Ni3Al-based single-crystal high-temperature alloy and preparation method thereof

A high-temperature alloy based single crystal technology, applied in the field of alloys, can solve problems such as difficult to meet the temperature bearing capacity, aggravate the precipitation of TCP or MC phase, high alloy density and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

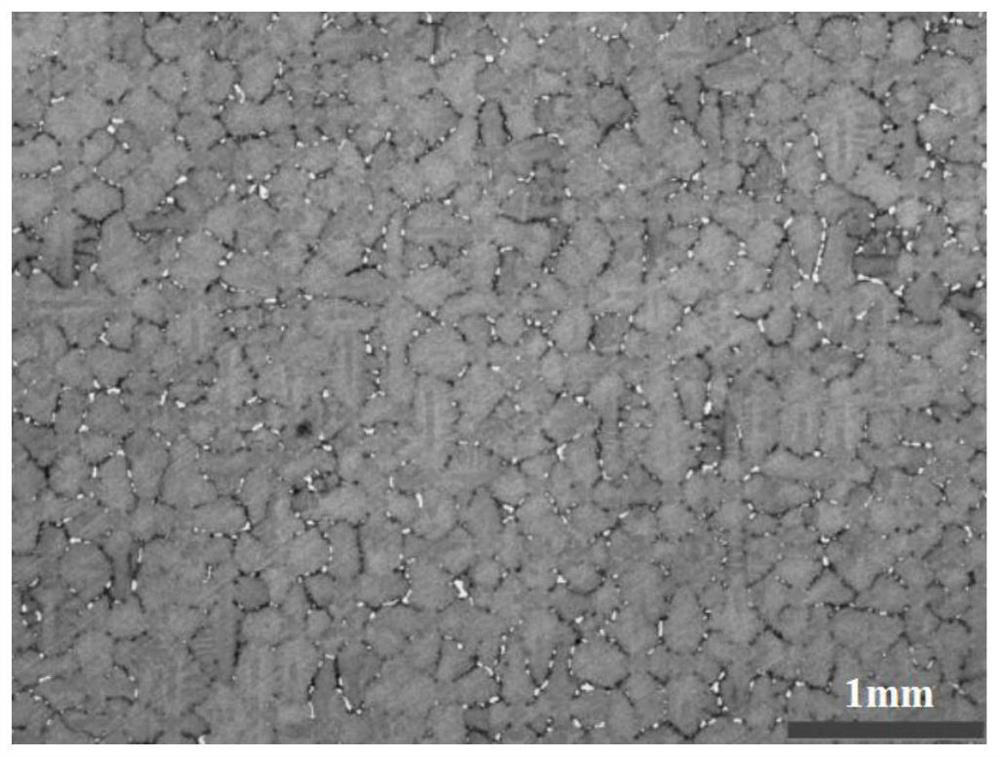

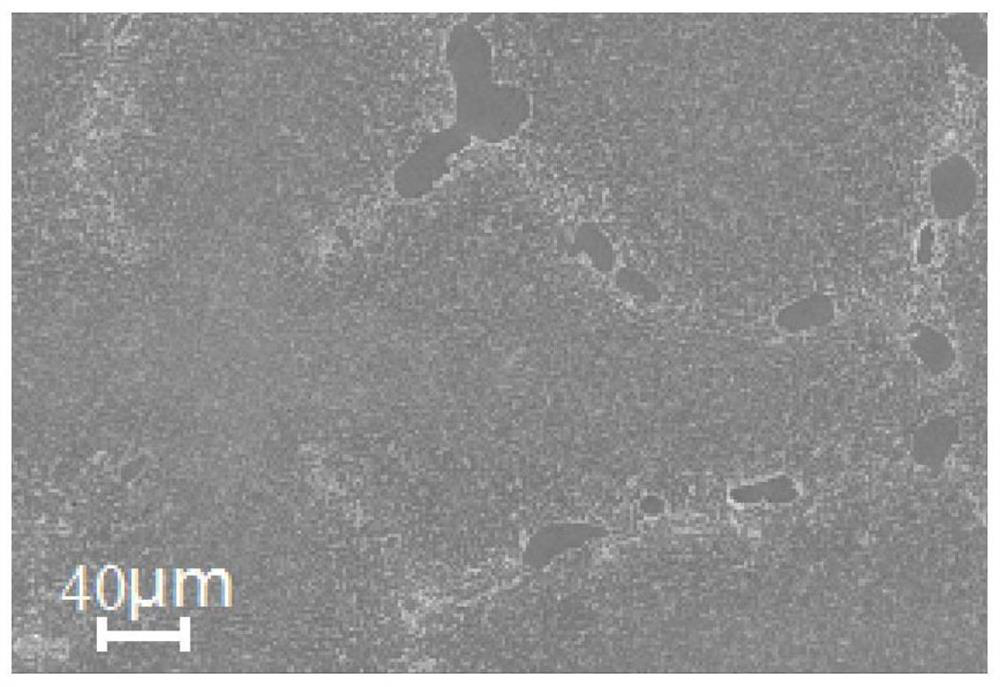

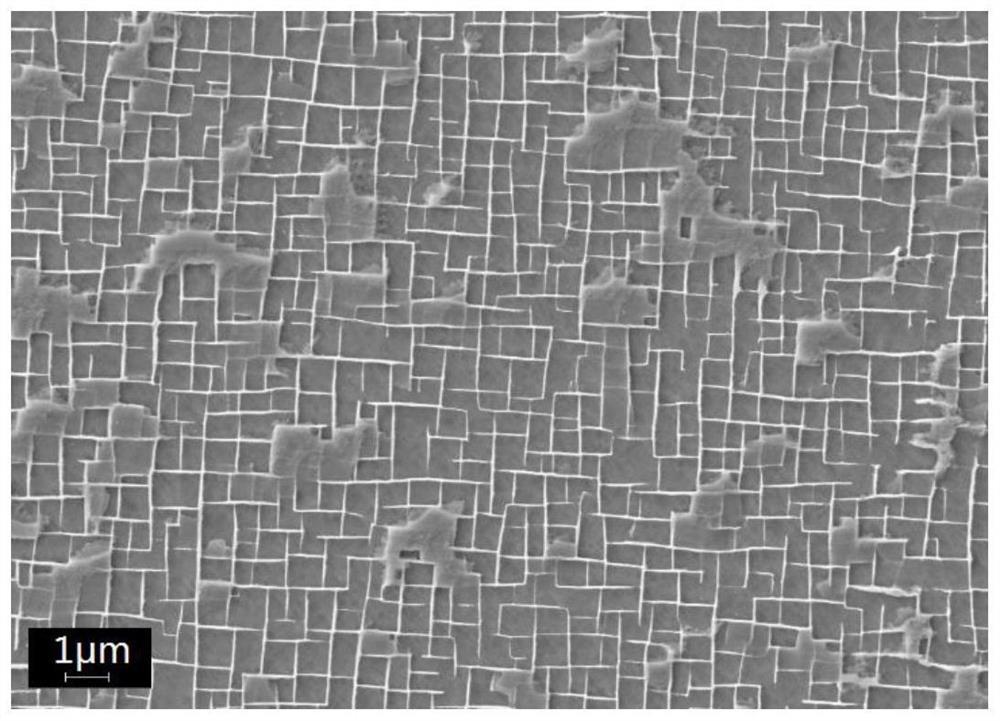

Examples

preparation example Construction

[0058] The present invention also provides the Ni described in the above-mentioned technical scheme 3 A method for preparing an Al-based single crystal superalloy, comprising the following steps:

[0059] Smelting and casting the alloy raw materials in sequence to obtain the alloy billet;

[0060] performing spiral crystal selection and heat treatment on the alloy cast slab in turn to obtain the Ni 3 Al-based single crystal superalloy.

[0061] In the invention, alloy raw materials are smelted and cast in sequence to obtain an alloy billet.

[0062] In the present invention, the alloy raw materials preferably include pure Ni, pure Al, pure Mo, pure Re, pure Ta, pure Hf, pure C, pure Y and Ni-Ce alloys. In the present invention, the mass percentage of Ce in the Ni—Ce alloy is preferably 65%. The present invention does not have special limitation to the specific source and addition amount of described alloy raw material, in order to obtain the Ni that satisfies the chemical ...

Embodiment 1

[0081] The alloy raw materials are: pure Ni, pure Al, pure Mo, pure Re, pure Ta, pure Hf, pure C, pure Y and Ni-Ce alloy, wherein the mass percentage of Ce in the Ni-Ce alloy is 65%;

