Manufacturing method of multi-structure 3D printing orthopedic insole

A technology of 3D printing and manufacturing method, which is applied in the direction of 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problem of not being able to adjust individually, and achieve the effect of facilitating material switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The manufacturing method of a kind of multi-structure 3D printing orthopedic insole shown in this embodiment comprises the following steps:

[0038]a. Obtain the three-dimensional data of the individual foot through a three-dimensional scanner, including the length and width of the sole, establish a three-dimensional model of the foot and determine the three-dimensional curved surface of the sole;

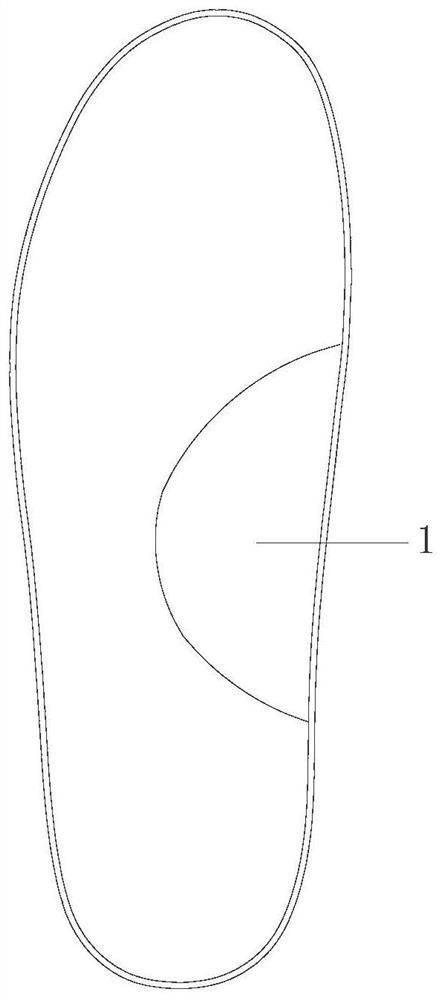

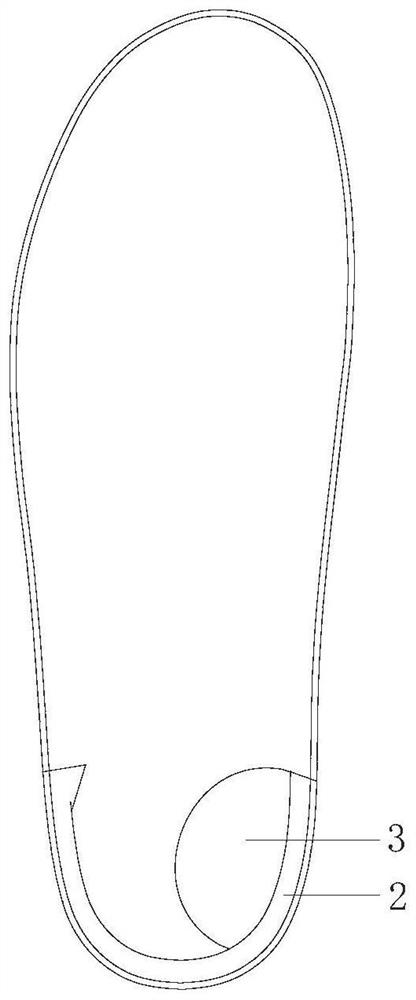

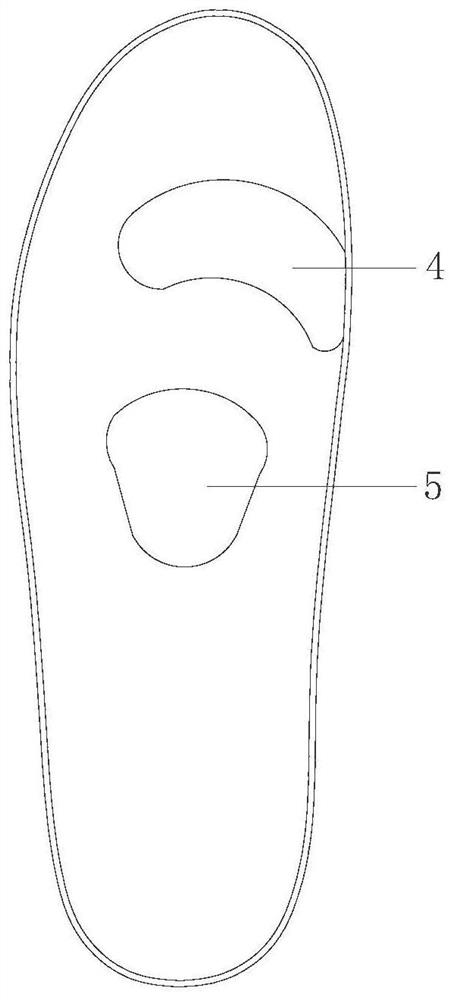

[0039] b. Obtain the pressure data of the individual foot through the pressure tester, determine the foot shape and divide the sole of the foot according to the pressure data combined with the three-dimensional data of the foot obtained in step a, and divide the insoles to be made into corresponding divisions like the sole divisions The same number of production areas; specifically, the health status of the foot can be analyzed according to the pressure data, so as to determine which foot disease it has, and divide the sole of the foot into at least two areas according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com