Mechanical automatic feeding device and feeding method thereof

An automatic feeding, mechanical technology, applied in metal processing and other directions, can solve the problems of assembly difficulty, complex structure, collision, etc., and achieve the effect of reducing assembly difficulty, simplifying equipment structure, and running smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The following is attached Figure 1-13 The application is described in further detail.

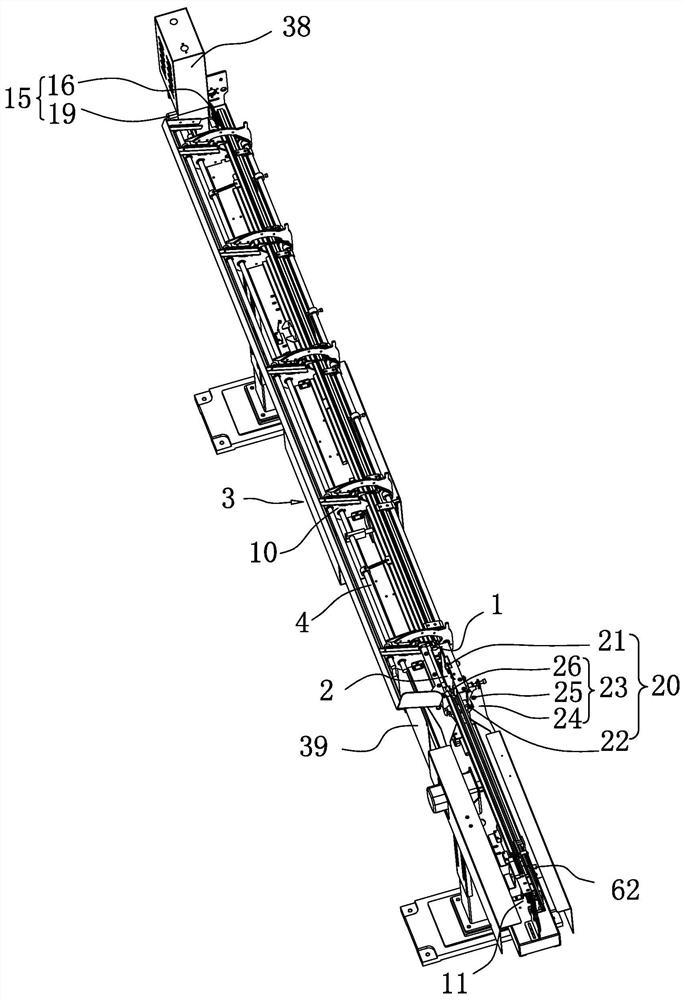

[0082] refer to figure 1 , a mechanical automatic feeding device, comprising:

[0083] The stock trough 1 is used as a conveying channel for rods, and one end of the stock trough 1 is connected with a residual material collection trough 2 . The bottom of the residual material collection tank 2 communicates with a storage box 39 to increase the amount of residual material that can be accommodated.

[0084] The feeding mechanism 3 is used to transfer the rods to the feeding tank 1.

