A sorting mechanism for building block parts

A technology of parts and building blocks, which is applied in the field of building block parts sorting mechanism, can solve the problems of high cost, unfavorable competition, unfavorable health of staff, and easy jamming machines, so as to eliminate frequent shutdown of jamming machines, widely use value, reduce Effects of Noise Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

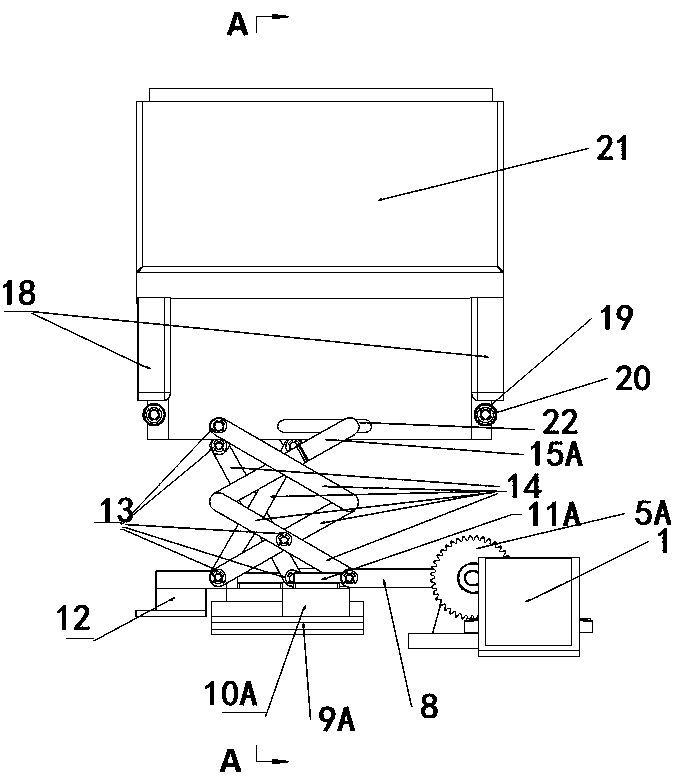

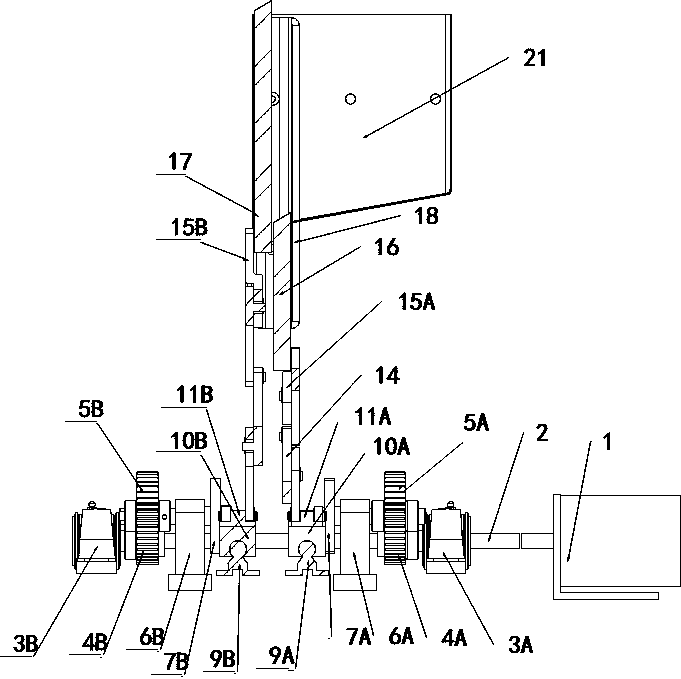

[0022] refer to figure 1 , figure 2 The overall structure schematic diagram of the present invention shown.

[0023] A sorting mechanism for building block parts in an embodiment of the present invention includes a transmission unit, two sets of scissor lifting units, a reciprocating push plate unit, and an inclined slotted parts box.

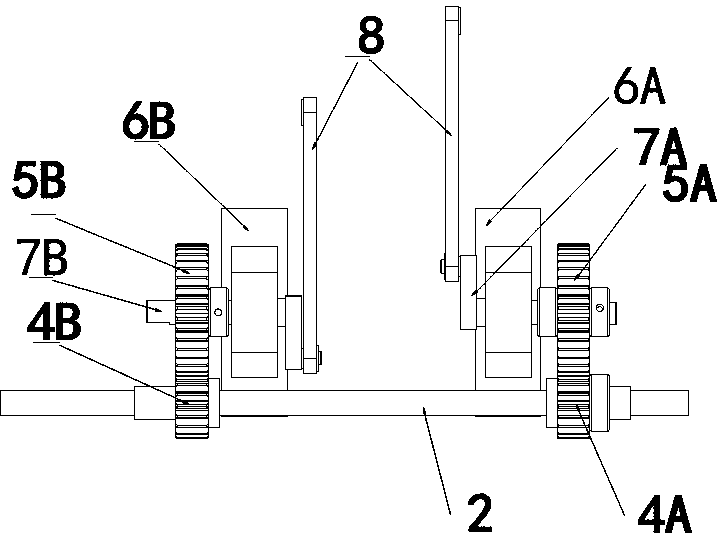

[0024] refer to figure 2 As shown in the structural diagram, the transmission unit consists of motor 1, transmission shaft 2, transmission shaft support 3A, 3B, pinion gear 4A, 4B, large gear 5A, 5B, semicircle turntable support 6A, 6B, two sets of turntables (semicircle turntable 7A, 7B), two sets of guide rods 8; the scissor lifting unit is composed of transmission slide rail 9, transmission slider 10, guide rod slider conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com