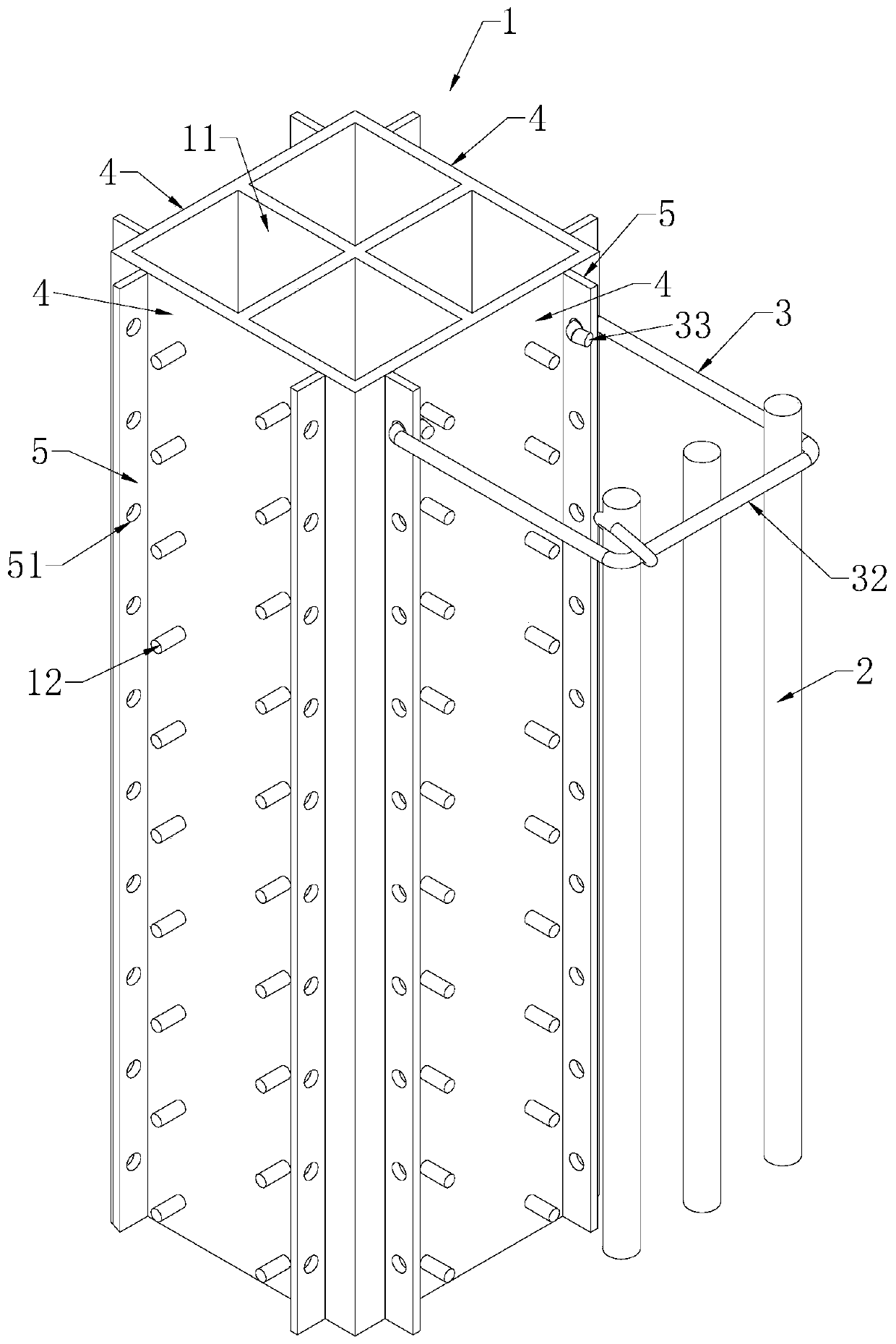

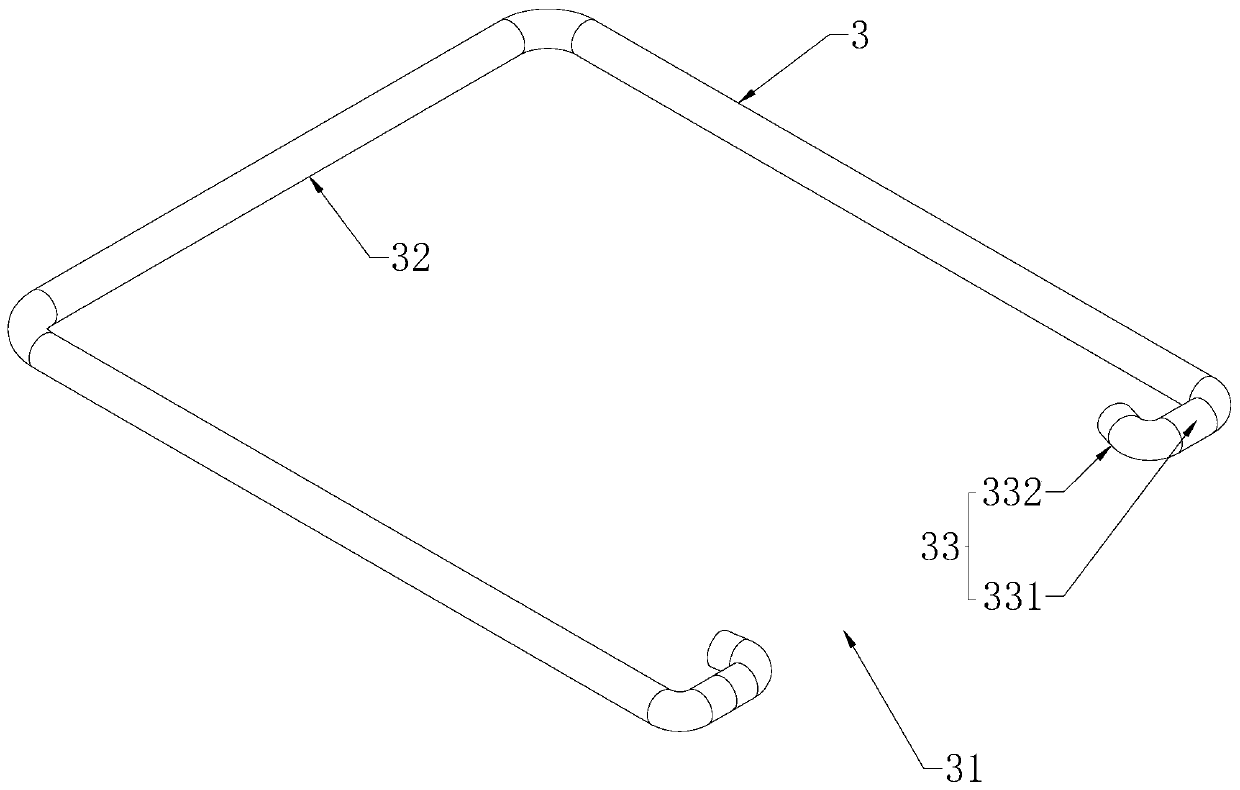

[0040] combine figure 1 and figure 2 As shown, a steel concrete structural column and stirrup connection structure includes a vertical welded and fixed steel frame column 1, and a number of longitudinal steel bars 2 are arranged and fixed on the peripheral side of the steel frame column 1 according to the design requirements, and the steel frame A stirrup 3 is connected between the steel bone column 1 and the longitudinal steel bar 2 . In this embodiment, the shaped steel column 1 is set as a box-shaped steel, and the box-shaped steel includes four first webs 4 that are vertically arranged and welded into a longitudinally extending box structure, and the inside of the box-shaped steel Welding has the cross-shaped framework 11 that plays a reinforcing role. The first web 4 is welded with a stirrup connecting plate 5 at the left and right symmetrical positions along its width direction, and the stirrup connecting plate 5 is welded and fixed on the outer surface of the first w...

