Thermocuring printing method and printing device thereof

A thermal curing, print head technology, applied in the field of 3D printing, can solve problems such as difficulty in printing models, and achieve the effect of improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

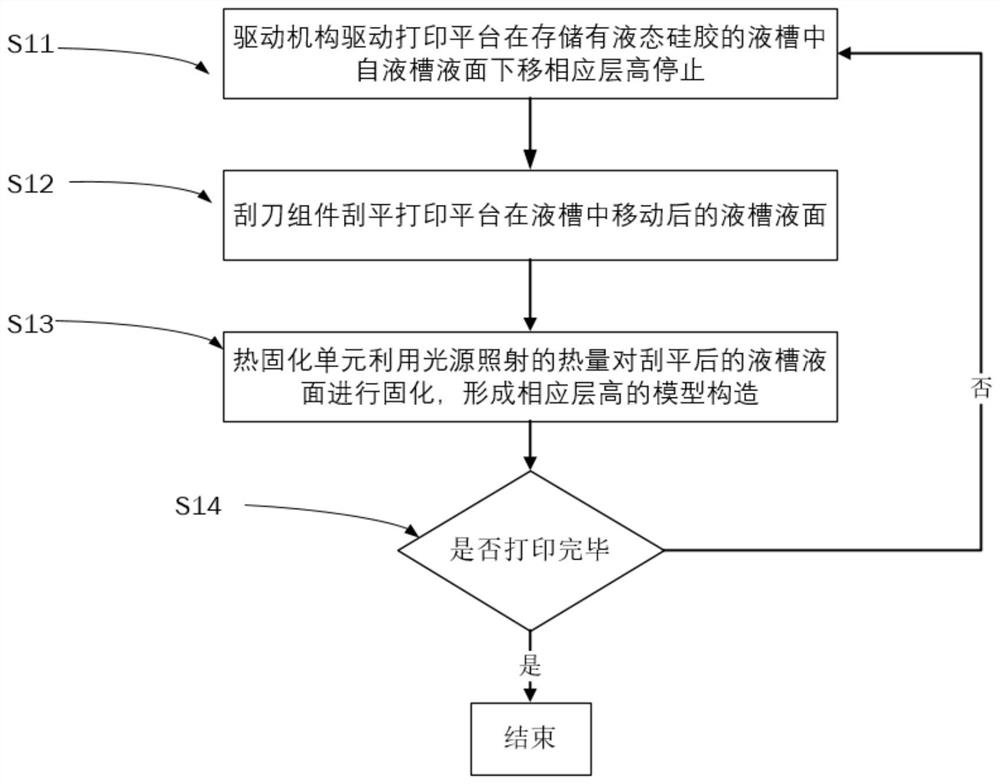

[0027] A thermal curing printing method in this embodiment includes:

[0028] S11. The driving mechanism drives the printing platform to move down from the liquid level of the liquid tank to stop at the corresponding layer height in the liquid tank storing the heat-curing fluid material;

[0029] S12. The scraper assembly scrapes the liquid level of the liquid tank after the printing platform moves in the liquid tank;

[0030] S13. The thermal curing unit solidifies the leveled liquid surface of the liquid tank to form a model structure with a corresponding layer height;

[0031] S14. Determine whether the printing is complete, if yes, end; if not, repeat S11-S14.

[0032] The heat-curing fluid material can be heat-curing silicone rubber, heat-curing resin, heat-curing glue, heat-curing liquid silicone, etc. In other words, the corresponding type of heat-curing fluid material can be selected as the printing material according to the performance requirements of the printed mod...

