Preparation method of negative electrode material, negative electrode material and application of negative electrode material

A technology of negative electrode material and silicon negative electrode, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of volume expansion hindering the application and promotion of silicon negative electrode materials, reducing cycle life, volume expansion, etc., achieving good uniformity and improving Electrical conductivity, the effect of suppressing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

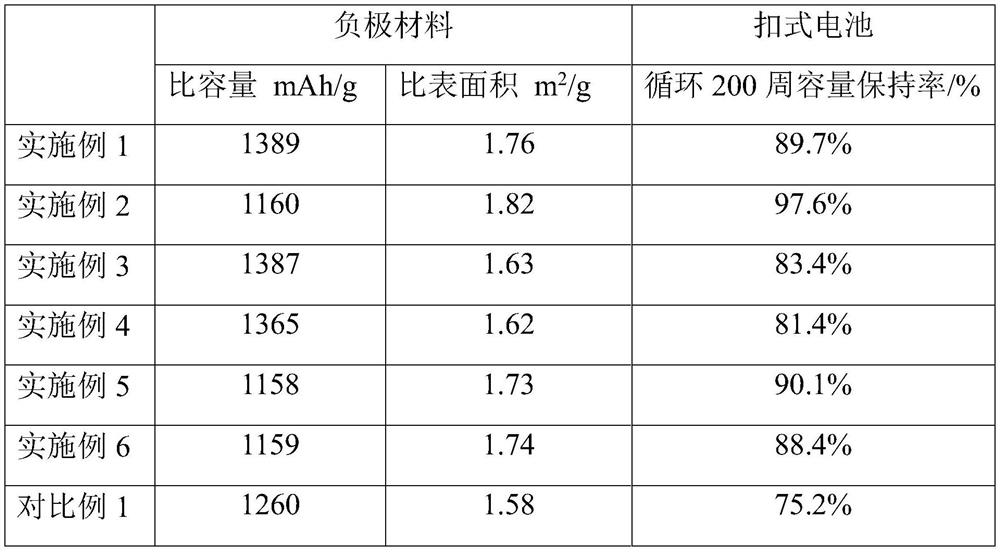

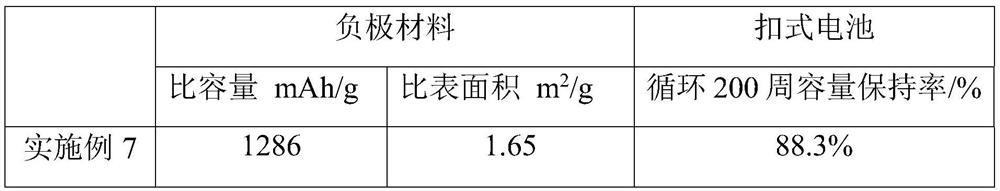

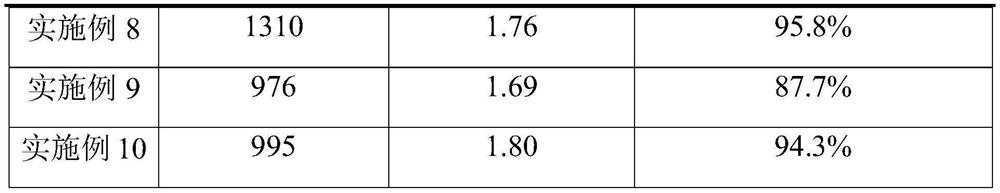

Examples

Embodiment 1

[0035] A preparation method of negative electrode material, comprising the following steps:

[0036] S1. Preparation of silicon negative electrode precursor material: Take 11mL tetraethyl orthosilicate and add dropwise to 10mL 0.02mol / L sodium hydroxide alkaline solution, stir at room temperature for 30min, and then transfer to the liner lined with polytetrafluoroethylene At the same time, the reactor was placed in a blast drying oven, kept at 70°C for 5h, cooled to room temperature naturally, and the obtained white precipitate was washed with ethanol and deionized water until the pH of the supernatant was neutral. properties, and then centrifuged at 1500r / min, the obtained white precipitate was vacuum-baked in an oven at 80°C for 12h to obtain a silicon negative electrode precursor material.

[0037] S2. Preparation of silicon negative electrode material: disperse the silicon negative electrode precursor material obtained in step S1 in 5 mL of 10 mM FeCl 3 ·6H 2 Add 5mL of ...

Embodiment 2

[0041] A preparation method of negative electrode material, comprising the following steps:

[0042] S1. Preparation of silicon negative electrode precursor material: Take 11mL tetraethyl orthosilicate and add dropwise to 10mL 0.02mol / L sodium hydroxide alkaline solution, stir at room temperature for 30min, and then transfer to the liner lined with polytetrafluoroethylene At the same time, the reactor was placed in a blast drying oven, kept at 70°C for 5h, cooled to room temperature naturally, and the obtained white precipitate was washed with ethanol and deionized water until the pH of the supernatant was neutral. properties, and then centrifuged at 1500r / min, the obtained white precipitate was vacuum-baked in an oven at 80°C for 12h to obtain a silicon negative electrode precursor material.

[0043] S2. Preparation of silicon negative electrode material: disperse the silicon negative electrode precursor material obtained in step S1 in 5 mL of 10 mM FeCl 3 ·6H 2 Add 5mL of ...

Embodiment 3

[0048] The difference from Example 1 is the preparation of the silicon negative electrode material in step S2.

[0049] Preparation of silicon negative electrode material: disperse the silicon negative electrode precursor material obtained in step S1 in 5mL of 10mM FeCl 3 ·6H 2 Add 5mL of 10mM ethanol solution of isophthalic acid dropwise to the ethanol solution of O, and stir the mixed solution at 50°C for 5h; Roasting in a nitrogen tube furnace, the calcination temperature is 500° C., and the constant temperature time is 1 h, to obtain a porous carbon-coated silicon negative electrode material.

[0050] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com