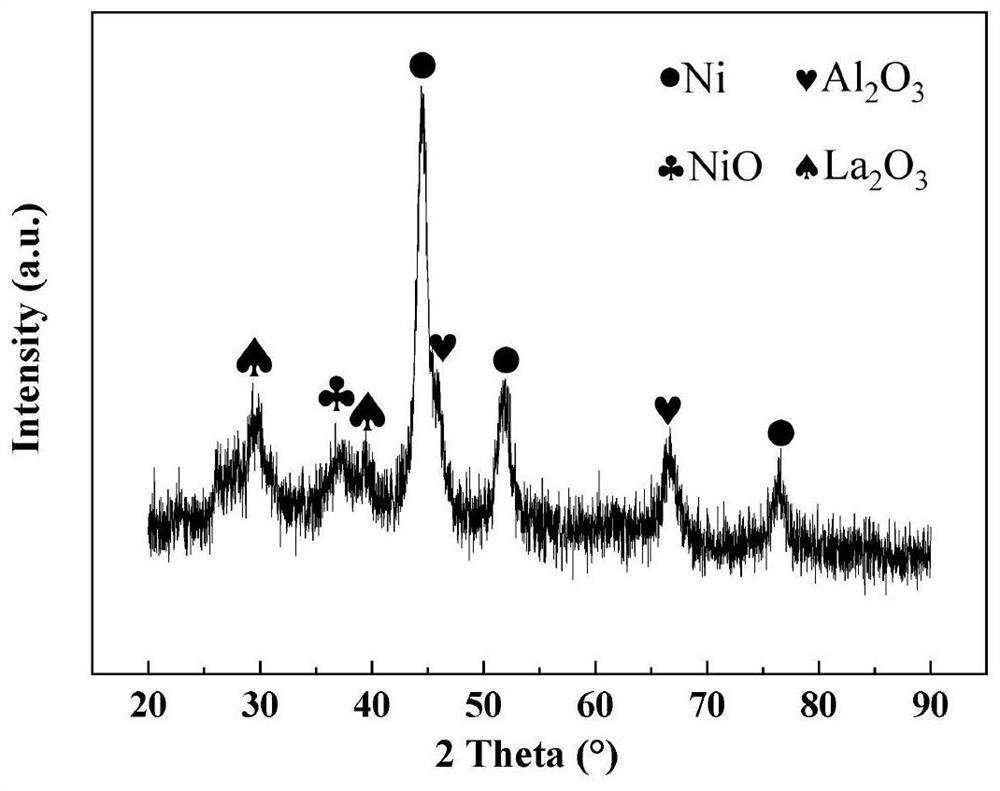

La modified Ni/Al2O3 catalyst, preparation method and application

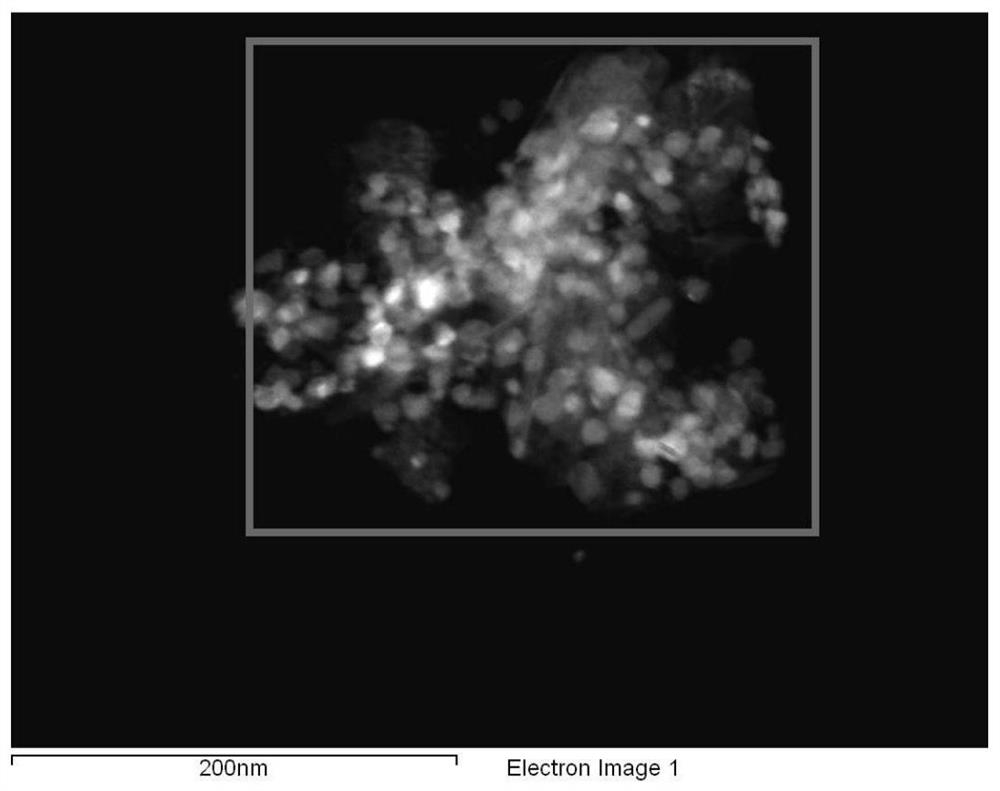

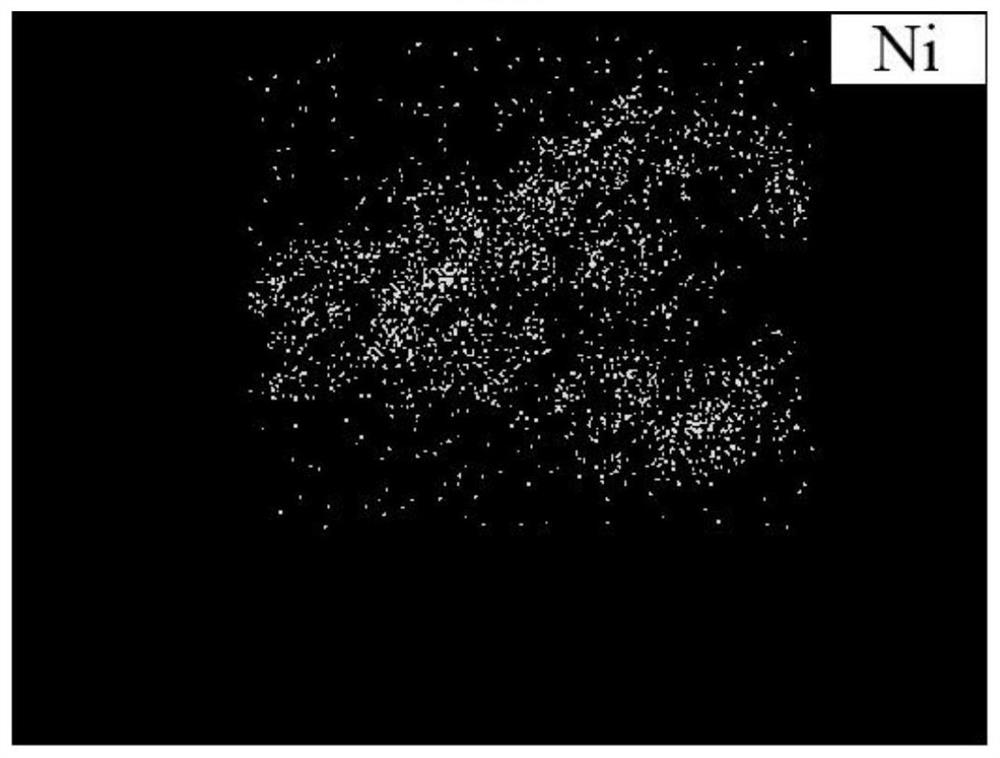

A catalyst and modification technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of reducing agglomeration, simple equipment and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A kind of La modified Ni / Al 2 o 3 The preparation method of catalyst, step is as follows:

[0060] (1) Weigh 7.433g Ni(NO 3 ) 2 ·6H 2 O, 1.329g La(NO 3 ) 3 ·6H 2 O, 22.075gAl(NO 3 ) 3 9H 2 O, dissolved in 100ml deionized water in a 250ml beaker to prepare solution I; weigh 18.834g Na 2 CO 3 Dissolve 100ml of deionized water in a 250ml beaker to prepare solution II; weigh 0.5g of polyethylene glycol 2000 and dissolve it in a 500ml beaker with 200ml of deionized water to prepare solution III.

[0061] (2) Under the condition of an oil bath at 90°C, solution I and solution II were added dropwise to solution III at a rate of 2-3 drops / second at the same time using a constant pressure dropping funnel, and stirred for 1 hour to form a light green precipitate. After natural cooling, filter, wash with deionized water until neutral, and then wash twice with absolute ethanol.

[0062] (3) Disperse the precipitate obtained in step (2) in 150 ml of absolute ethanol, an...

Embodiment 2

