Stirring saw chain fatigue test device

A fatigue test and stirring technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of block jamming, manual adjustment of block position, low cutting efficiency, etc., to eliminate The effects of frequent shutdowns, improved test efficiency, and stable test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

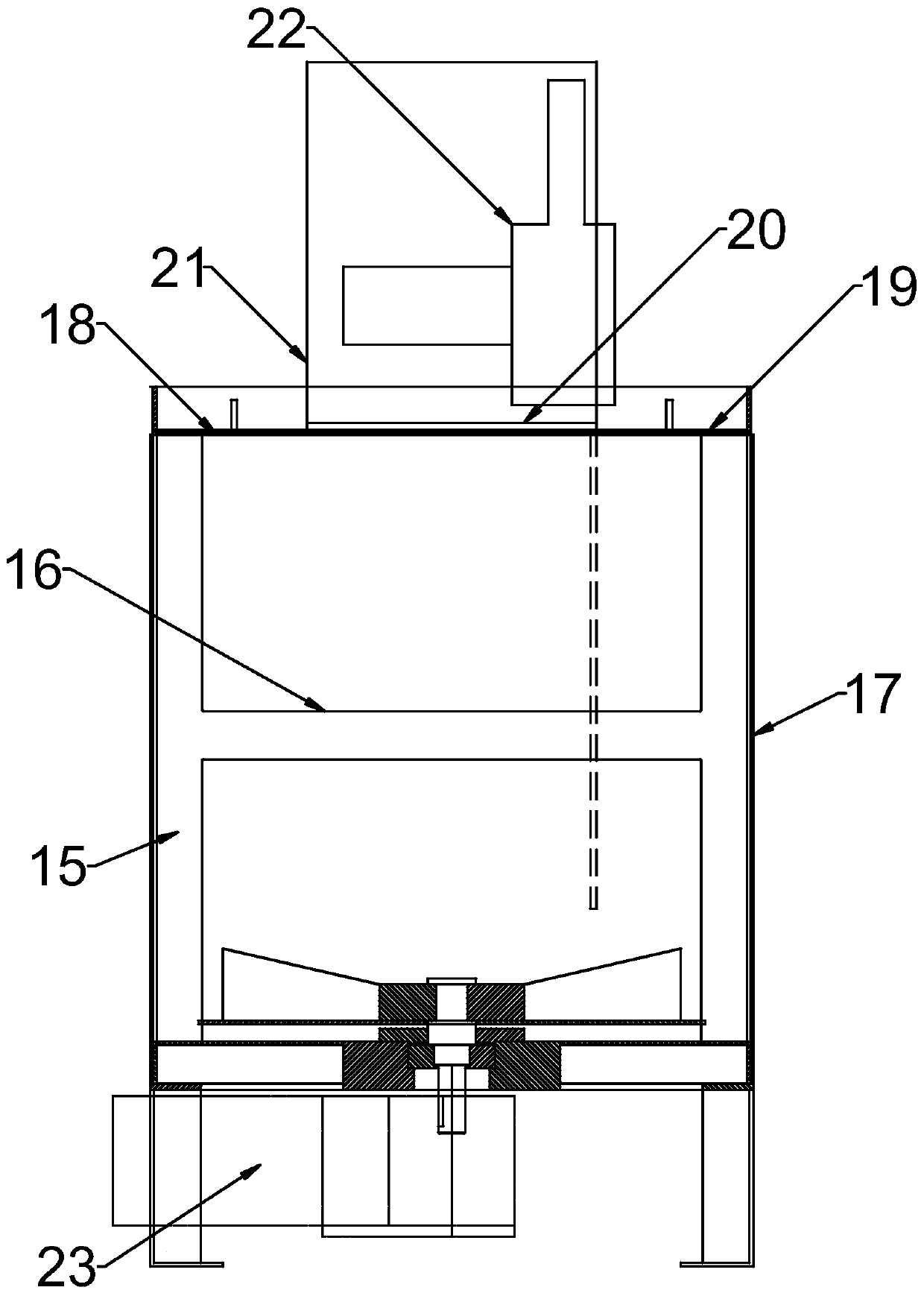

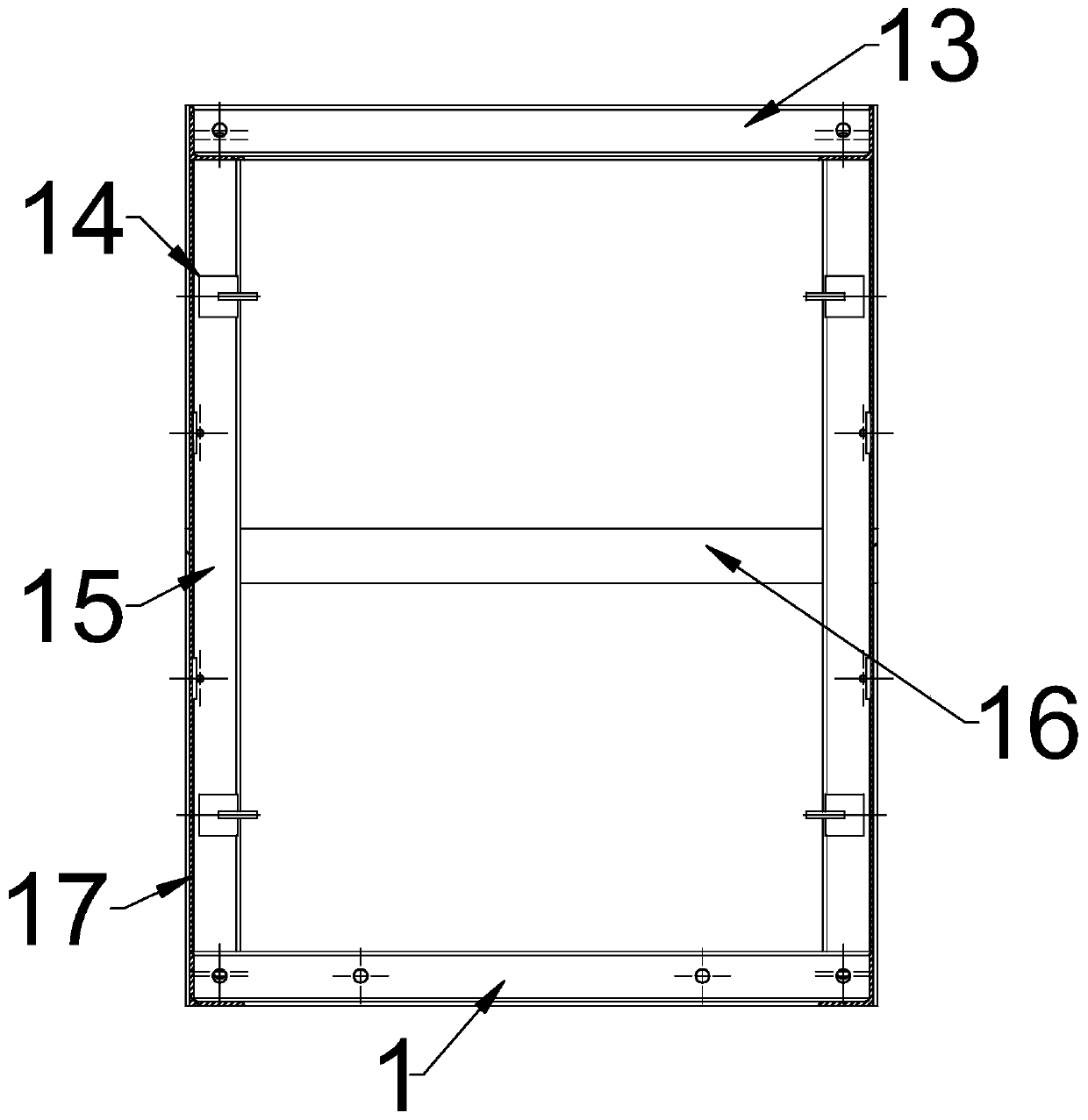

[0033] see Figure 1-9 , in an embodiment of the present invention, a stirring type saw chain fatigue test device includes a chassis, a box body, a box cover and a chainsaw 22, the box is filled with wood blocks, and the chainsaw 22 is inserted into the box. The chainsaw 22 is constantly sawing wood so that it is tested for fatigue.

[0034] The fatigue test device also includes a stirring mechanism driven by the motor 23, and the stirring mechanism is used to drive the block when the chain saw 22 is stuck in the process of sawing wood, so as to drive the block to shake, so as to overcome the blockage of the chain saw and the block The problem.

[0035] The underframe includes an underframe angle steel 1, an underframe channel steel 2, an underframe supporting plate 3, an underframe bearing block 4 and an underframe bearing 5, and the underframe angle steel 1, underframe channel steel 2, and underframe supporting plate 3 and the bottom frame bearing seat 4 are formed by weld...

