Stock garbage screening and reduction treatment system and method

A treatment system and treatment method technology, which is applied in the field of screening and reduction treatment system for stock garbage, can solve the problems of poor sales of light materials, overflowing odor, and difficulty in achieving the expected screening effect, so as to avoid personnel methane Risk of poisoning, speed up the air flow, and avoid the effects of poor exit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

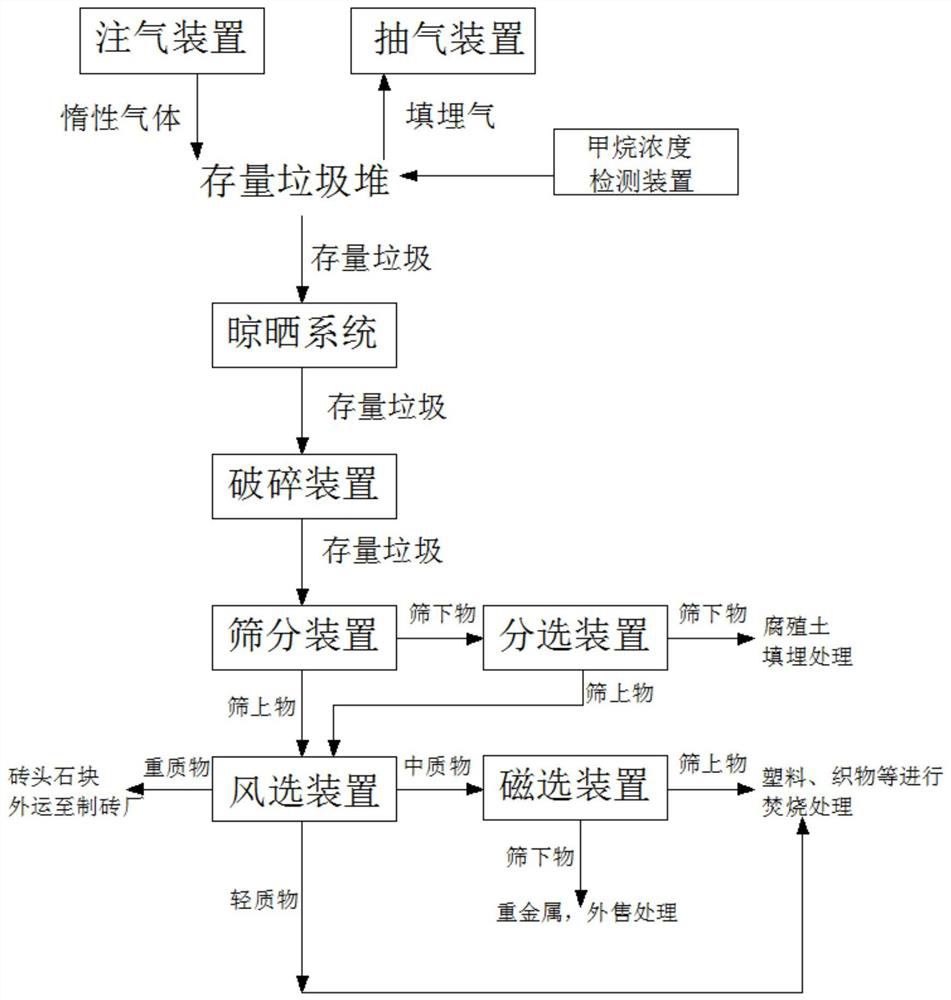

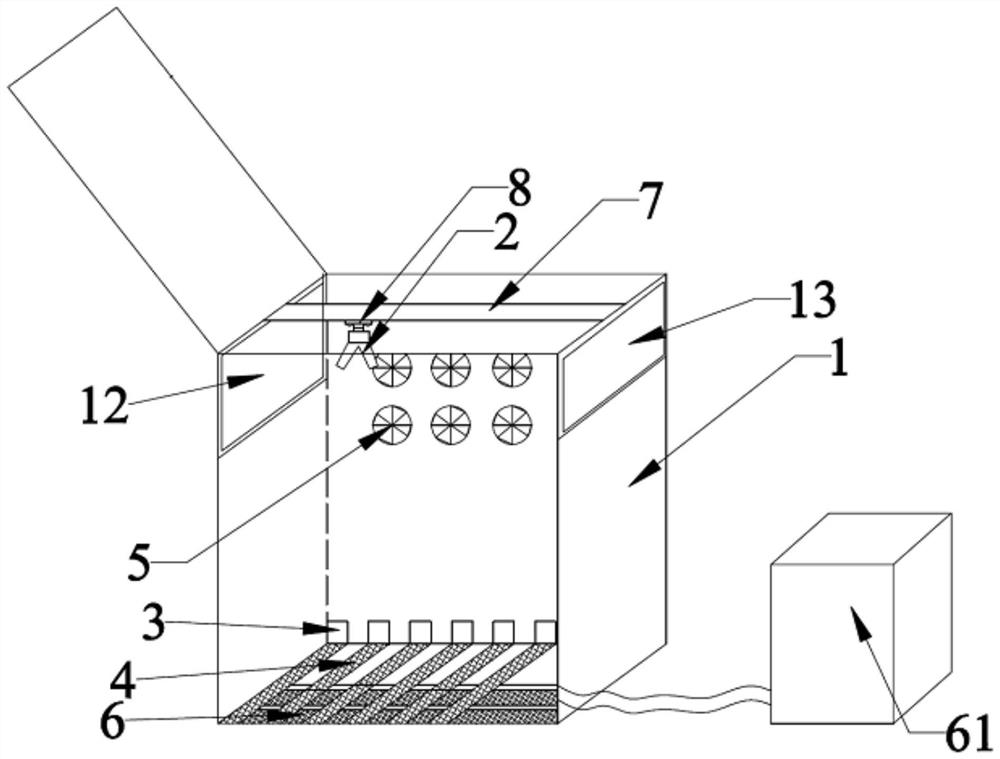

[0038] Such as figure 1As shown, a screening and reducing treatment system for stock garbage, including gas injection device, air extraction device, methane concentration detection device, drying system, crushing device, screening device, sorting device, wind separation device, magnetic separation device and leachate collection device; the gas injection device is connected to the stock garbage dump and used to inject inert gas into the stock garbage dump; The storage garbage dump is connected and used to detect the methane concentration in the storage garbage dump; the drying system is used to reduce the water content of the storage garbage; the leachate outlet of the drying system, the leachate outlet of the screening device, and the leachate of the sorting device The outlets are respectively connected with the leachate collection device;

[0039] The stock garbage outlet of the drying system is connected to the stock garbage inlet of the crushing device, and the stock garba...

Embodiment 2

