Self-supporting high-molecular polymer membrane as well as preparation method and application thereof

A high molecular polymer and polymer membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve difficult large-scale preparation, output power density needs to be further improved, porous material preparation method and process complex problems, to achieve the effect of simple and easy method and process, high energy conversion efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also includes the preparation method of any one of the above-mentioned high-efficiency salinity difference power generation polymer membranes, comprising the following steps:

[0027] 1) Add Kevlar fibrils and potassium hydroxide into a container containing dimethyl sulfoxide in parts by weight, and stir for 7 days at a rotating speed of 200-500r / min;

[0028] 2) placing the aramid nanofiber dispersion formed by stirring, and the high molecular polymer in a container filled with dimethyl sulfoxide solvent, and stirring at a speed of 200-500r / min for 3-5h;

[0029] 3) The dispersion liquid stirred in 2) is vacuum-filtered for 2-72 hours, and finally dried at 40-80° C. for 2-5 hours and peeled off to obtain a high-molecular polymer membrane for salt difference power generation.

[0030] The present invention also provides the application of any one of the above polymer membranes in salinity difference power generation.

Embodiment 1

[0033] The preparation method of ANFs-SL and the application of salinity difference power generation comprise the following steps:

[0034] 1) Put 11 mg of Kevlar 29 fibrils and 9 mg of potassium hydroxide into a beaker filled with 20 mL of dimethyl sulfoxide solvent, and stir at a speed of 250 r / min for 7 days to form an aramid nanofiber dispersion.

[0035]2) Put the aramid nanofiber dispersion prepared in 1) and 80 mg SL in a beaker, stir at a stirring speed of 350 r / min for 4 hours to obtain a uniform mixed liquid.