Embodiment 2

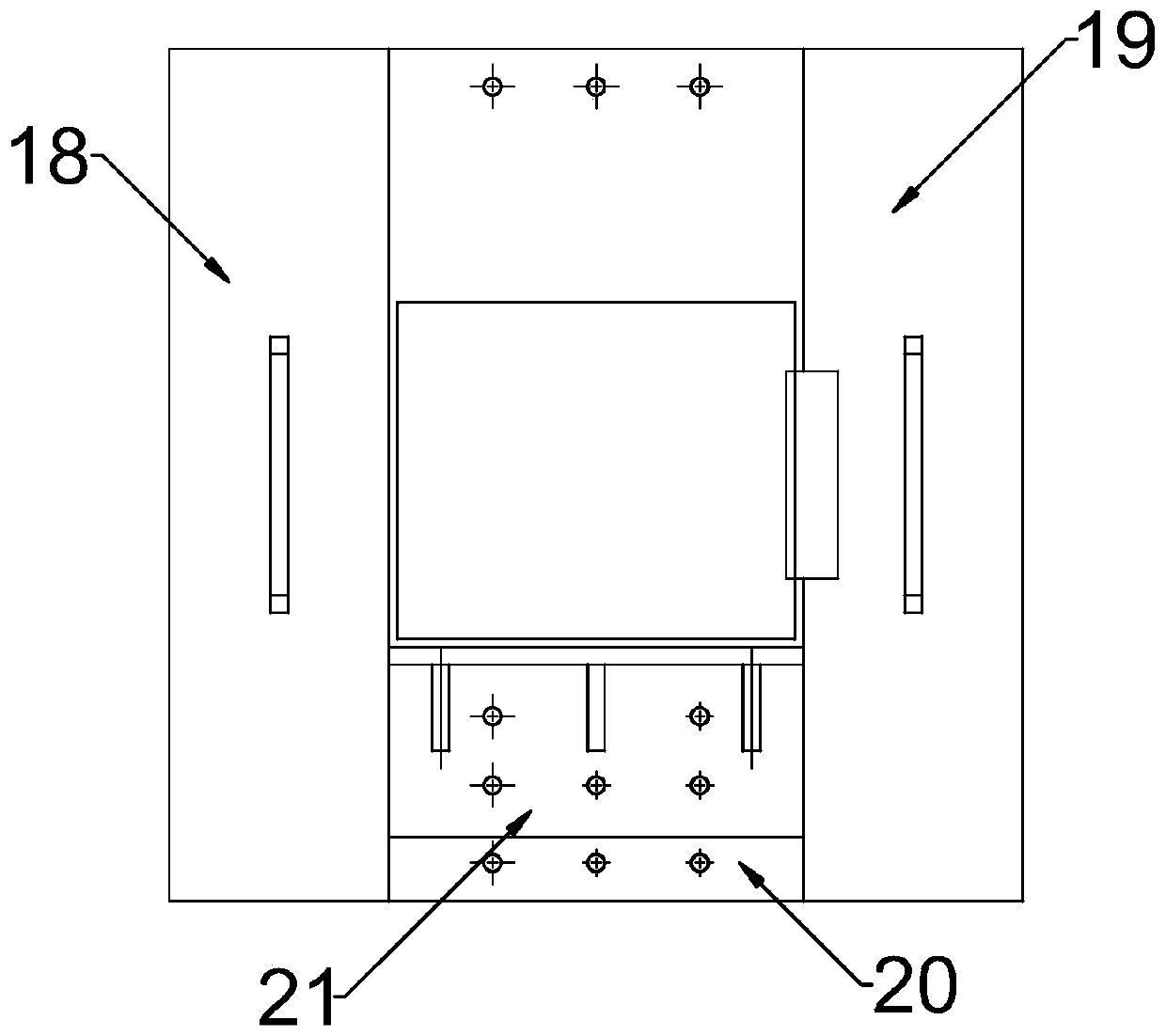

[0040] Please refer to the stirring shaft 10 in the figure, in the embodiment of the present invention, a stirring type saw chain fatigue test device, on the basis of embodiment 1, an electrical control system is also connected under the cover, and the electrical control system includes control button, programmable logic controller (PLC), analog-to-digital converter (A / D), speed governor and acceleration sensor, and the programmable controller and control button, analog-to-digital converter, speed governor and acceleration sensor are both By electrical connection, the control button and the speed governor are all electrically connected with the motor 23, and the programmable controller is used as the main control device to control the start / stop of the chain saw 22, the start / stop, speed regulation and operation of the motor 23. Forward and reverse control: the acceleration sensor is arranged on the support plate 21, and by performing real-time detection of the vibration accele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com