Semi-conductive rubber roller and preparation method thereof

A rubber roller and semi-conductive technology, applied in the field of rubber rollers, can solve the problems of small molecule vulcanization aid precipitation pollution, poor imaging of printed products, environmental pollution, etc., to achieve poor imaging of printed products, less environmental pollution, and high product purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

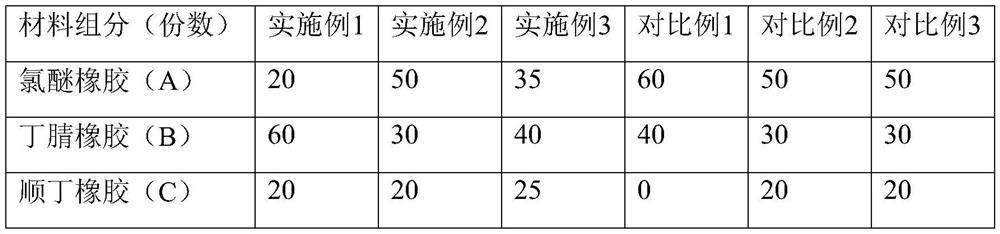

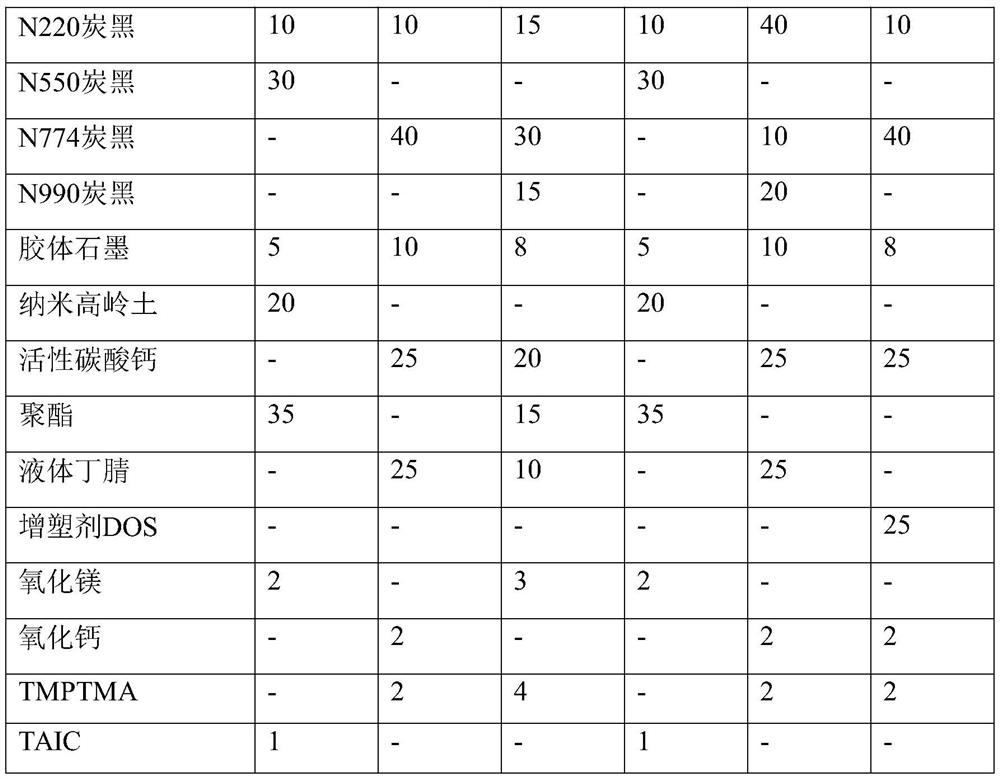

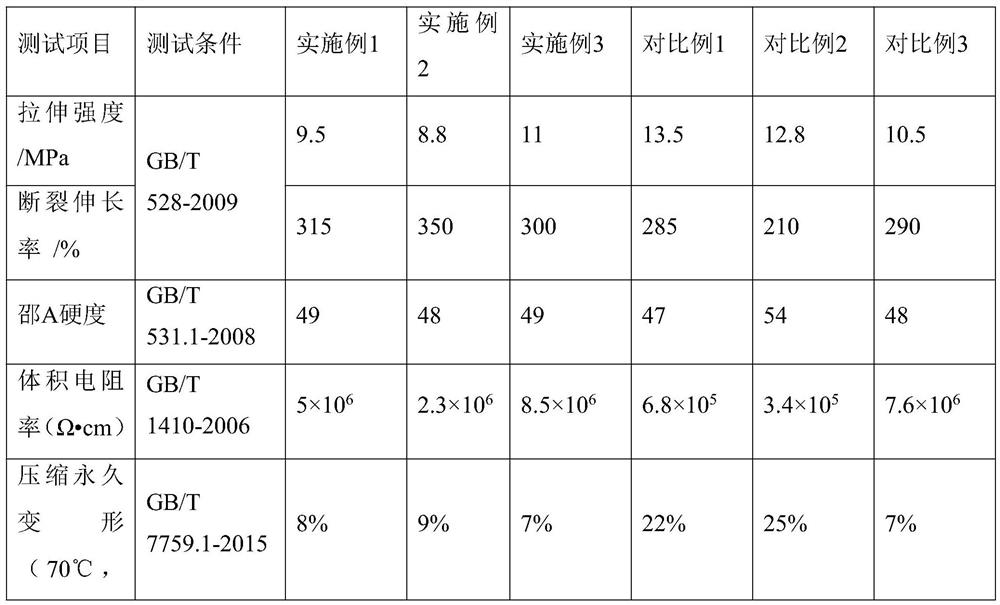

Embodiment 1

[0035] Raw materials were prepared according to the components of Example 1 shown in Table 1. Put the three rubber components A, B, and C in an internal mixer at 80°C, knead for 1 min, add carbon black N220, N550, and add nano-kaolin, magnesium oxide, colloidal graphite, and polyester in sequence after kneading for 3 min. , TAIC and other components, knead for 5 minutes to make it evenly mixed with the rubber compound, and the debinding temperature is 135°C. Add the mixed rubber after internal mixing to the rubber milling equipment, and pass through it three times to obtain a continuous rubber sheet with a thickness of 5 mm, and cool it to room temperature for 2 hours.

[0036] Put the cold rubber sheet into the rubber extruder and extrude it continuously into a hollow rubber tube (outer diameter 15mm, inner diameter 6mm), and set the temperature of each section of the screw to 50°C. The rubber hose is air-cooled, pulled by a tractor, and enters the beam of the electron accel...

Embodiment 2