[0067] A kind of La modified Ni / Al 2 o 3 Application of catalyst in hydrogenation reaction of organic liquid hydrogen storage materials:

[0068] La-modified Ni / Al prepared with hydrogen storage material aziridine carbazole and Example 1 2 o 3 Catalyst mass ratio 10:1 ratio carries out hydrogenation reaction, and the steps are as follows:

[0069] Add 2 g of aziridine carbazole and 0.2 g of catalyst into 40 ml of n-hexane solvent to carry out the hydrogenation experiment of organic liquid hydrogen storage materials. The reaction pressure is 7 MPa, the reaction temperature is 150 ° C, and the rotation speed is 600 r / min. The hydrogenation reaction rate of carbazole is as follows Figure 10 shown.

Embodiment 3

[0071] A kind of La modified Ni / Al 2 o 3 Application of catalyst in hydrogenation reaction of organic liquid hydrogen storage materials:

[0072] La-modified Ni / Al prepared with hydrogen storage material aziridine carbazole and Example 1 2 o 3 Catalyst mass ratio 10:1 ratio carries out hydrogenation reaction, and the steps are as follows:

[0073] Add 2 g of aziridine carbazole and 0.2 g of catalyst into 40 ml of n-hexane solvent to carry out the hydrogenation experiment of organic liquid hydrogen storage materials. The reaction pressure is 5 MPa, the reaction temperature is 140 ° C, and the rotation speed is 600 r / min. The hydrogenation reaction rate of carbazole is as follows Figure 11 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com