Cement paste granulation quantification method

A technology of cement slurry and quantification method, which is applied in the direction of removing certain component weighing, measuring devices, instruments, etc., can solve the problems of agglomerated particle damage test, difficulty in achieving accuracy, inconvenient operation, etc., and achieve maintenance test Consistency, avoiding subjective errors, and stable test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

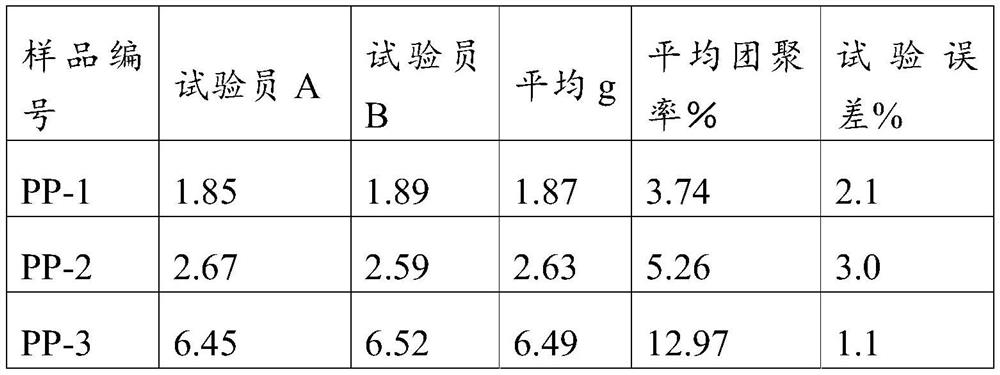

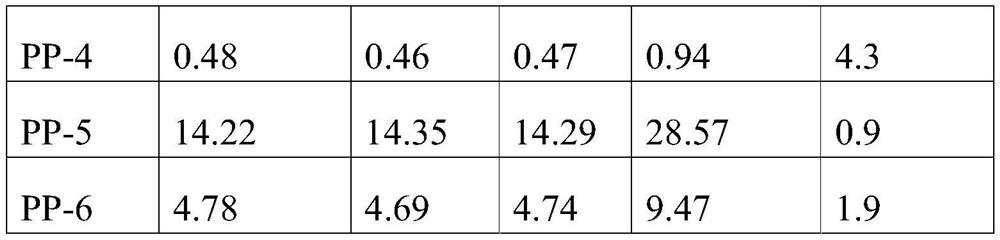

Examples

Embodiment 1

[0026] Take PP-1 cement, and the test process is carried out in sequence according to the following steps:

[0027] Use polyethylene preservative film to wrap the outside and bottom of the 250μm square hole screen, and fix the preservative film on the screen with 2 rubber bands, and the preservative film is close to the bottom of the screen.

[0028] Fully mix the 1kg sample of PP-1 cement after standing still, and weigh 50g with an electronic balance. Gently pour 50g of cement into the sieve, place the sieve on an adjustable amplitude and time vibrating sieving instrument, cover the sieve cover, use the vibrating sieve to vibrate the cement with an amplitude of 0.2mm for 1min, and discharge the air in the cement. Strain in a sieve.

[0029] Open the vibrating screen cover, use a beaker to take 1000ml of pure water with a water temperature of 20°C, make the edge of the beaker close to the edge of the screen, and pour the water into the screen gently to avoid water directly po...

Embodiment 2

[0038] Take PP-1 cement, and the test process is carried out in sequence according to the following steps:

[0039] Use polyethylene preservative film to wrap the outside and bottom of the 250μm square hole screen, and fix the preservative film on the screen with 2 rubber bands, and the preservative film is close to the bottom of the screen.

[0040] Fully mix the 1kg sample of PP-1 cement after standing still, and weigh 100g with an electronic balance. Gently pour 100g of cement into the sieve, place the sieve on an adjustable amplitude and time vibrating sieving instrument, cover the sieve cover, use the vibrating sieve to vibrate the cement with an amplitude of 0.5mm for 0.8min, and discharge the air in the cement. Spread out in a sieve.

[0041]Open the vibrating screen cover, use a beaker to take 1000ml of pure water with a water temperature of 20°C, make the edge of the beaker close to the edge of the screen, and pour the water into the screen gently to avoid water dire...

Embodiment 3

[0045] Take PP-1 cement, and the test process is carried out in sequence according to the following steps:

[0046] Use polyethylene preservative film to wrap the outside and bottom of the 250μm square hole screen, and fix the preservative film on the screen with 2 rubber bands, and the preservative film is close to the bottom of the screen.

[0047] Fully mix the 1kg sample of PP-1 cement after standing still, and weigh 80g with an electronic balance. Gently pour 80g of cement into the sieve, place the sieve on an adjustable amplitude and time vibration screening instrument, cover the sieve cover, use the vibrating sieve to vibrate the cement with an amplitude of 0.3mm for 2 minutes, and discharge the air in the cement. Strain through a sieve.

[0048] Open the vibrating screen cover, use a beaker to take 1000ml of pure water with a water temperature of 20°C, make the edge of the beaker close to the edge of the screen, and pour the water into the screen gently to avoid water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com