Embodiment 2

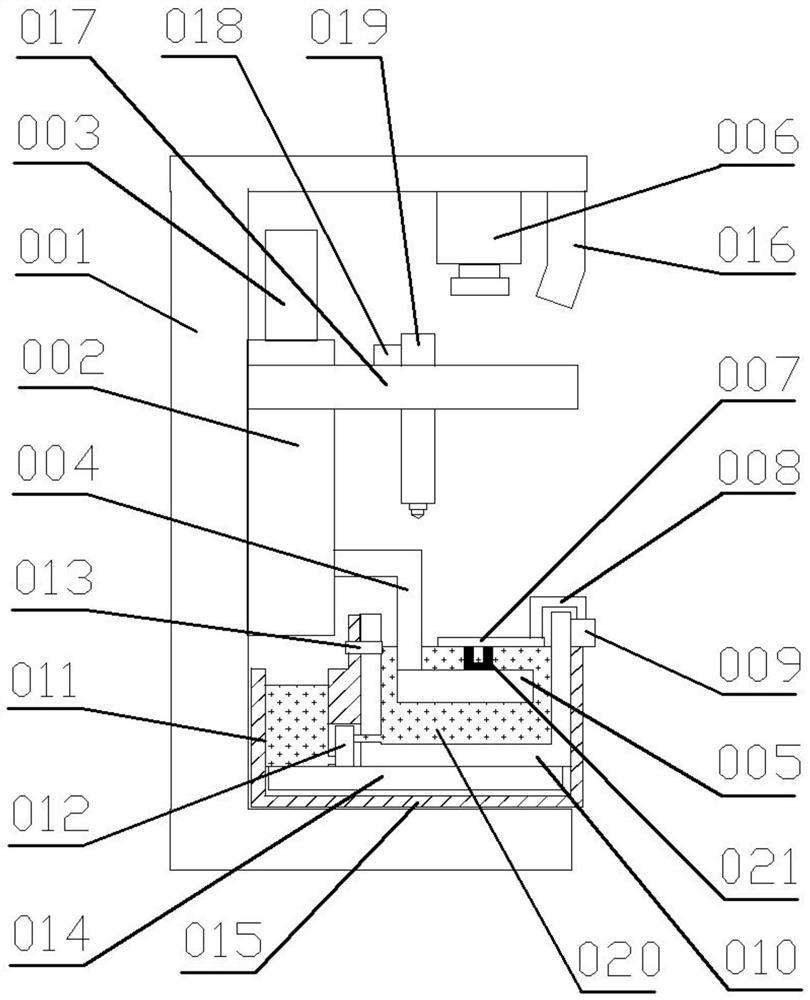

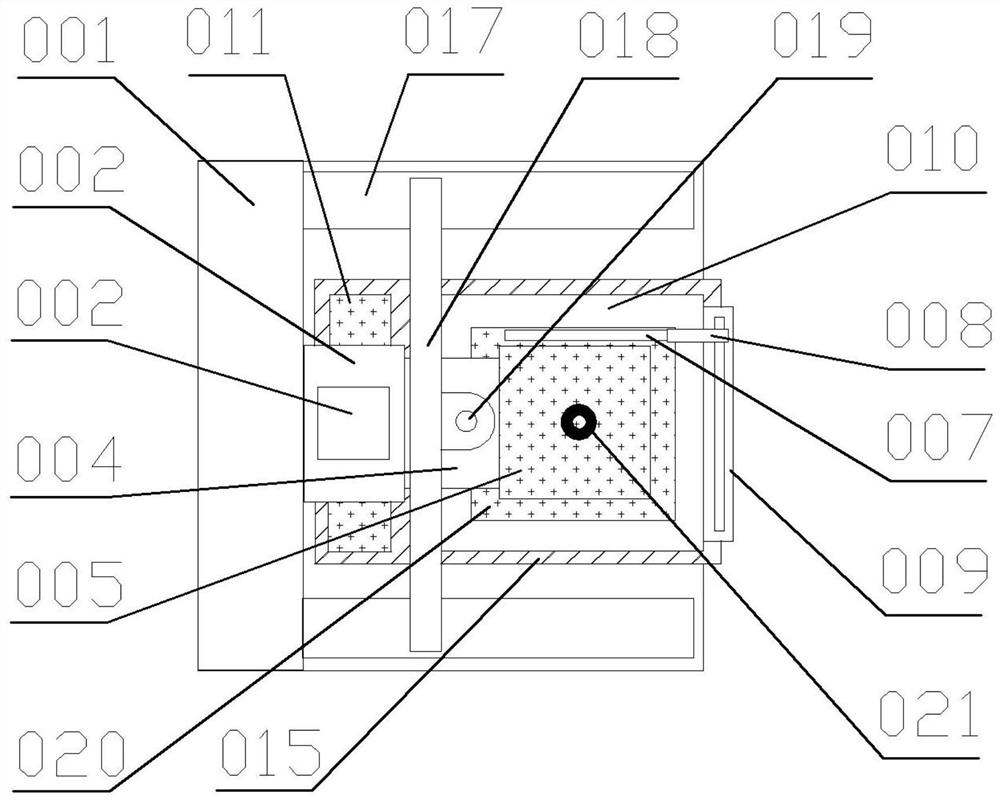

[0046] combine figure 2 with 3 , this embodiment proposes a thermosetting printing device, which is used to implement a thermosetting printing method described in any one of the technical solutions in Embodiment 1, including: a printing platform 005, a liquid tank 010, a refrigerator 014, and a scraper assembly , the thermal curing unit 006 and the driving mechanism, wherein the driving mechanism is used to drive the printing platform 005 to move; the refrigerator 014 is located outside the liquid tank 010, and the liquid tank 010 is used to hold liquid silicone; the scraper assembly is used to scrape the printing platform 005 the liquid surface after moving in the liquid tank; the thermal curing unit 006 is used to solidify the liquid surface of the liquid tank after scraping to form a model 021 structure with a corresponding layer height.

[0047] If it is printing with support, it also includes an extruding print head 019 located above the liquid tank 010, and the extrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com