Cyclone mechanical cooling equipment

A technology of cooling equipment and cyclone, applied in lighting and heating equipment, mobile duct type heat exchanger, indirect heat exchanger, etc., can solve the problem of poor dust cooling effect, save power, better cooling effect, dust removal better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

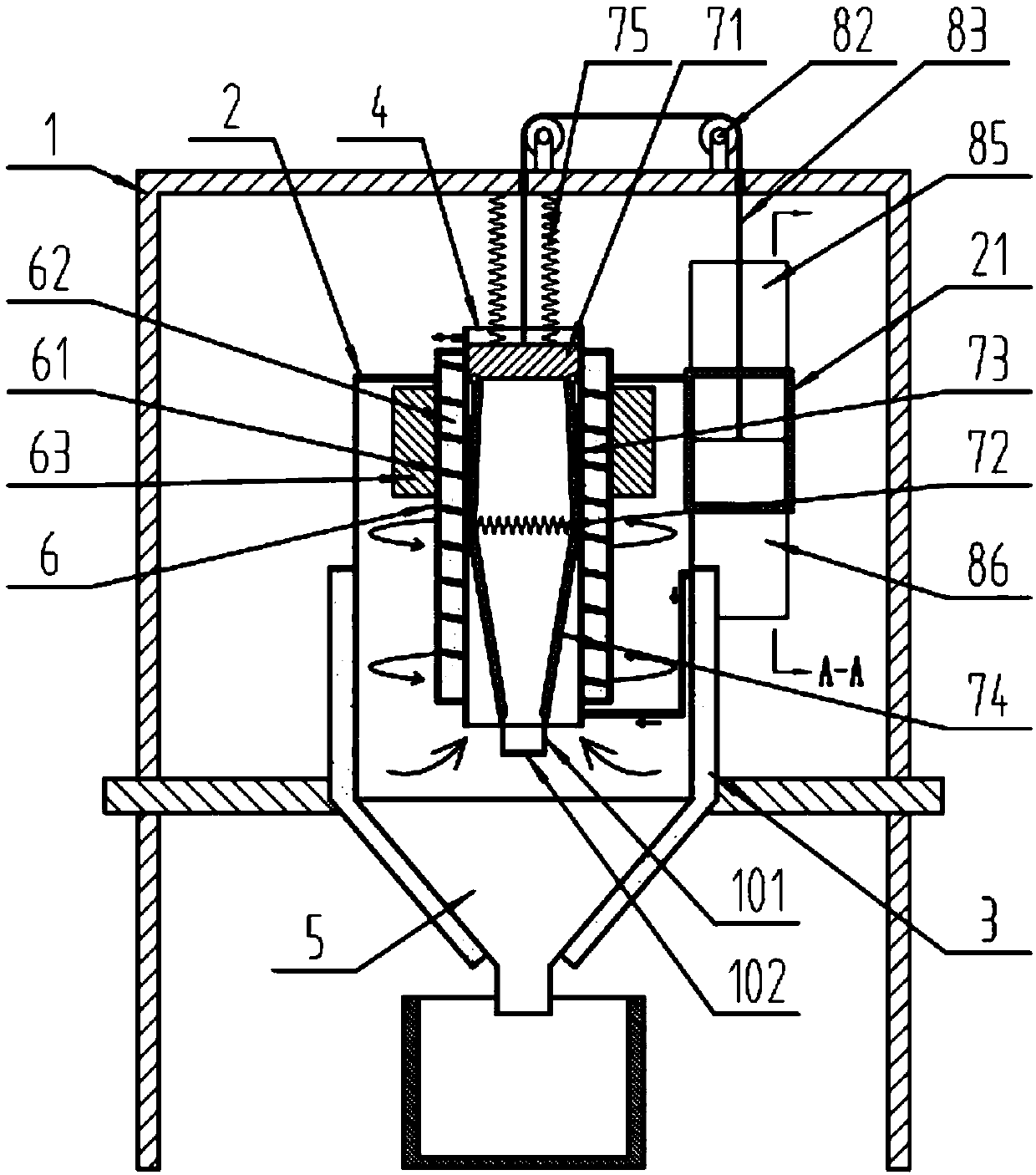

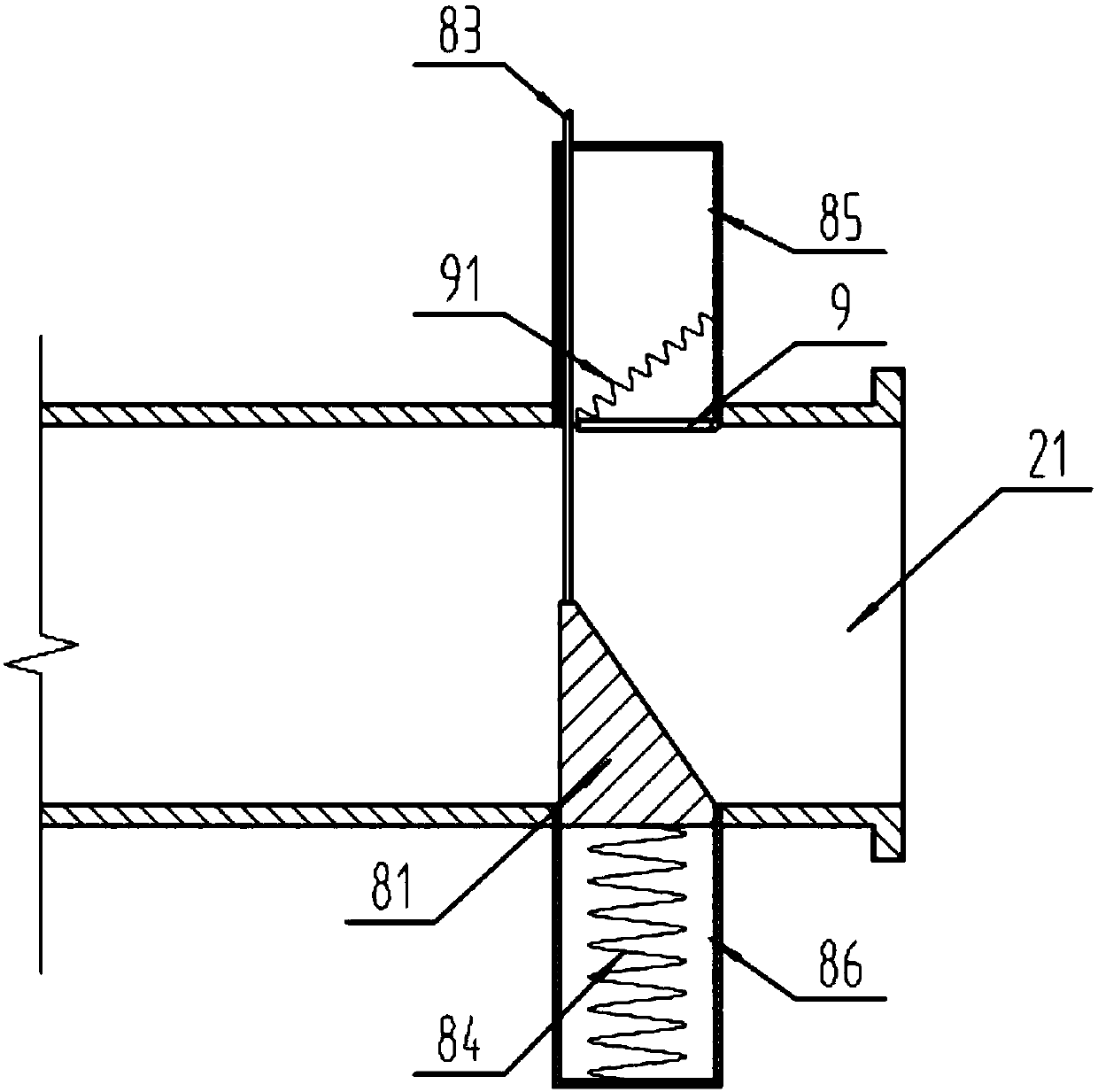

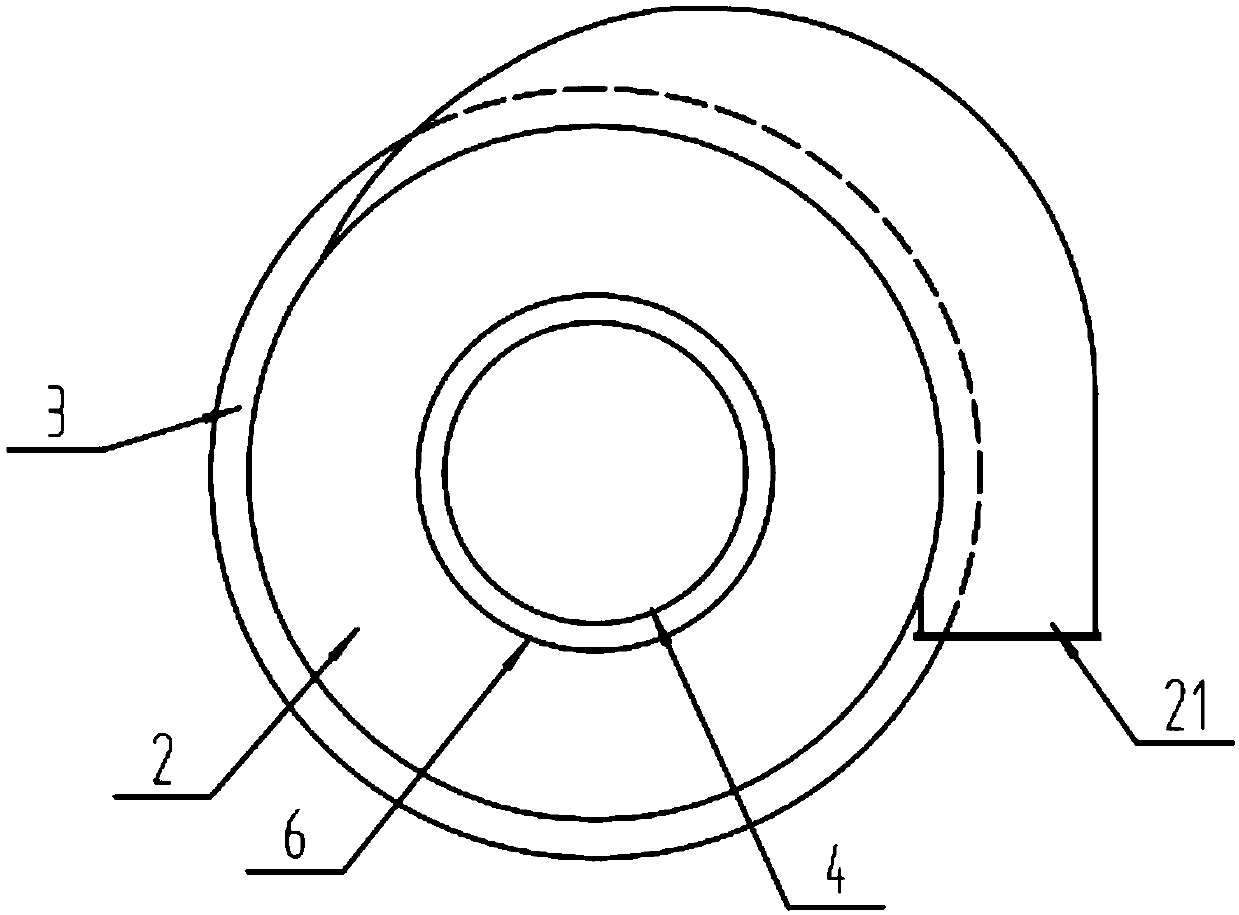

[0027] The reference signs in the drawings of the description include: support frame 1, outer cylinder 2, air inlet pipe 21, cooling cylinder 3, air outlet pipe 4, dust removal ash hopper 5, rotating drum 6, liquid delivery screw 61, cooling chamber 62, Rotating blade 63, connecting block 71, the first compression spring 72, the first articulation lever 73, the second articulation lever 74, the third compression spring 75, wedge block 81, steering wheel 82, connecting rope 83, the second compression spring 84, Buffer groove 85 , sliding groove 86 , windshield 9 , extension spring 91 , third hinged rod 101 , and horizontal pushing block 102 .

[0028] Such as Figure 1-3 As shown, the cyclone mechanical cooling equipment includes a support frame 1, an outer cylinder 2 is arranged on the support frame 1, an air inlet pipe 21 is provided on the upper part of the outer cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com