Reverse spraying standing wave dedusting and cooling tower

A technology of cooling tower and standing wave, which is applied in the direction of the sedimentation tank, the feeding/discharging device of the sedimentation tank, and the use of liquid separating agent, etc., which can solve the problems of high exhaust gas temperature, high failure rate, and poor dust removal effect. Achieve low temperature, increase contact area, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

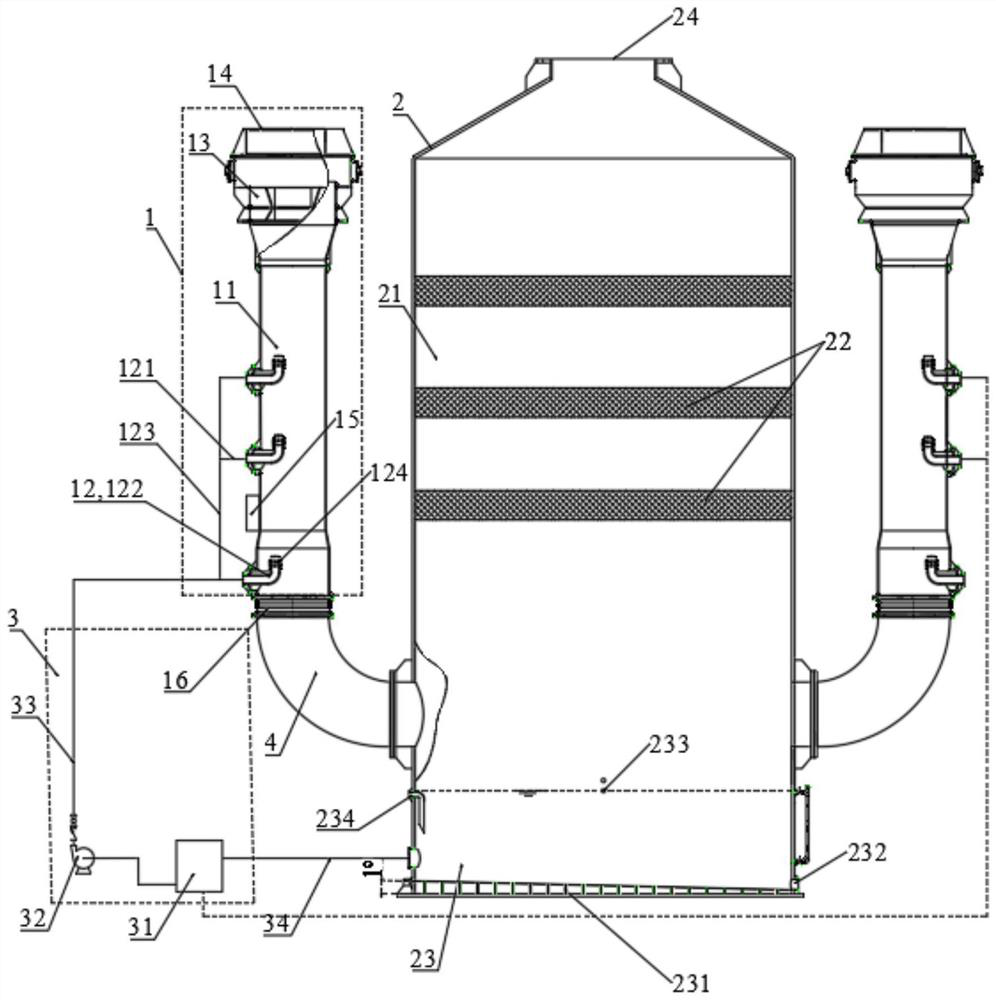

[0031] refer to figure 1 , figure 2 , a reverse spray standing wave dedusting and cooling tower, including a spray body 1 and a gas-liquid separation tower 2, and the spray body 1 communicates with the middle and lower ends of the gas-liquid separation tower 2 through an arc bend 4;

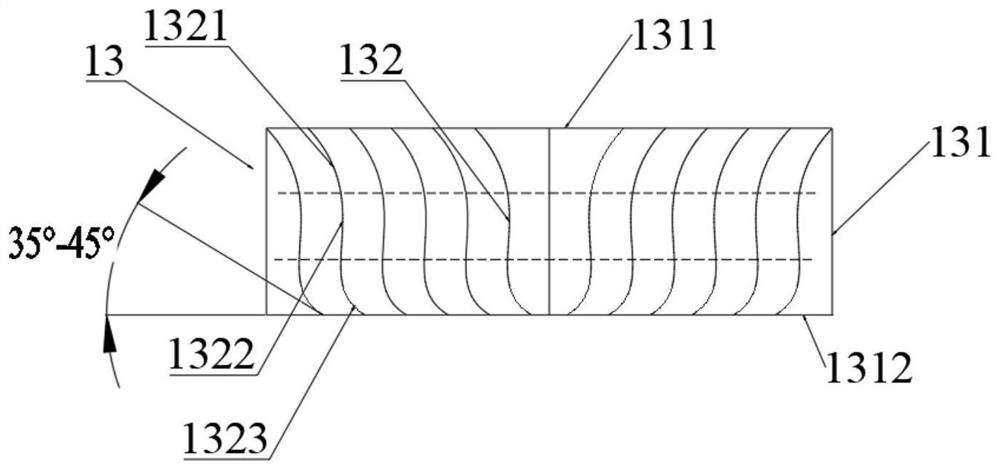

[0032] The spray body 1 includes a pipe body 11, an injection assembly 12 arranged inside the pipe body 11, and a flow guide assembly 13; one end of the pipe body 11 is a gas inlet 14, and the gas inlet 14 is connected to the gas-liquid separation tower 2 The connection part is provided with a guide assembly 13 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com