Electric soldering equipment based on automotive electronic components

A technology of electronic components and automobiles, which is applied in the field of electric soldering equipment processing, can solve the problems of reducing the use effect, not having an auxiliary heat dissipation structure, and electric soldering equipment does not have multiple limit structures, so as to shorten the time and improve the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

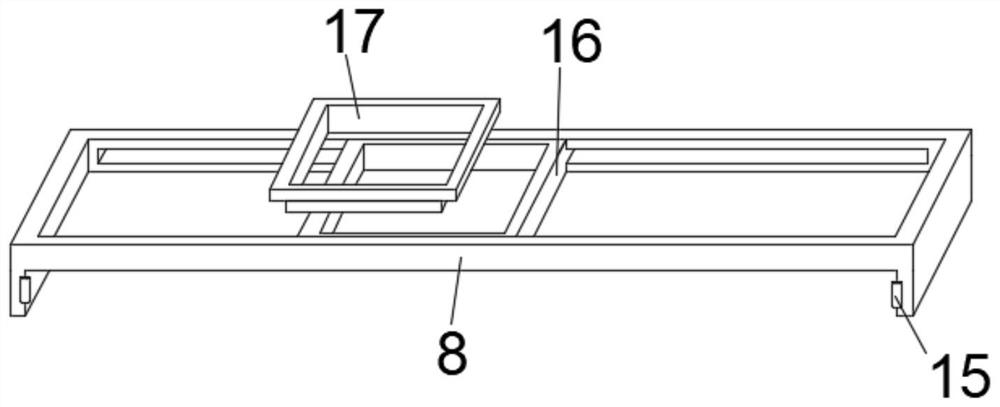

[0036] The middle of the sliding frame 16 is a rectangular hollow structure, the positioning carriage 8 and the sliding frame 16 are movably connected through the sliding slot, and the sliding frame 16 and the combination frame 17 are butted through the slot. When the electric soldering equipment is used, it can be used. According to the installation position of the electronic components, the sliding frame 16 is pushed on the inner side of the positioning carriage 8 by the chute, so that the installation positions of the sliding frame 16 and the electronic components are consistent, and the combination frame 17 of different sizes can be replaced according to the size of the electronic components. .