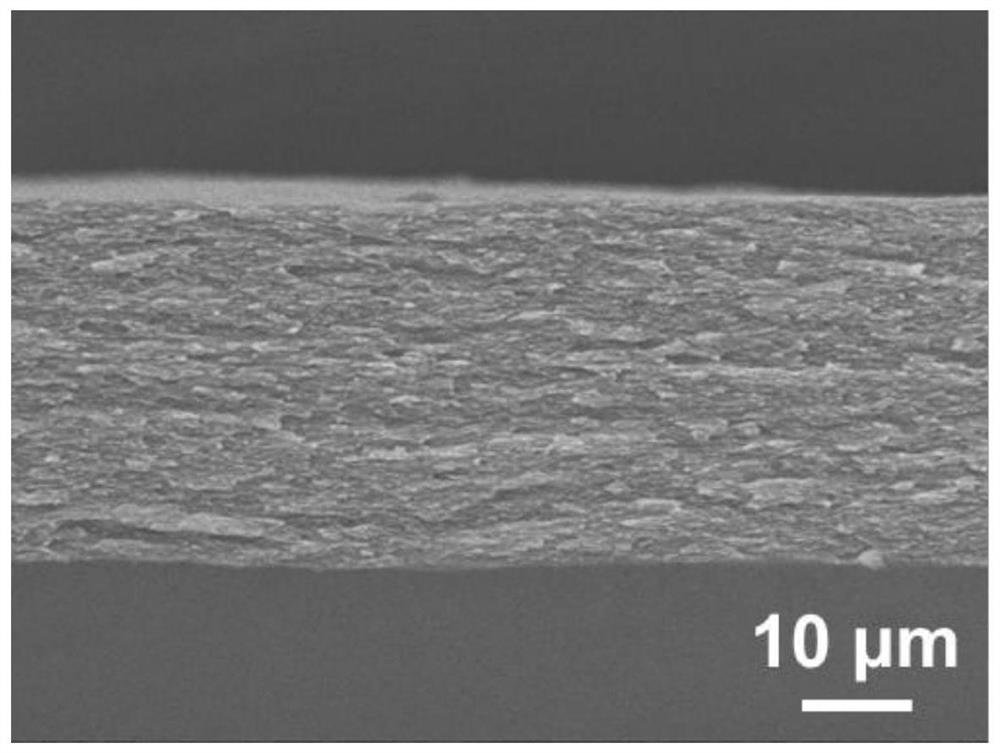

[0036] 3) The mixed solution obtained in step 2) is subjected to vacuum suction filtration, at room temperature, suction filtration for 6 hours, and dried at 40° C. for 2 hours to peel off to obtain an ANFs-SL film with a film thickness of about 32 μm; the ANFs- The SL film material is a two-dimensional layered structure, and the percentage content of SL is 79.6wt%.

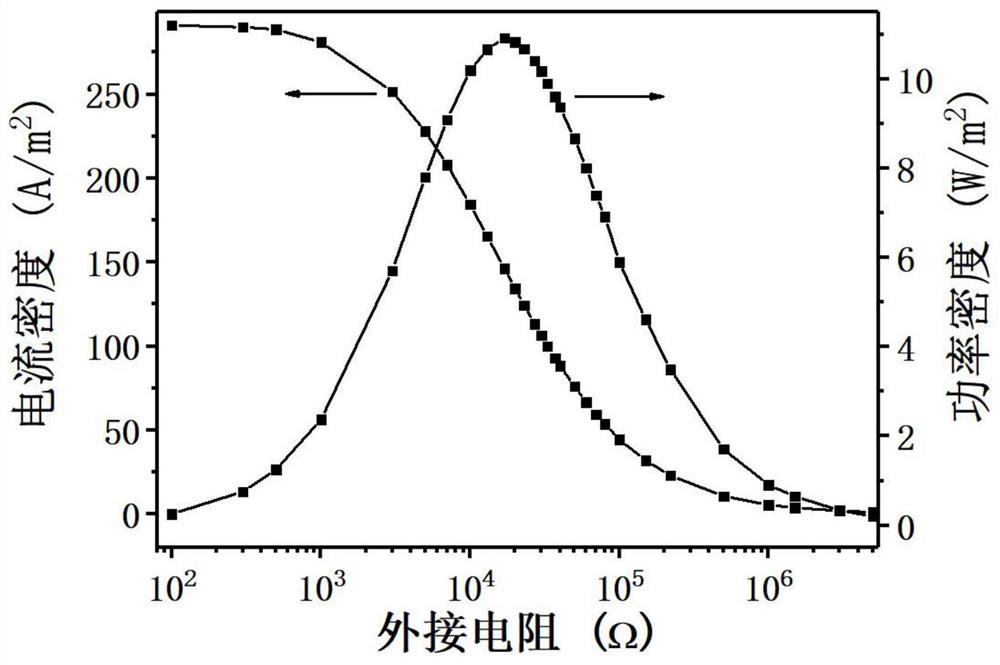

[0037] 4) Salt difference power generation performance test: ANFs-SL membrane is used to sep...

Embodiment 2

[0039] The preparation method of ANFs-PSS and the application of salinity difference power generation comprise the following steps:

[0040] 1) Put 45 mg of Kevlar 49 fibrils and 9 mg of potassium hydroxide into a beaker filled with 100 mL of dimethyl sulfoxide solvent, and stir at a speed of 300 r / min for 7 days to form an aramid nanofiber dispersion.

[0041] 2) Put the aramid nanofiber dispersion prepared in 1) and 50 mg of PSS in a beaker, stir at a stirring speed of 300 r / min for 2 hours to obtain a uniform mixed liquid.

[0042] 3) The mixed solution obtained in step 2) is subjected to vacuum suction filtration, at room temperature, suction filtration for 12 hours, and dried at 60° C. for 4 hours to peel off to obtain an ANFs-PSS film with a film thickness of about 11 μm; the ANFs- The PSS film material is a two-dimensional layered structure, wherein the percentage content of PSS is 50.2wt%.

[0043] 4) Salt difference power generation performance test: ANFs-PSS membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com