Composite microbial agent and production method thereof

A technology of composite microbial agent and microbial agent, applied in fertilizer mixture, fertilization device, application, etc., can solve problems affecting the survival of biological bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

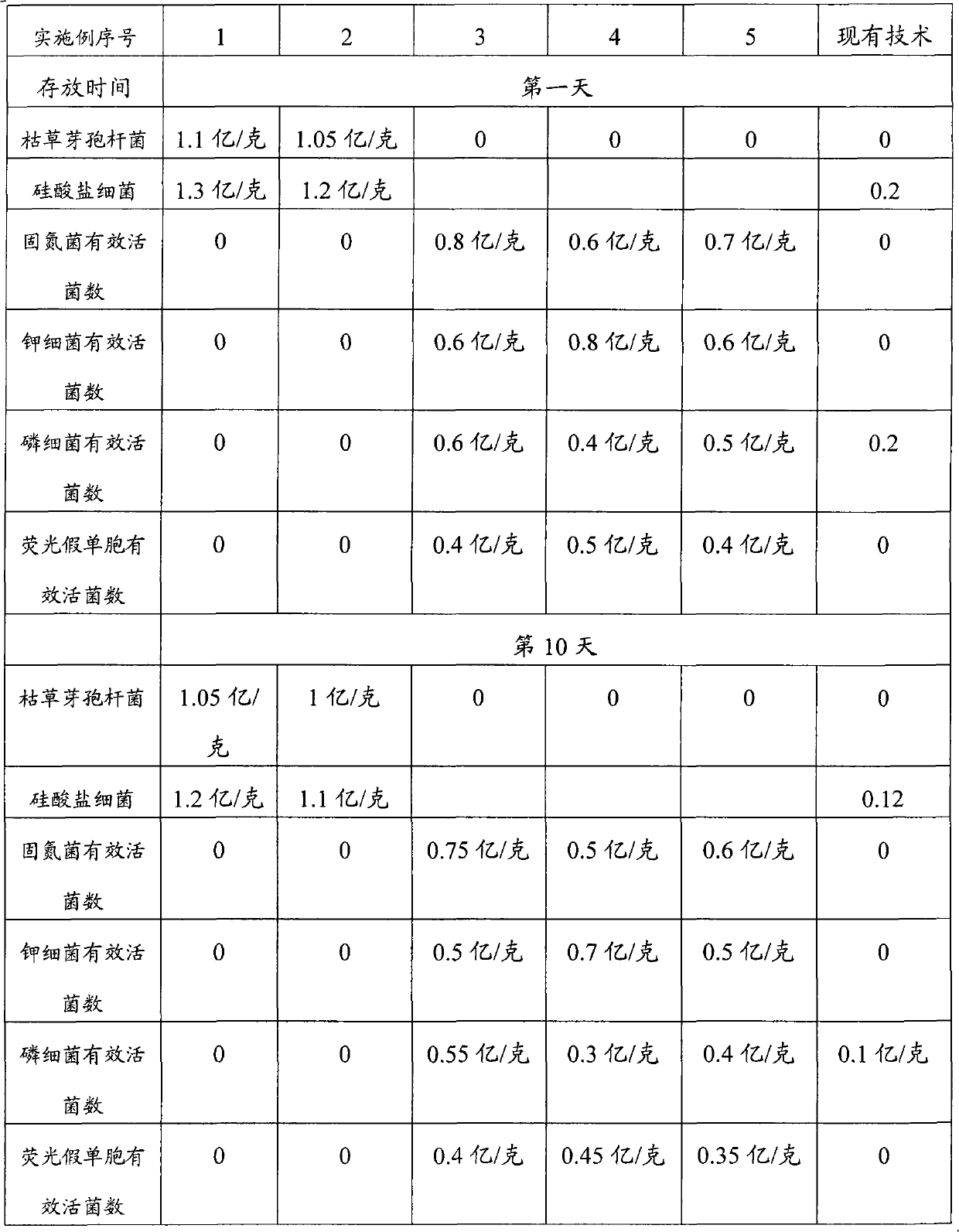

Examples

Embodiment 1

[0119] Embodiment 1: the production of composite microbial bacterial agent of the present invention.

[0120] The production steps of this embodiment are as follows:

[0121] A. Preparation of granular materials

[0122] Bentonite, peat soil, and lignite were pulverized to 50 mesh using a fertilizer pulverizer produced by Shandong Tancheng Zhenghua Machinery Factory. Then, weigh 45 parts by weight of bentonite, 30 parts by weight of peat soil, and 15 parts by weight of lignite and mix them evenly, pour them into a vertical mixer, and after fully stirring, put them on the belt conveyor continuously and evenly from the material door, and send them to Jiayi, Jingmen City. The JYZ3000 disc granulator produced by Machinery Co., Ltd., the speed of the disc granulator is controlled at 40rpm, and the inclination angle is controlled at 65 degrees. These materials are humidified, granulated, and grown in the disc granulator, and then The disc overflows to obtain granular material.

...

Embodiment 2

[0133] Embodiment 2: the production of composite microbial bacterial agent of the present invention.

[0134] The production steps of this embodiment are as follows:

[0135] A. Preparation of granular materials

[0136] Bentonite, peat soil, and lignite were pulverized to 100 mesh using a fertilizer pulverizer produced by Shandong Tancheng Zhenghua Machinery Factory. Then, weigh 65 parts by weight of bentonite, 10 parts by weight of peat soil, and 35 parts by weight of lignite and mix them evenly, pour them into a vertical mixer, and after fully stirring, put them on the belt conveyor continuously and evenly from the material door, and send them to Jiayi, Jingmen City. The JYZ3000 disc granulator produced by Machinery Co., Ltd., the speed of the disc granulator is controlled at 60rpm, and the inclination angle is controlled at 30 degrees. These materials are humidified, granulated, and grown in the disc granulator, and then The disc overflows to obtain granular material.

...

Embodiment 3

[0147] Embodiment 3: the production of composite microbial bacterial agent of the present invention.

[0148] The production steps of this embodiment are as follows:

[0149] A. Preparation of granular materials

[0150] Weigh 22 parts by weight of urea, 13.25 parts by weight of ammonium phosphate, and 8.5 parts by weight of potassium chloride, mix them evenly, pour them into a vertical mixer, and after fully stirring, put them into the belt conveyor continuously and evenly from the material door, and send them to Jiayi, Jingmen City The JYZ3000 disc granulator produced by Machinery Co., Ltd., the speed of the disc granulator is controlled at 50rpm, and the inclination angle is controlled at 55 degrees. These materials are humidified, granulated, and grown in the disc granulator, and then The disc overflows to obtain granular material.

[0151] B. Drying and screening

[0152] The granular material obtained in step A) is sent to the drying drum drying drum produced by Zheng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com