Three-stage solution heat treatment method for Al-Zn-Mg-Cu system aluminum alloy

A heat treatment method and three-stage solid solution technology, which is applied in the field of heat treatment to improve the corrosion resistance of Al-Zn-Mg-Cu aluminum alloys, can solve the problems of affecting the aging strengthening effect and reducing the supersaturation of solid solution on the surface of alloy materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

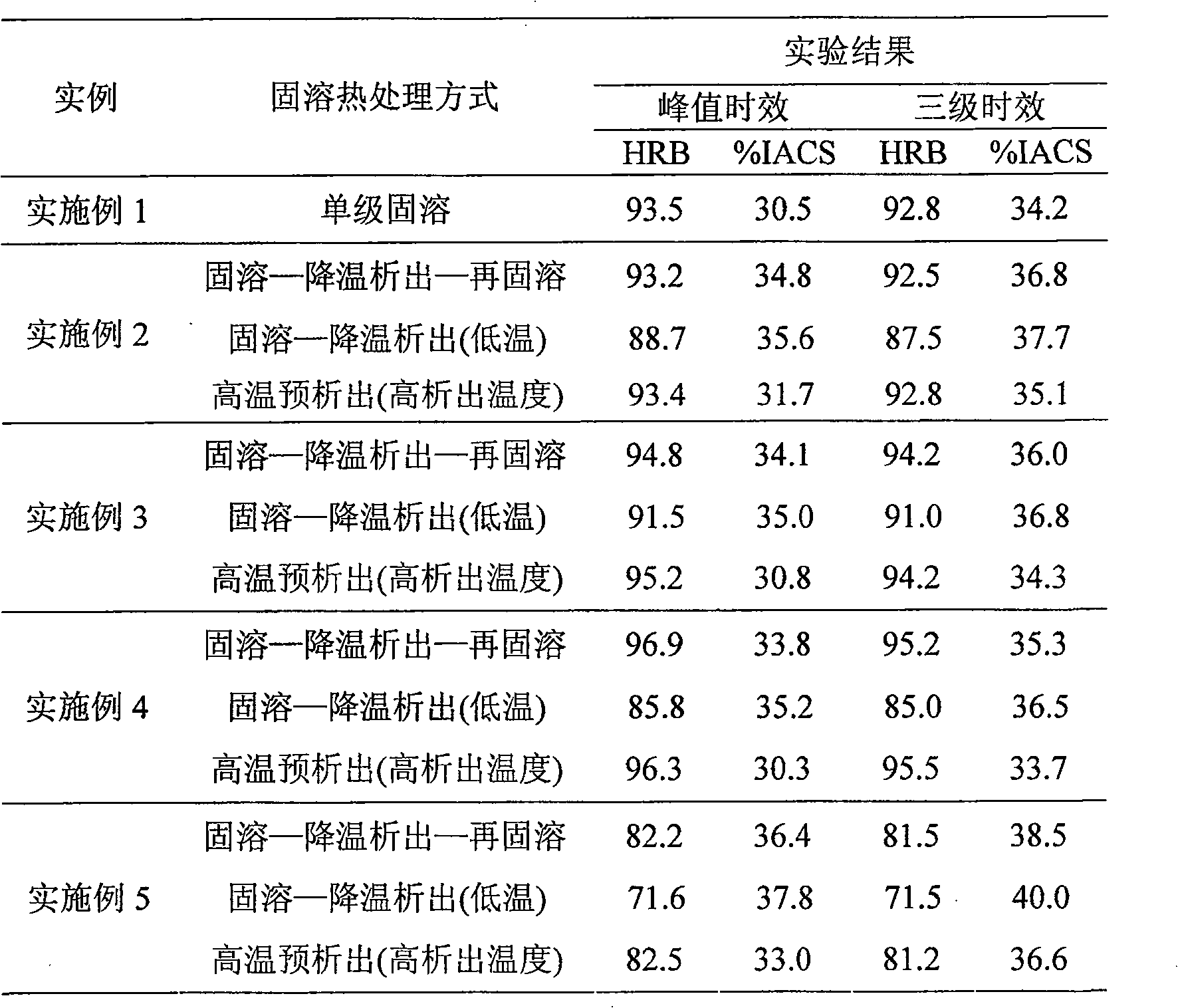

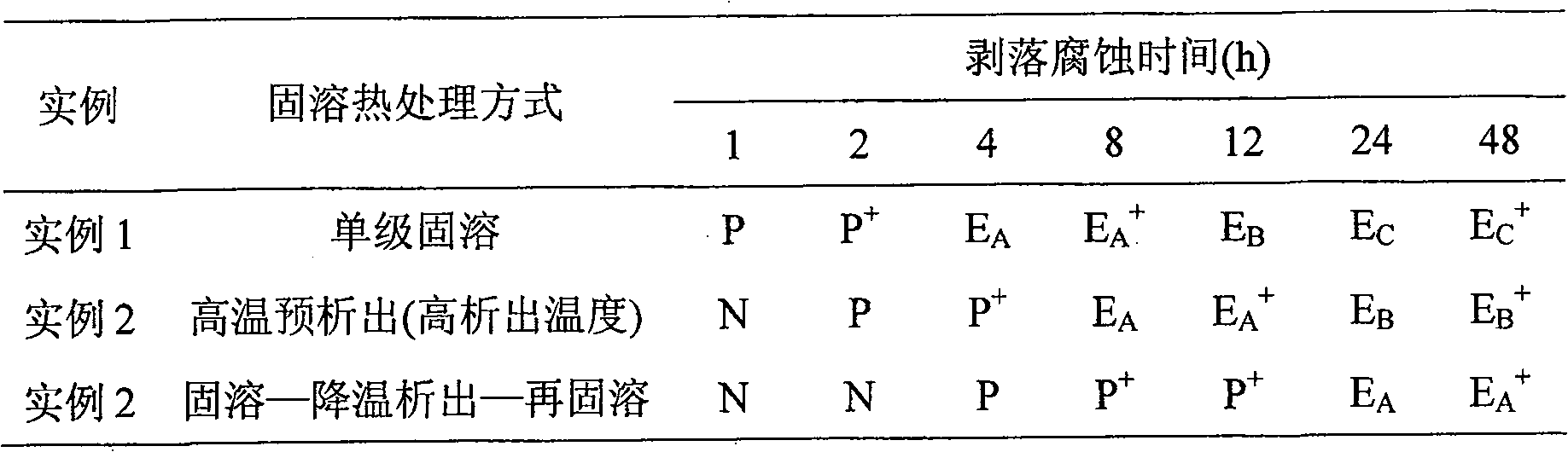

Embodiment 1

[0020] The chemical composition of the experimental alloy is: Al-6.5Zn-2.4Mg-2.2Cu-0.13Zr (mass fraction). The solid solution adopts conventional solution treatment, that is, it is directly kept at 480°C for 3 hours and then quenched in water. The quenching transfer time is less than 5s, and the aging is carried out in two ways: peak aging (130°C / 24h) and tertiary aging (130°C / 24h→180°C / 1h→130°C / 24h). After the aging, the hardness and electrical conductivity tests were carried out, and the experimental results are shown in Table 1. The peak aged samples were then subjected to exfoliation corrosion ratings. The evaluation results are shown in Table 3.

