Nethod for driving mining device

A technology for equipment and control equipment, which is applied in mining equipment, mining equipment, earth-moving drilling, etc., and can solve problems such as inability to detect gas concentration, improper operation of gas sensors, and gas sensor failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

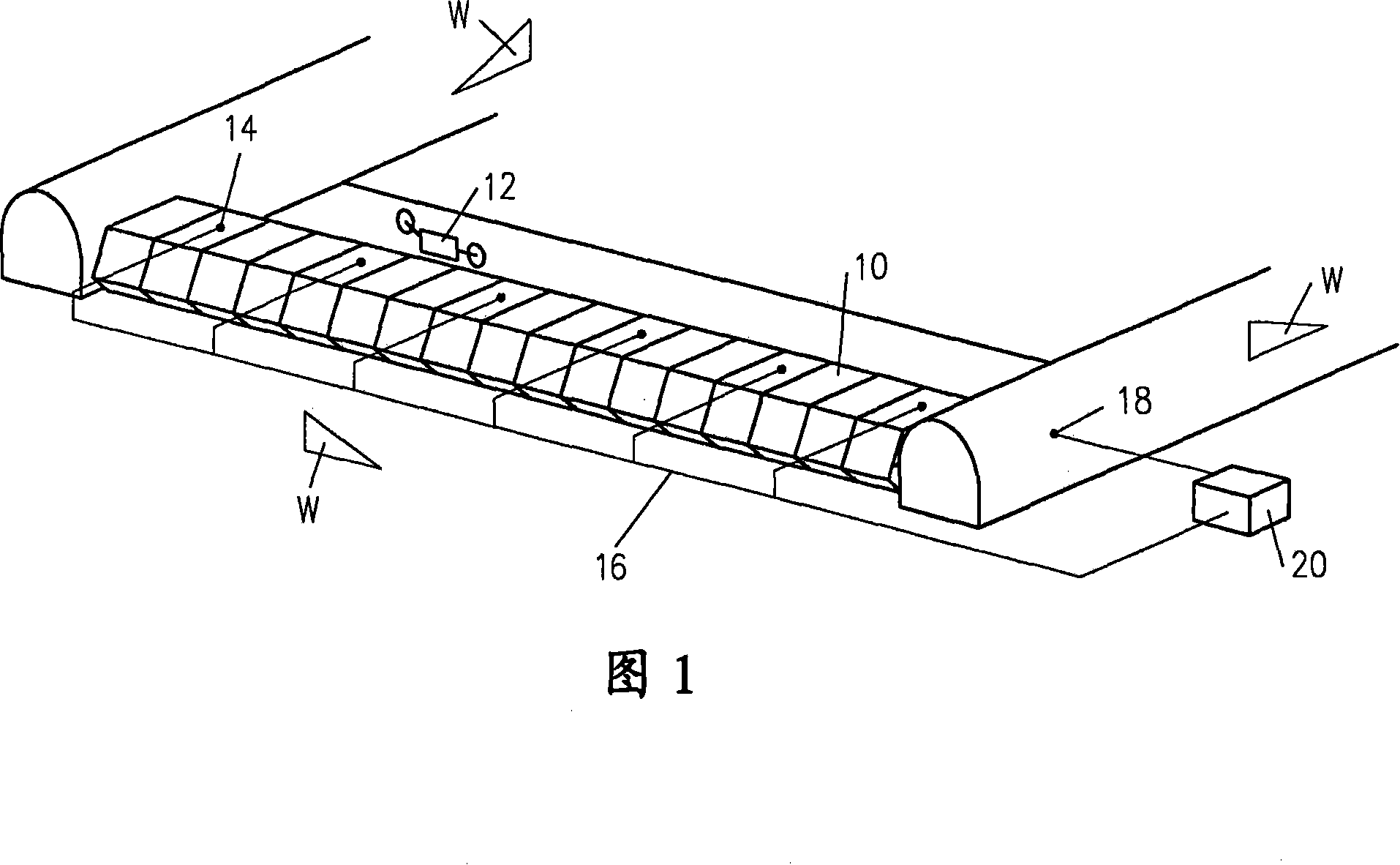

[0027] FIG. 1 shows a greatly simplified schematic diagram of a face support with a plurality of mining locations 10 arranged next to each other, which are connected in the usual manner to a conveyor (not shown). Reference numeral 12 denotes a mining device, which can be designed as a rolling mill (Walze) or a coal plow (Hobel). The ventilation direction is indicated in the diagram by arrow W, which means that the air flow moves counterclockwise in diagram 1 .

[0028] In order to measure the methane concentration occurring within the path, methane sensors 14 are provided along the face, for example in every tenth production location, which are connected via a common bus 16 to a control device 20 . In this case, the bus 16 can be a data bus with which the control devices of the individual mining locations 10 communicate with each other. Furthermore, a further methane sensor 18 is arranged at the end of the working face. The gas sensors 14 can be individually controlled or in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com