A pulsed negative pressure drilling shale shaker

A vibrating screen and negative pressure technology, which is used in wellbore flushing, earthmoving, wellbore/well components, etc., can solve the problems of limited negative pressure peak value and low adsorption efficiency of drilling fluid negative pressure, and avoid pressure holding. , The effect of improving the screening capacity and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

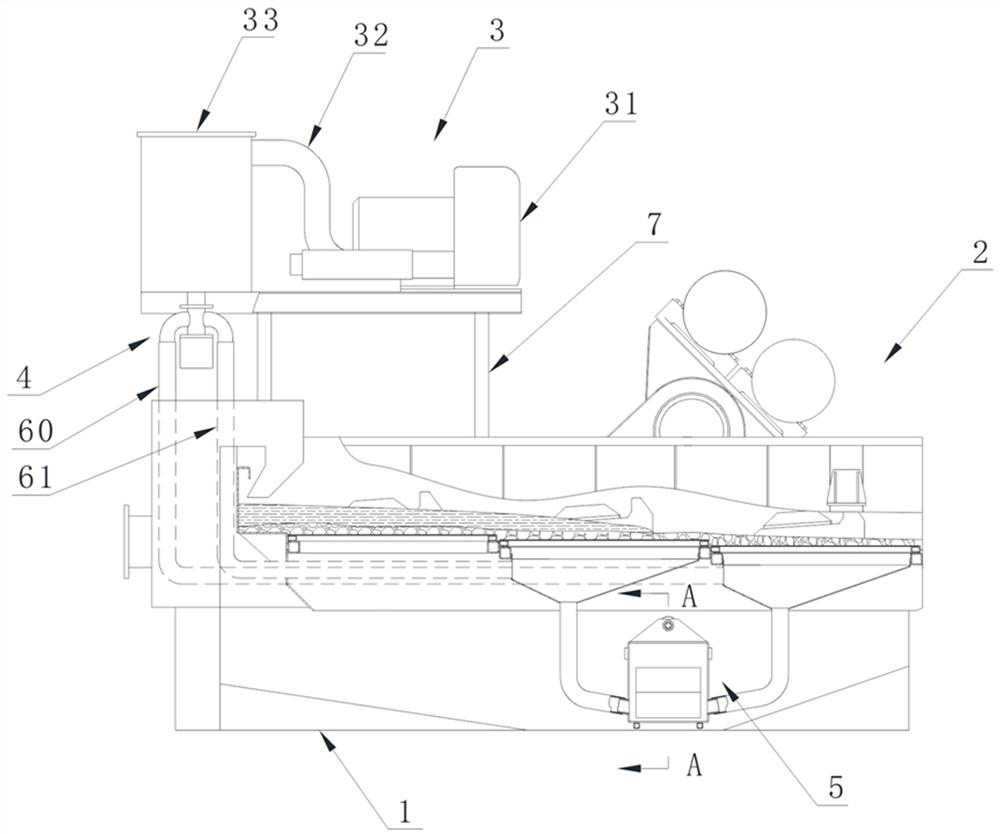

[0048] Please refer to figure 1 , a pulse negative pressure drilling shale shaker, comprising: a base 1, and a screening device 2, a negative pressure device 3, a pulse distributor 4 and a liquid discharge device 5 all installed on the base 1. The negative pressure device 3 sends pulsed negative pressure to the negative pressure device 3 through the pulse distributor 4 to improve the recovery efficiency of the drilling fluid. The negative pressure adsorption efficiency of the liquid is improved, and the working capacity of the negative pressure device can be fully utilized, which greatly improves the efficiency of the negative pressure device.

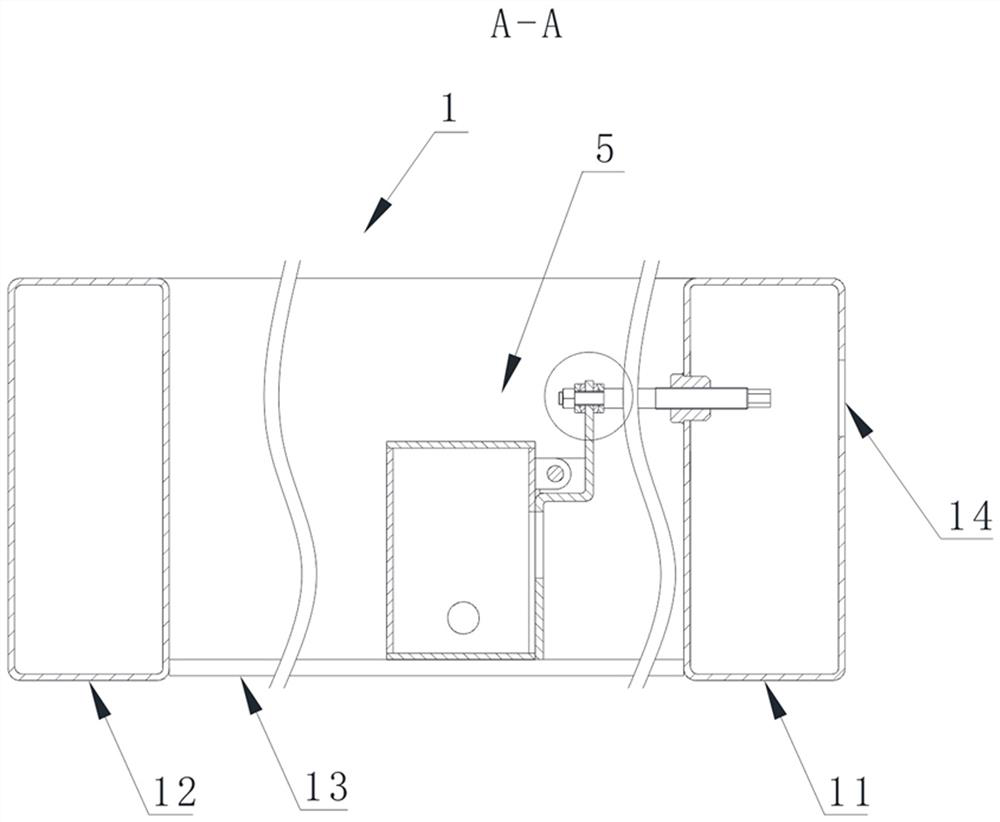

[0049] Please refer to figure 2 , the base 1 includes a first rectangular steel 11 and a second rectangular steel 12 that are evenly spaced and arranged transversely, the first rectangular steel 11 and the second rectangular steel 12 are located on both sides of the vibrating screen, the first rectangular steel 11 and the second rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com