Relay test jig

A technology for testing jigs and jigs, applied in the field of jigs, can solve problems such as non-slip of inconvenient devices, long debugging time, and increased false detection rate, so as to increase usability and solve the effects of inaccurate alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

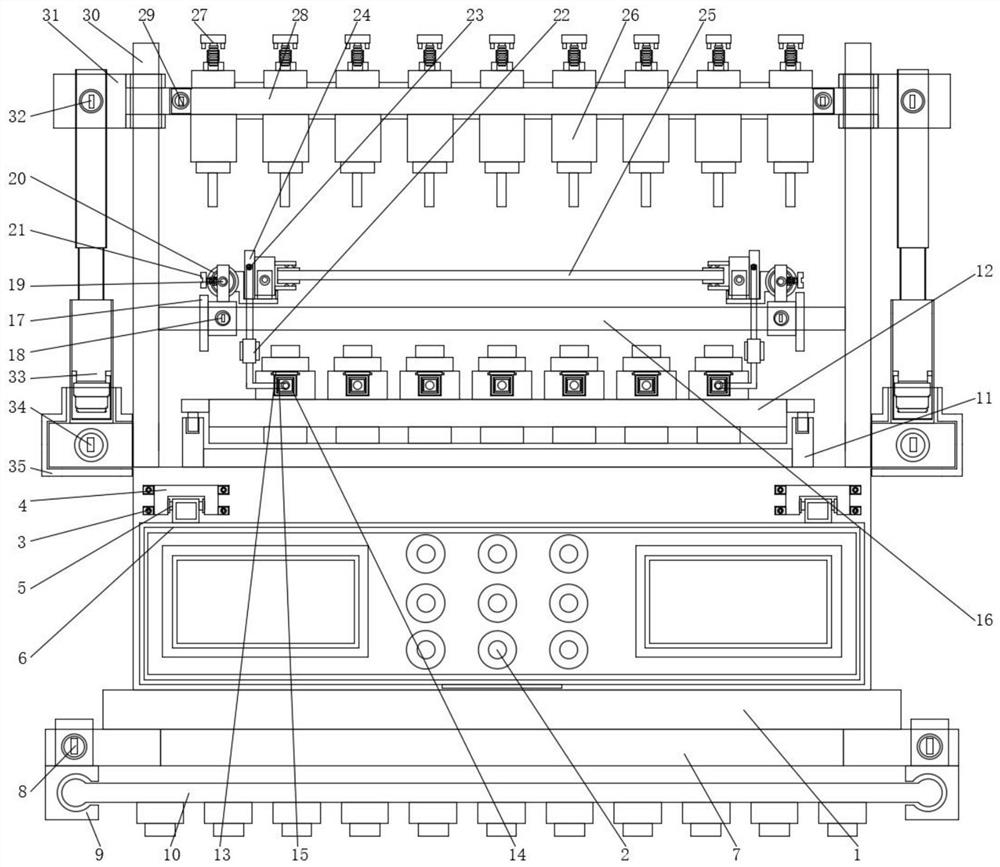

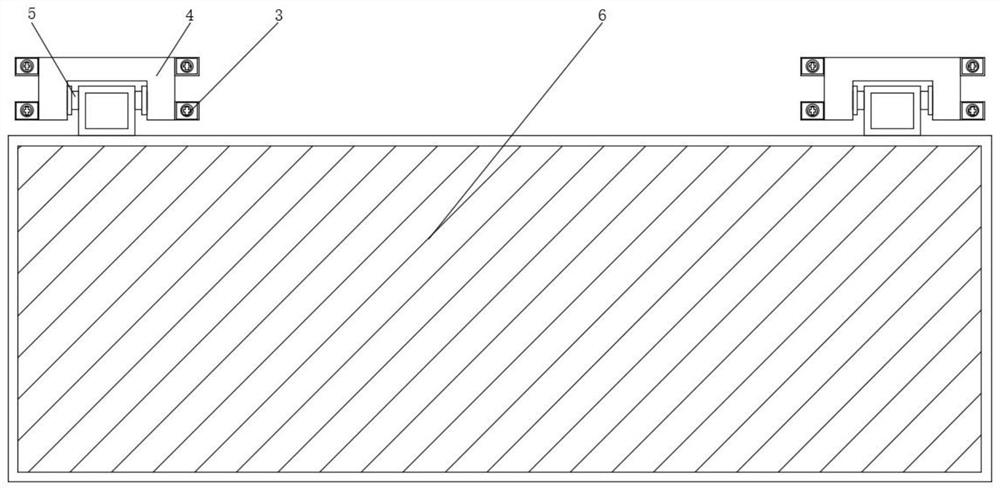

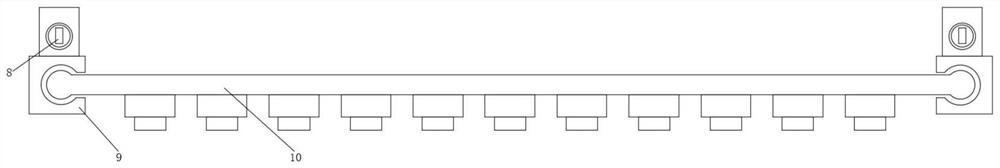

[0030] see Figure 1-6 , in this embodiment: a relay test fixture, including a fixture table 1 and a fixture reel 11, a control switch 2 is installed on the inside of the fixture table 1, and a first positioning rod is connected to the front of the control switch 2 3. The first connecting block 4 is connected to the outer side of the first positioning rod 3, and the first rotating shaft 5 is installed on the inner side of the first connecting block 4, and the protective cover 6 is arranged under the first rotating shaft 5, and the protective cover 6 A base 7 is installed, the two ends of the base 7 are connected with a second positioning rod 8, and the outside of the second positioning rod 8 is connected with a second connecting block 9, and the inner side of the second connecting block 9 is connected with a non-slip soft rubber strip 10 , the jig reel 11 is installed above the control switch 2, and the test lower mold 12 is installed above the jig reel 11, the front of the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com