Hollow glass processing method

A processing method and glass technology, applied in the direction of transparent/reflective heating device, sustainable building, window/door improvement, etc., can solve the problems of long-term retention of inert gas, poor sealing of hollow glass doors, poor energy-saving effect of glass doors, etc. , to achieve long-term stable size, high reliability, and maintain the effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the examples.

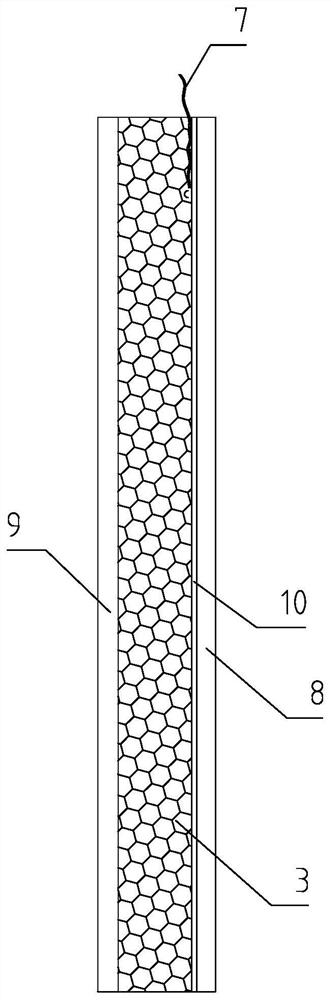

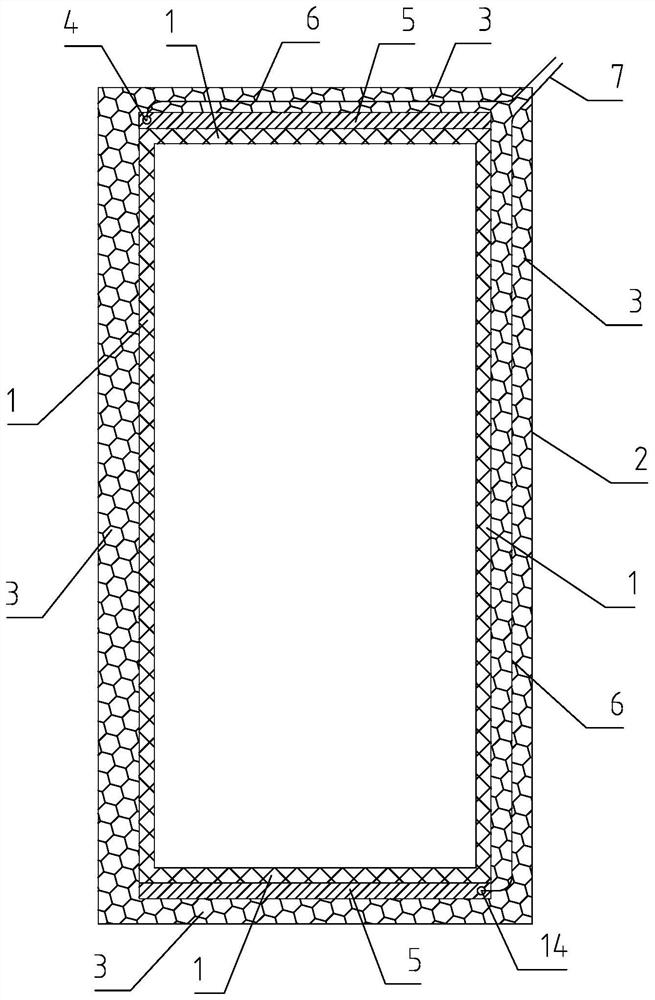

[0061] Figure 1-Figure 28 It is an embodiment of a hollow glass manufacturing method of the present invention. It can be seen in the figure that it includes a glass door main assembly 12 and a conductive heating assembly 13. The glass door main assembly 12 includes a coated glass 8, and one side of the coated glass 8 is provided with There is a white glass 9, and an inner heat-insulating soft glue 1 is provided between the coated glass 8 and the white glass 9, and a hollow glass cavity 11 is arranged on the inner side of the inner heat-insulating soft glue 1 between the coated glass 8 and the white glass 9, and the hollow The inside of the glass chamber 11 is filled with an inert gas; the coated glass 8 includes a conductive coating layer 10 on its inner surface, and the inner heat-insulating soft glue 1 is located around the inner surface of the conductive coating layer 10 and ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com