Embodiment 2

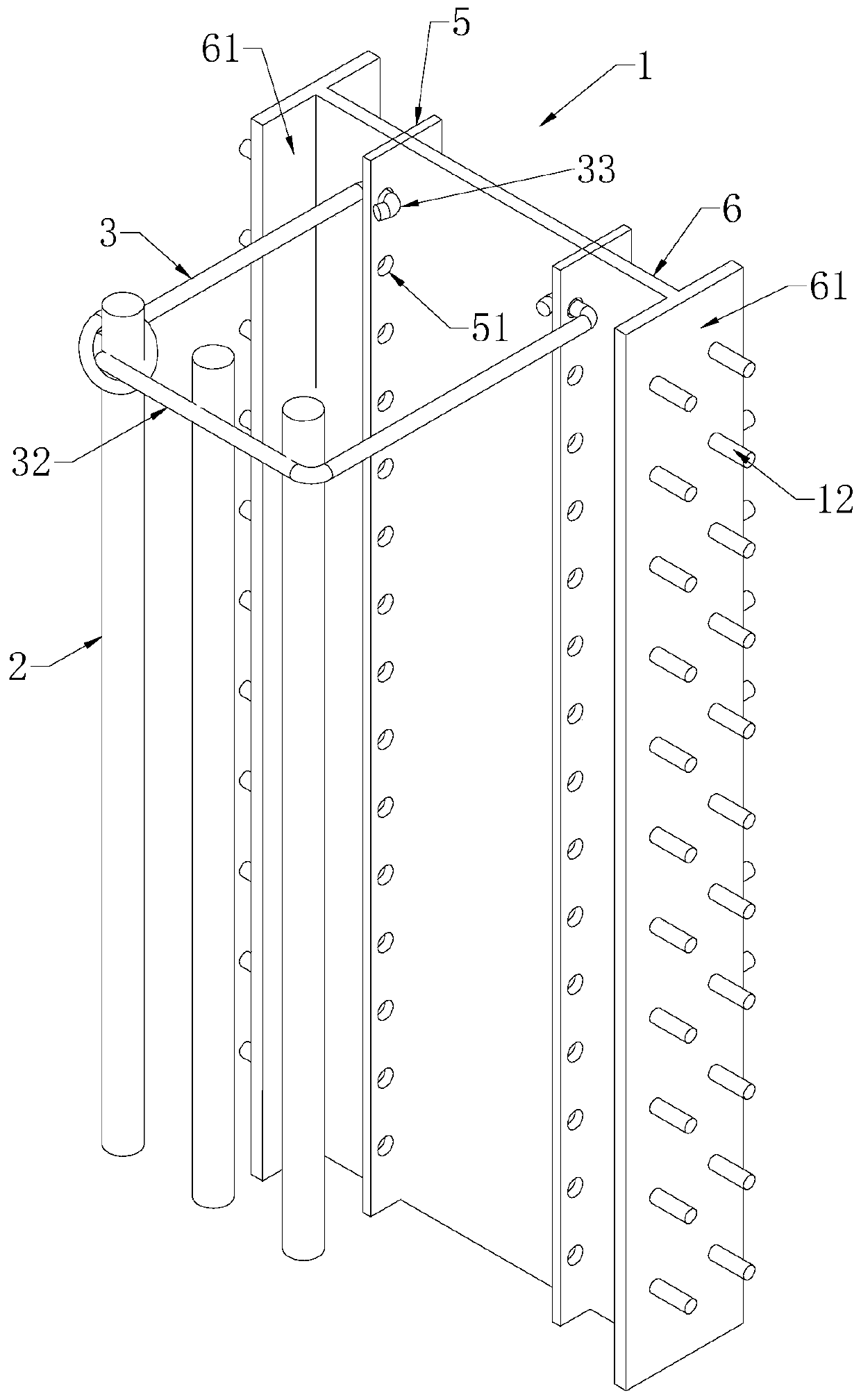

[0045] Such as image 3 As shown, a steel concrete structural column and stirrup connection structure, the difference from the first embodiment is: in this embodiment, the steel column 1 of the H-shaped steel is used; the H-shaped steel includes a second web 6 , both ends of the second web 6 are integrally formed or welded and fixed with a first end plate 61, and the first end plate 61 is perpendicular to the second web 6; on the side. The stirrup connecting plate 5 is welded and fixed on the two outer surfaces of the second web 6 , and the stirrup connecting plate 5 is welded and fixed on any one of the outer surfaces of the second web 6 along the position of one-third of its width direction .

Embodiment 3

[0047] Such as Figure 4 As shown, a steel concrete structural column and stirrup connection structure, the difference from Embodiment 1 is that: in this embodiment, the cross-shaped steel steel column 1 is used; the cross-shaped steel includes a cross-shaped structure The third web 7 can be formed by welding four third webs 7, or can be integrally formed to form a cross-shaped structure with four third webs 7, and the stirrup connecting plate 5 is welded and fixed to the third web 7. On the outer side of the three webs 7. The four ends of the cross-shaped structure formed by the third web 7 are welded and fixed with the second end plate 71, and the second end plate 71 is arranged perpendicular to the third web 7; the reinforcing nail 12 is welded and fixed on the second end plate 71 on the outer side.

[0048] The four third webs 7 are coplanar in pairs; the stirrup connecting plate 5 on a set of coplanar third webs 7 is set as the first stirrup connection group, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com