[0082] Design Ni 3 The chemical composition of Al-based single crystal superalloy is Al 7.6wt.%, Mo 8.0wt.%, Ta3.0wt.%, Re 3.0wt.%, Hf 0.1wt.%, Y 0.01wt.%, Ce 0.005wt.%. %, C0.005wt.%, the remainder of Ni and unavoidable impurities;

[0083] By design Ni 3 The chemical composition of the Al-based single crystal superalloy, the pure Ni which accounts for 50wt.% of the total pure Ni content is placed in the bottom of the crucible of the ZGJL-0.025 vacuum induction furnace, and then pure Mo, pure Re, pure Ta, Pure Hf, pure C and Ni-Ce alloy, cover the remaining pure Ni on the alloy raw material, evacuate the cavity of the vacuum induction furnace to below 1Pa, turn on the heating, increase the heating power step by step until the metal raw material block melts, at 1520 ℃ for 20 minutes for the f...

Embodiment 2

[0100] The raw material alloys are: pure Ni, pure Al, pure Mo, pure Re, pure Ta, pure Hf, pure C, pure Y and Ni-Ce alloy, wherein the mass percentage of Ce in the Ni-Ce alloy is 65%;

[0101] Design Ni 3 The chemical composition of Al-based single crystal superalloy is Al 7.6wt.%, Mo 9.5wt.%, Ta3.0wt.%, Re 3.0wt.%, Hf 0.1wt.%, Y 0.01wt.%, Ce 0.005wt.%. %, C0.005wt.%, the remainder of Ni and unavoidable impurities;

[0102] By design Ni 3 The chemical composition of the Al-based single crystal superalloy, the pure Ni which accounts for 50wt.% of the total pure Ni content is placed in the bottom of the crucible of the ZGJL-0.025 vacuum induction furnace, and then pure Mo, pure Re, pure Ta, Pure Hf, pure C and Ni-Ce alloys, cover the remaining pure Ni on the alloy raw materials, evacuate the cavity of the vacuum induction furnace to below 1Pa, turn on the heating, and increase the heating power step by step until the metal raw materials are melted, at 1540 ℃ for 20 minutes for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com