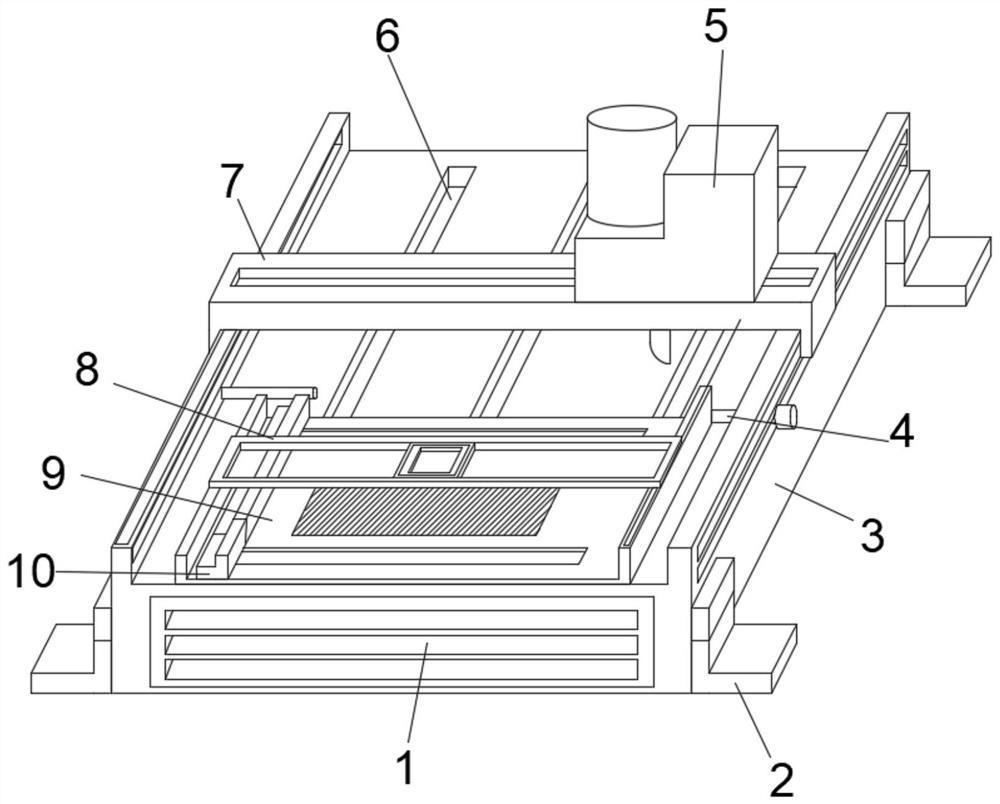

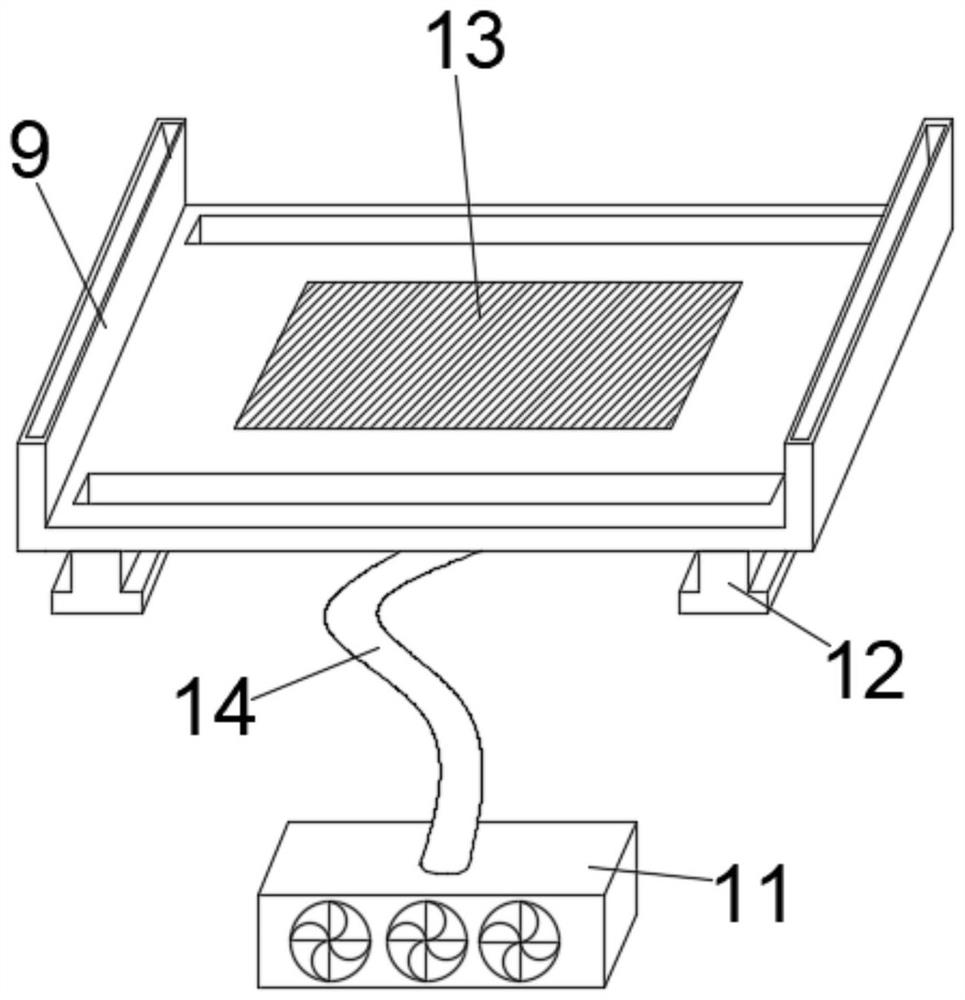

[0037] The upper end of the fixed base 3 is provided with three groups of push-pull grooves 6 side by side, and the bottom of the fixed card plate 9 is installed with two sets of limit card angles 12 that are docked with the push-pull grooves 6 . The setting can avoid the phenomen...

Embodiment 2

[0040] Both ends of the positioning carriage 8 are provided with sliding clamping wheels 15 , the inner side of the fixed clamping plate 9 is provided with a chute for docking the sliding clamping wheels 15 , and the upper outer surface of the fixed clamping plate 9 is movably installed with a fastening clamping plate 10 . When the electronic components on the circuit board are processed by electric soldering, the setting of the fastening card plate 10 can be used to fix the side of the circuit board to prevent the circuit board from loosening and falling off. At the same time, the setting of the sliding card wheel 15 can make the positioning The moving operation of the carriage 8 is smoother.

[0041] The fixed base 3 and the limit clamping rod 4 are butted by the chute, the outer surface of the limit clamping rod 4 is fixedly installed with a positioning socket 19, and one end of the limit clamping rod 4 is movably installed with a threaded sleeve rod 18, When the equipment ...

Embodiment 3

[0043] Two sets of lifting clips 2 are installed on both outer surfaces of the fixed base 3 , the fixed base 3 and the lifting clips 2 are connected and fixed by a fixing buckle 21 , and a telescopic sleeve 20 is movably installed on the inner side of the lifting clips 2 . The setting of the telescopic sleeve plate 20 can adjust the use length of the lifting clip 2, so as to play a balance adjustment effect on the placement of the electric soldering equipment.

[0044] The bottom of the fastening card 10 is installed with a sliding button 22 for docking the fixing card 9, the side of the fastening card 10 is fixedly installed with a rubber strip, and the sliding button 22 includes an upper clamping plate and a lower clamping plate. Bolts are installed between the bolts, and by rotating the bolts, the upper clamp plate and the lower clamp plate can be clamped and fixed, so that the moved clamping plate 10 plays a fixed role.

[0045] The front end of the fixed base 3 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com