[0039]Raw materials were prepared according to the composition of Example 2 shown in Table 1. Put the three rubber components A, B, and C in an internal mixer at 70°C, knead for 2 minutes, add carbon black N220 and N774, and add calcium carbonate, calcium oxide, colloidal graphite, and liquid butyl in sequence after kneading for 4 minutes. Nitrile, TMPTMA and other components were mixed for 5 minutes to make them evenly mixed with the rubber compound, and the debinding temperature was 138°C. Add the mixed rubber after internal mixing to the rubber milling equipment, and pass through it three times to obtain a continuous rubber sheet with a thickness of 5 mm, and cool it to room temperature for 2 hours.

[0040] Put the cold rubber sheet into the rubber extruder and extrude it continuously into a hollow rubber tube (outer diameter 15mm, inner diameter 6mm), and set the temperature of each section of the screw to 45°C. The rubber hose is air-cooled, pulled by a tractor, and ent...

Embodiment 3

[0043] Raw materials were prepared according to the composition of Example 3 shown in Table 1. Put the three rubber components A, B, and C in an internal mixer at 60°C, knead for 1 min, add carbon black N220, N774, N990, and add calcium carbonate, magnesium oxide, colloidal graphite, and Polyester, liquid nitrile, TMPTMA and other components were kneaded for 5 minutes to make them evenly mixed with the rubber material, and the debinding temperature was 135°C. Add the mixed rubber after banbury mixing to the rubber milling equipment, and pass through it three times to obtain a continuous rubber sheet with a thickness of 8 mm, and cool it down to room temperature for 3 hours.

[0044] Put the cold rubber sheet into the rubber extruder and extrude it continuously into a hollow rubber tube (outer diameter 15mm, inner diameter 6mm), and set the temperature of each section of the screw to 40°C. The rubber hose is air-cooled, pulled by a tractor, and enters the beam of the electron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com