Quantitative feeding device for metal coating research and development

A metal coating and feeding device technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of inconvenient quick installation of device parts, inconvenient device classification and feeding, inconvenient quantitative parts replacement, etc., to achieve increased variety Enhanced performance, increased usability, and enhanced sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

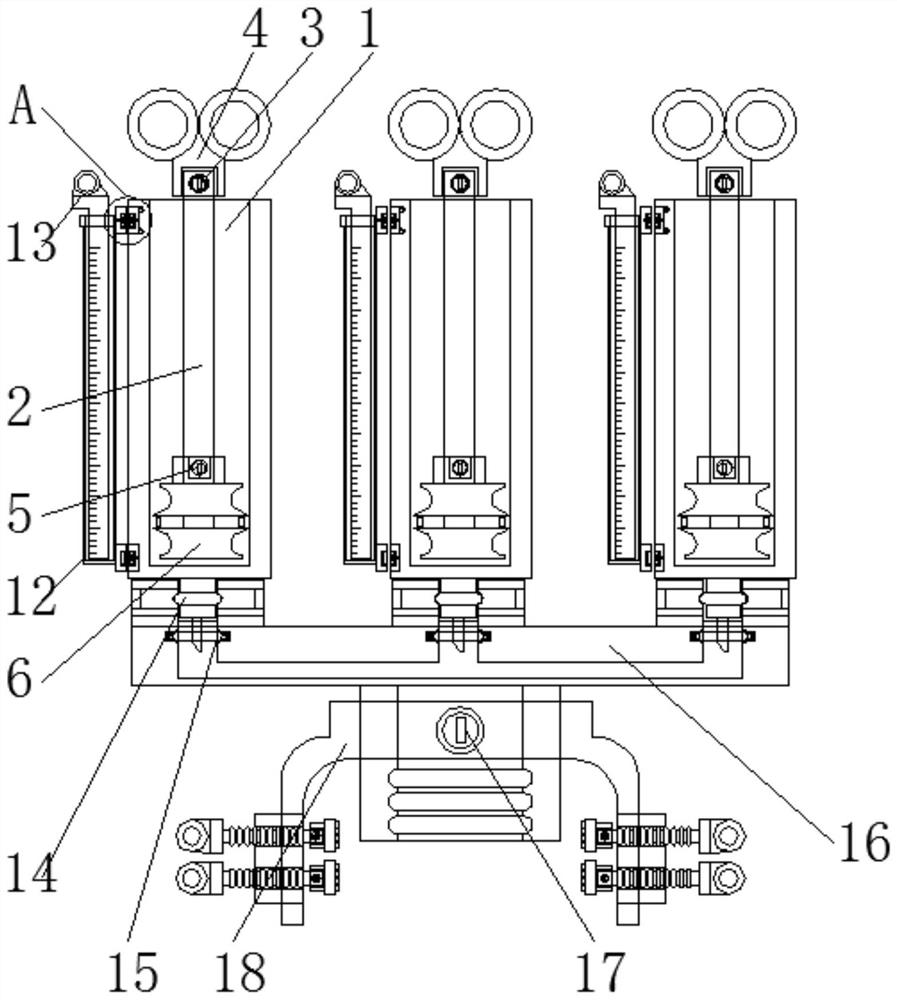

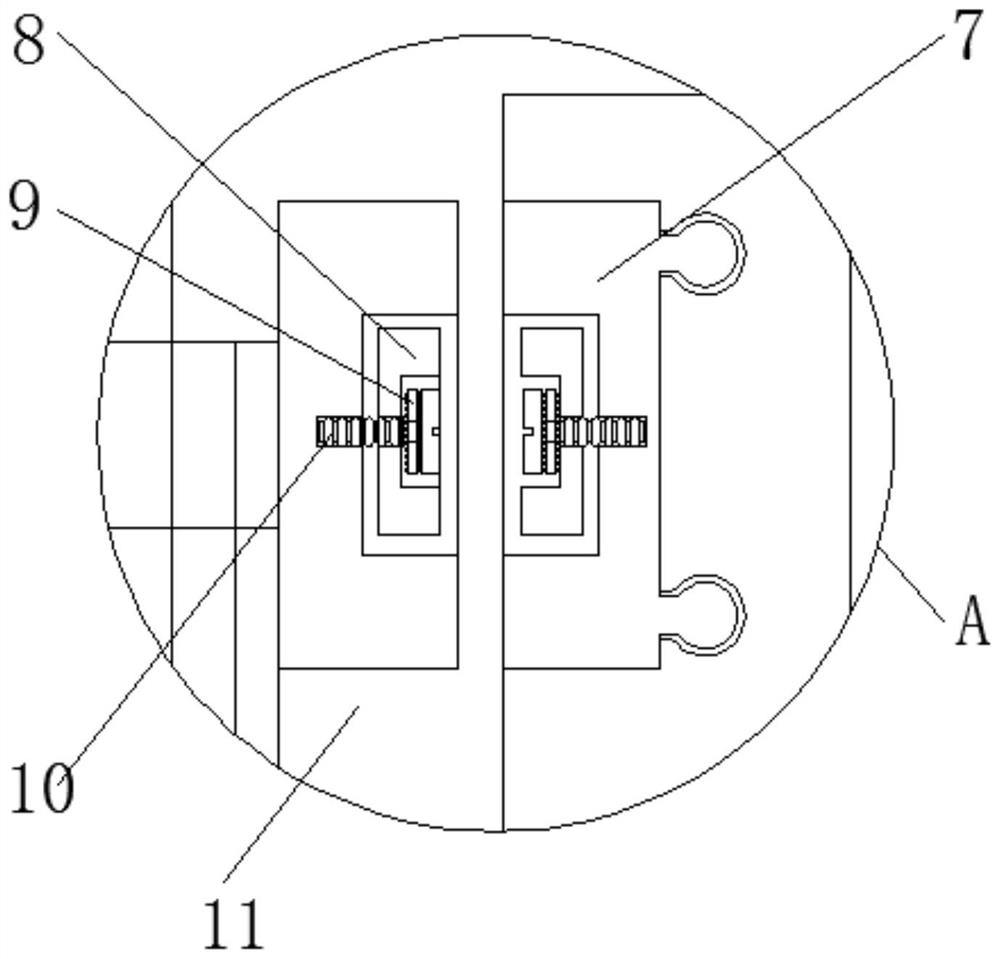

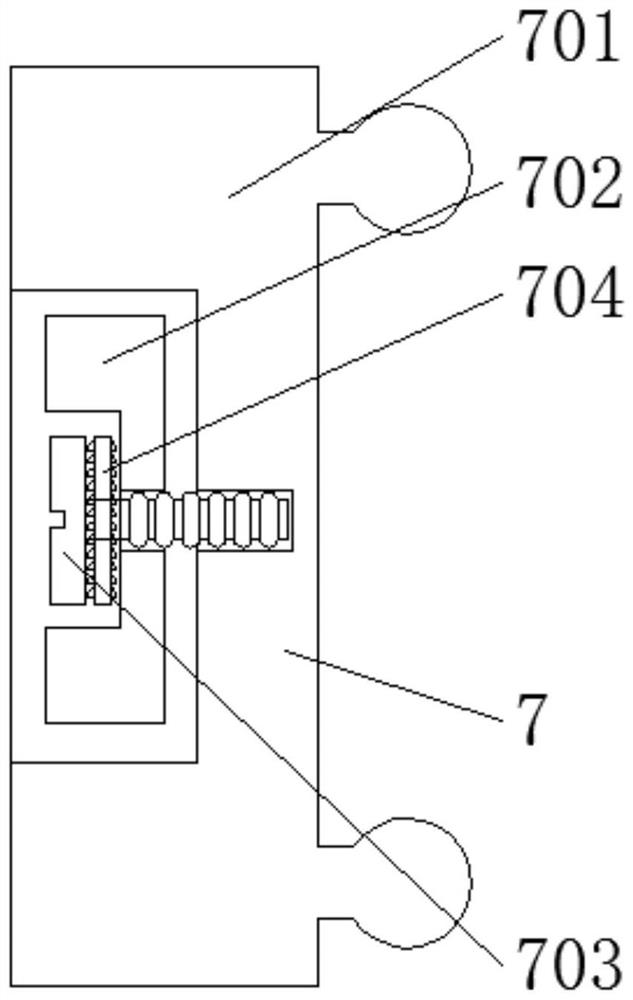

[0033] see Figure 1-5 , in this embodiment: a quantitative feeding device for metal coating research and development, including an injection tube 1, an injection rod 2 is installed inside the injection tube 1, and a first fixing rod 3 is installed at one end of the injection rod 2, and the first fixed The outer wall of the rod 3 is screwed with a pressing sleeve 4, the other end of the injection rod 2 is screwed with a second fixing rod 5, and the outer wall of the second fixing rod 5 is screwed with a rubber block 6, and one side of the injection tube 1 is installed with a magnetic The suction mechanism 7 is provided with an iron sheet 8 on one side of the magnetic attraction mechanism 7, a fixing sheet 9 is mounted on the inner wall of the iron sheet 8, and the inner wall of the fixing sheet 9 is screwed with a third fixing rod 10. The outer wall is screwed with a connecting block 11, and one side of the connecting block 11 is provided with a connecting sleeve 12, the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com