[0049] A screening and reducing treatment system for stock garbage, including an air injection device, an air extraction device, a methane concentration detection device, a drying system, a crushing device, a vibrating hopper, a screening device, a sorting device, a wind separation device, and a magnetic separation device and leachate collection device; the gas injection device is connected to the stock garbage dump and used to inject inert gas into the stock garbage dump; The storage garbage dump is connected and used to detect the methane concentration in the storage garbage dump; the drying system is used to reduce the water content of the storage garbage; the leachate outlet of the drying system, the leachate outlet of the screening device, and the leachate of the sorting device The outlets are respectively connected to leachate collection devices; wherein, the screening device is a drum screen, and the sorting device is a disc sorter. The vibrating hopper is set between t...

Embodiment 3

[0064] A screening and reducing treatment system for stock garbage, comprising an air injection device, an air extraction device, a methane concentration detection device, a drying system, a crushing device, a screening device, a sorting device, a wind separation device, a magnetic separation device and a leaching device. liquid collection device; the gas injection device is connected to the stock garbage dump and used to inject inert gas into the stock garbage dump, the gas extraction device is connected to the stock garbage dump and used to extract the landfill gas in the stock garbage dump, the methane concentration detection device is connected to the stock garbage dump It is connected and used to detect the methane concentration in the stock garbage dump; the drying system is used to reduce the water content of the stock garbage; the leachate outlet of the drying system, the leachate outlet of the screening device, and the leachate outlet of the sorting device are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com