Spherical cold-brewed green tea and processing technology thereof

A processing technology, green tea technology, applied in the field of spherical cold-brewed green tea and its processing technology, can solve the problems of short rolling time, only brewing with boiling water, too tight molding, etc., to achieve a tight and beautiful appearance, The effect of changing the tightness of the tea ball and changing the moisture regain method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of spherical cold-brewed green tea industrial processing technology:

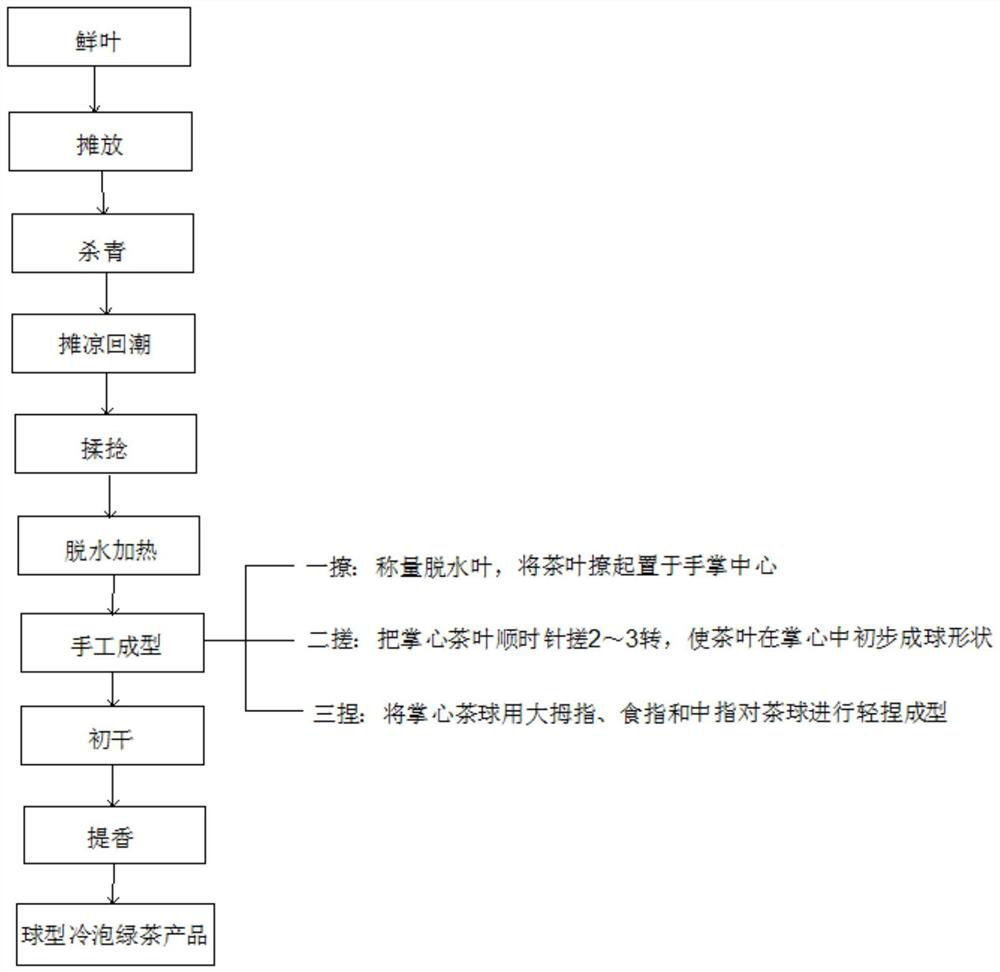

[0039] The technological process is: fresh leaves→spreading→cooking→spreading to cool and regain moisture→kneading→dehydration and heating→manual molding→primary drying→increasing fragrance→spherical cold-brewed green tea products. Such as figure 1 shown.

[0040] The production process in turn includes:

[0041] Step 1: picking fresh leaves with one bud and one leaf suitable for making green tea;

[0042] Step 2: spread the fresh leaves in the green tank for spreading, the thickness of the spreading is 5cm, the spreading time is 4h, the blast is blown once every 3h for 10min, and the weight loss of spreading is 6%;

[0043] Step 3: The greening process is carried out on the spread leaves, and the greening equipment is selected from the 80 type dry-heat roller greening machine and the hot air type greening machine. The water content of the above-mentioned green leaves is not less than 56%;...

Embodiment 2

[0054] A kind of spherical cold-brewed green tea industrial processing technology:

[0055] The technological process is: fresh leaves→spreading→cooking→spreading to cool and regain moisture→kneading→dehydration and heating→manual molding→primary drying→increasing fragrance→spherical cold-brewed green tea products. Such as figure 1 shown.

[0056] The production process in turn includes:

[0057] Step 1: picking fresh leaves with one bud and two leaves suitable for making green tea;

[0058] Step 2: spread the fresh leaves in the green tank for spreading, the thickness of the spreading is 10cm, the spreading time is 14h, and the air is blasted for 20min once every 2h, and the weight loss of spreading is 8%;

[0059] Step 3: De-enzyming the spread leaves. The de-enzyming equipment is 80-type dry-heat drum de-enzyming machine and hot-air type. The tea-inlet temperature of the de-enzyming machine is 280°C, the middle part is 360°C, and the tea outlet is 190°C. Leaf moisture c...

experiment example

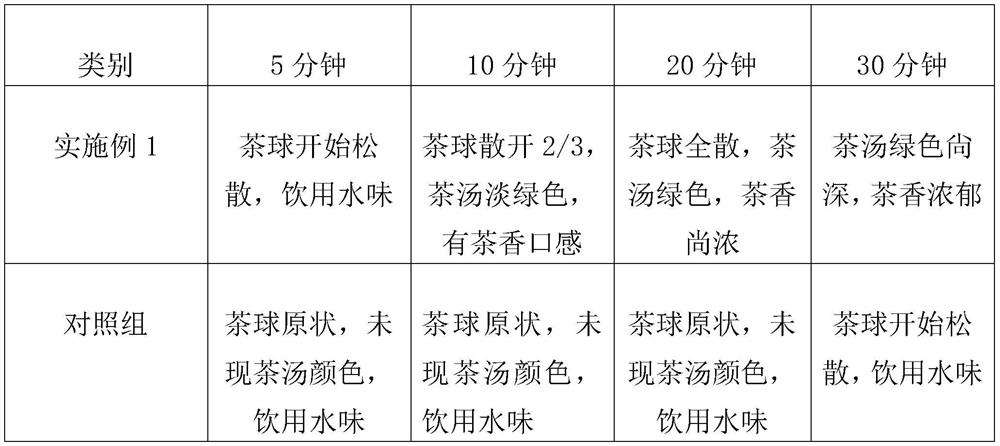

[0068] The product prepared in Example 1 was selected as the experimental group, and the commercially available spherical green tea was selected as the control group, and observations were carried out within the adaptation time respectively.

[0069] Experimental results:

[0070]

[0071] The cold-brewed tea prepared in Example 1 has short immersion time, fast ball loosening, high leaching rate after immersion, and good mouthfeel. In contrast, the tea balls of the control group did not disperse after soaking for 30 minutes, and the color and taste of the tea soup did not meet the requirements within the specified time.

[0072] The invention provides a processing technology of spherical cold-brewed green tea. In the technology, the moisture content of green leaves is about 56%, and the aroma is higher; the pressure-by-pressure and long-time kneading is adopted, and the finished tea has a tight and beautiful appearance and broken cells. The rate directly exceeds 80%; the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com