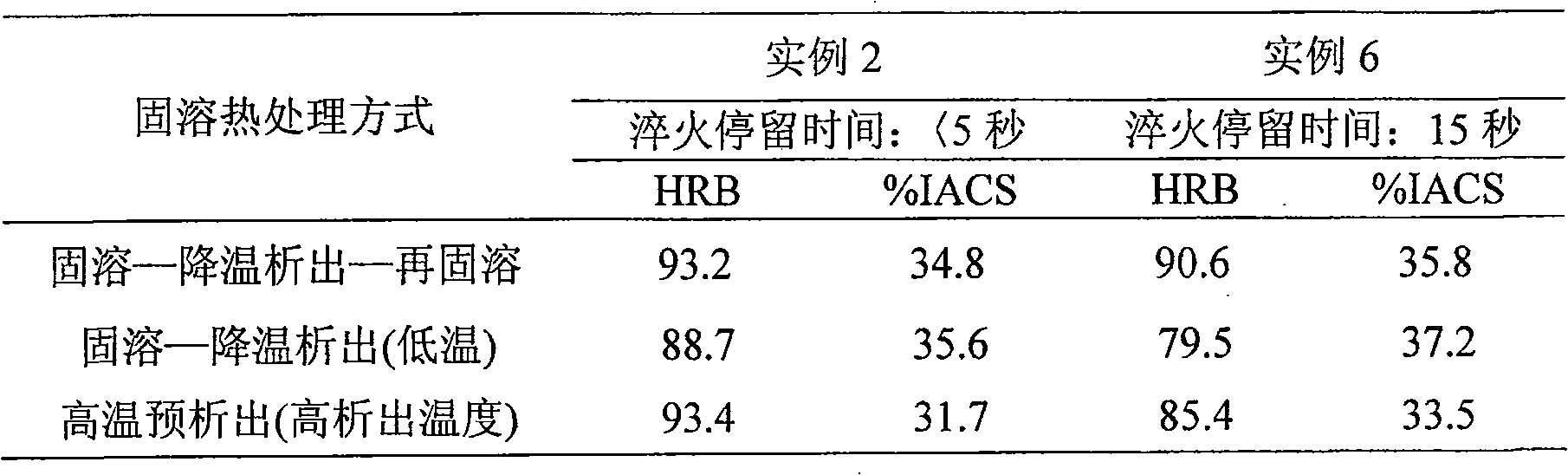

Embodiment 2

[0022] The chemical composition of the experimental alloy is: Al-6.5Zn-2.4Mg-2.2Cu-0.13Zr (mass fraction). Solution treatment using three-stage solution heat treatment and high temperature pre-precipitation process comparison:

[0023] (1) Three-stage solution heat treatment: the sample is directly heated to 470 ° C for 1 h, then cooled to 380 ° C at a rate of 0.5 ° C / min and maintained for 0.5 h, then heated to 450 ° C at a rate of 5 ° C / min, and kept 2min.

[0024] (2) Solid solution-cooling precipitation (low temperature precipitation) treatment: the first stage adopts the same treatment method as the first stage of the three-stage solution heat treatment, and then cools down to 420°C at a rate of 0.5°C / min and holds for 30 minutes.

[0025] (3) High-temperature pre-precipitation (high-temperature precipitation) treatment: the first stage adopts the same treatment method as the first stage of the three-stage solution heat treatment, and then the temperature is lowered ...

Embodiment 3

[0028] The chemical composition of the experimental alloy is: Al-8.6Zn-2.5Mg-2.2Cu-0.16Zr (mass fraction). Solution treatment adopts three-stage solution heat treatment and high-temperature pre-precipitation process, and the specific implementation process is as follows:

[0029] (1) Three-stage solution heat treatment: heat up to 480°C with the furnace and hold for 2 hours, then cool down to 400°C at a rate of 1°C / min and hold for 5 hours, then raise the temperature to 470°C at a rate of 5°C / min, hold time for 5min.

[0030] (2) Solid solution-cooling precipitation (low temperature precipitation) treatment: the first stage adopts the same treatment method as the first stage of the three-stage solution heat treatment, and then cools down to 430°C at a rate of 0.5°C / min and holds for 30min.

[0031] (3) High-temperature pre-precipitation (high-temperature precipitation) treatment: the first stage adopts the same treatment method as the first stage of the three-stage solution h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com