Anti-seismic steel mesh thermal insulation wall convenient to decorate and reform

A technology of thermal insulation wall and anti-seismic steel, which is applied in the direction of thermal insulation, walls, and anti-seismic, etc., which can solve the problems affecting the anti-seismic performance and crack resistance of the wall, reducing the safety and reliability of the wall, and reducing the overall structural strength of the wall, etc. , to achieve the effect of convenient pre-embedded layout of line pipes, improved safety and reliability, improved seismic performance and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

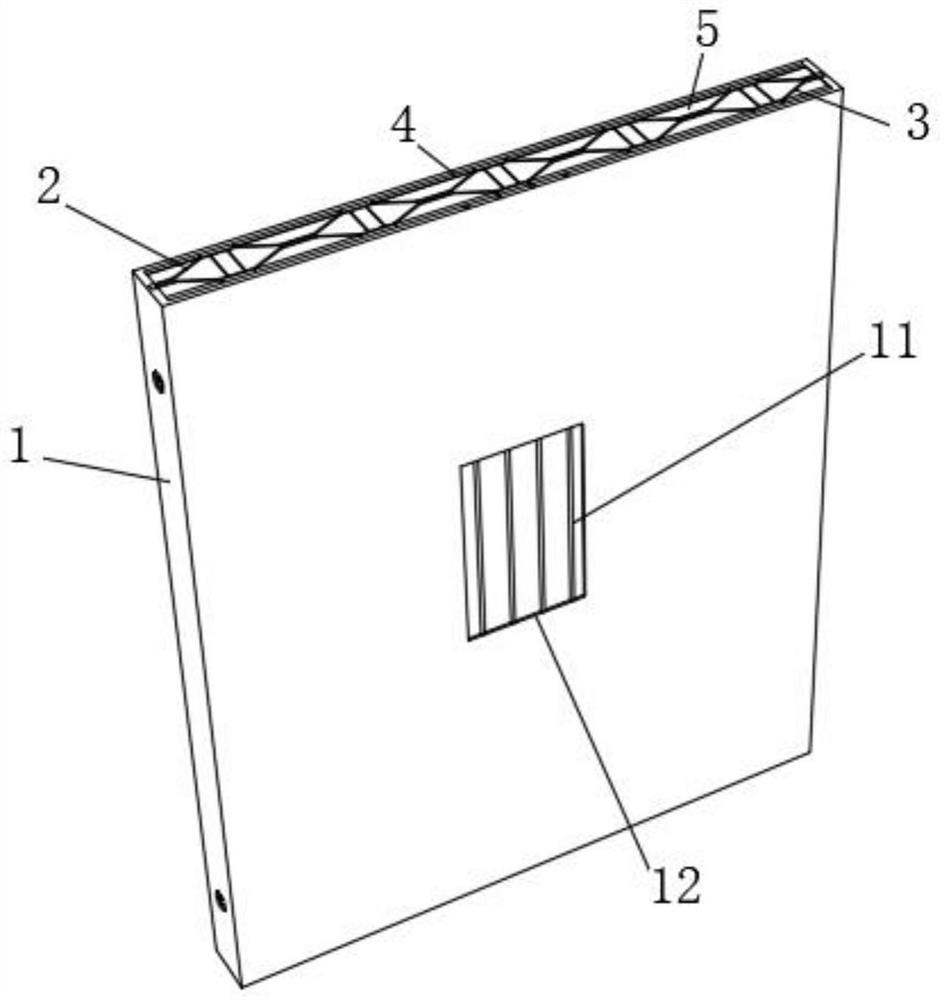

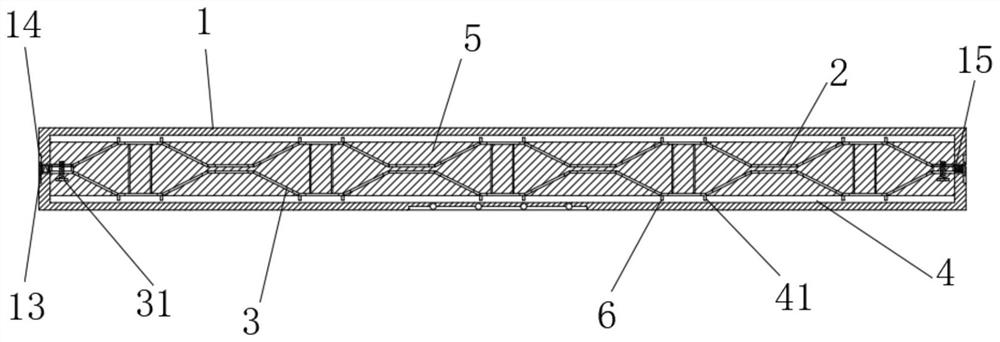

[0030] Example: Reference Figure 1-5 Shown is an anti-seismic steel mesh insulation wall that is convenient for decoration and transformation, including a wall panel frame 1 .