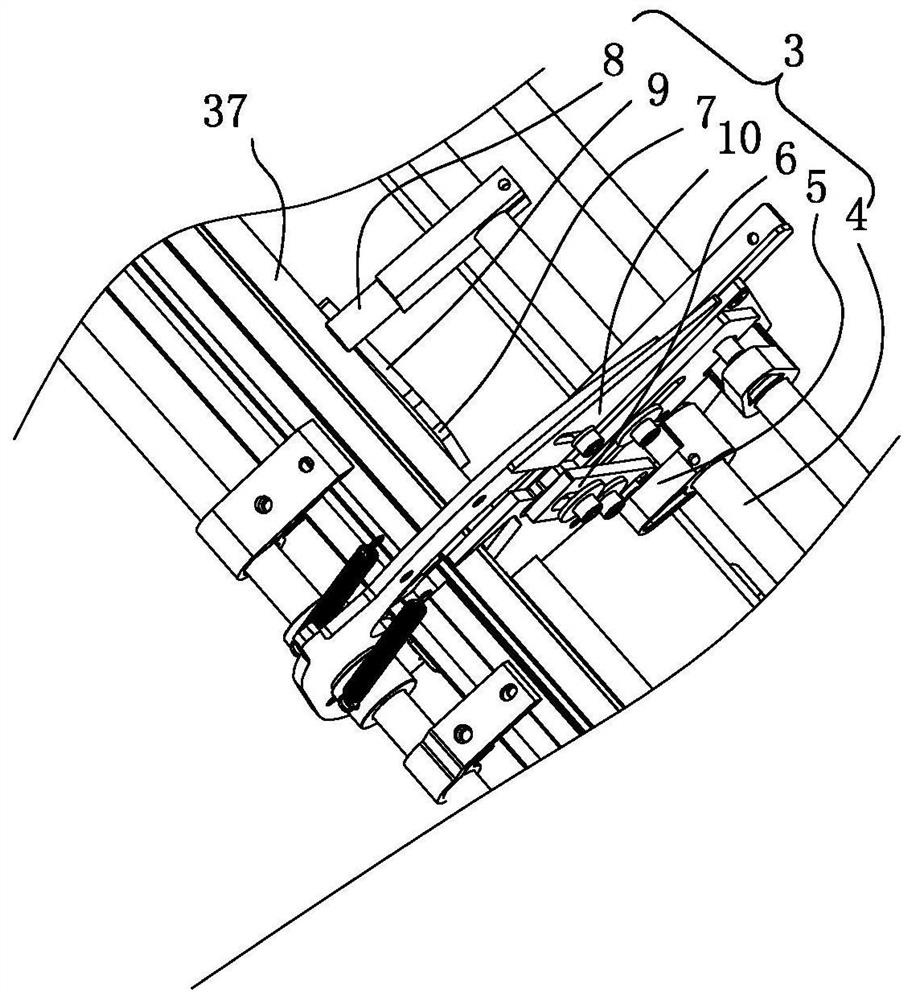

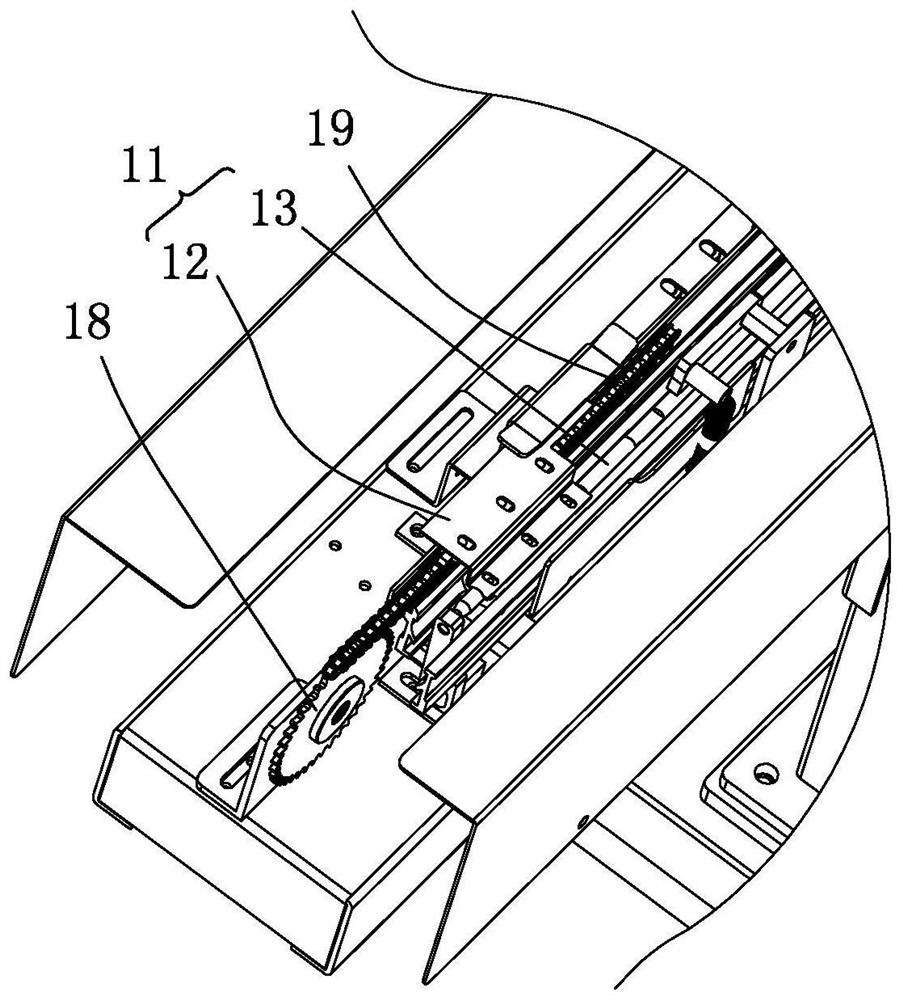

[0085] As one implementation, see figure 1 and figure 2 , the feed mechanism 3 includes a support bracket 10, a feed rotating rod 4, a feed dial 5, a feed push block 6, a feed top block 7 and a feed rotary top piece 8, and the feed top block 7 is provided with a feeding Material missing corner 9, feeding top block 7 is arranged on the discharge end of the support bracket 10, the discharge end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com