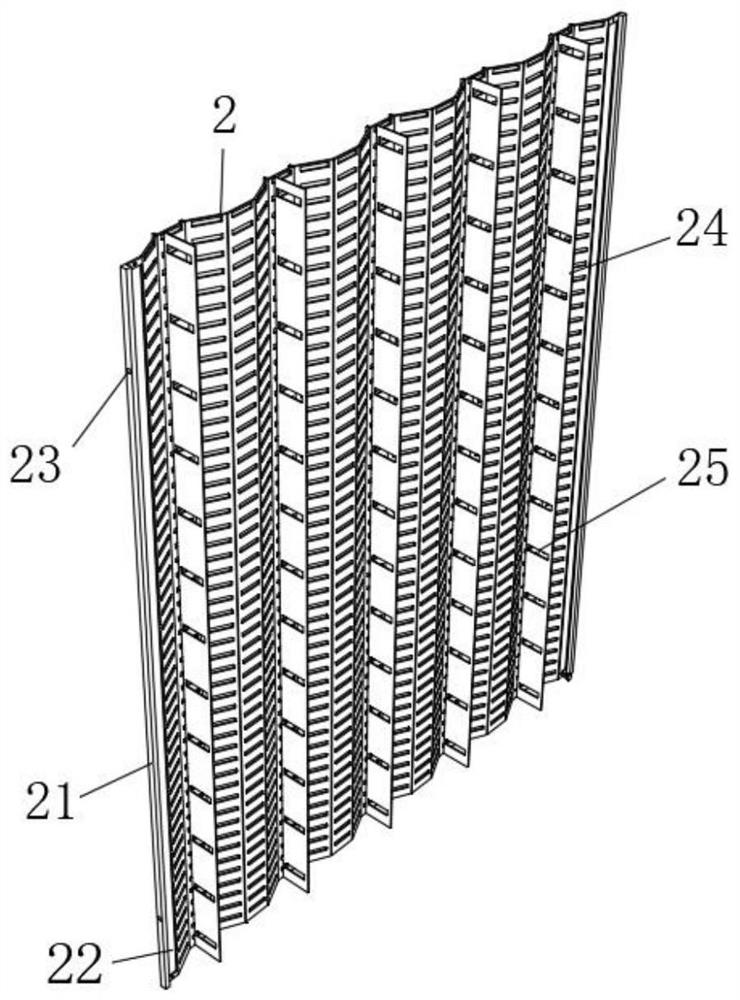

[0031] The interior of the wall panel frame 1 is provided with a steel grid frame b3, and the steel grid frame b3 is fixedly connected with the steel grid frame a2 through the assembly bolt 31, and the inner side walls of the wall panel frame body 1 are fixedly installed with an insulation layer 4, and the steel grid A concrete layer 5 is poured between the frame a2 and the steel grid frame b3, the surface of the insulation layer 4 is provided with tightening grooves 41 at intervals, and the outer surfaces of the steel grid frame a2 and the steel grid frame b3 are fixedly connected with tightening bars 6 at intervals, The tightening strips 6 are correspondingly embedded inside the tightening groove 41 to improve the structural stability of the steel grid a2 and the steel grid b3 and prevent the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com