Method for screening electrolytic copper foil additive through density function theory

A technology of electrolytic copper foil and additives, which is applied in the direction of electrolytic process, electroforming, testing metal, etc., can solve the problems of inability to achieve high efficiency and effective screening of electrolytic copper foil additives, and achieve the effect of specific performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] A method for screening additives for electrolytic copper foil using density function theory,

[0063] The methods include:

[0064] 1) The Vienna Ab-initio Simulation Package was used to construct a unit cell model composed of several base atoms, and the generalized gradient approximation method of PBE (Perdew, Burke, and Ernzerhof) was used to calculate and obtain the exchange-correlation functional. In the constructed unit cell model Substrate atoms are used in projected growth (PAW) waves for electron-ion interactions, created in the adsorption direction (Z-axis direction) of the unit cell model the vacuum layer;

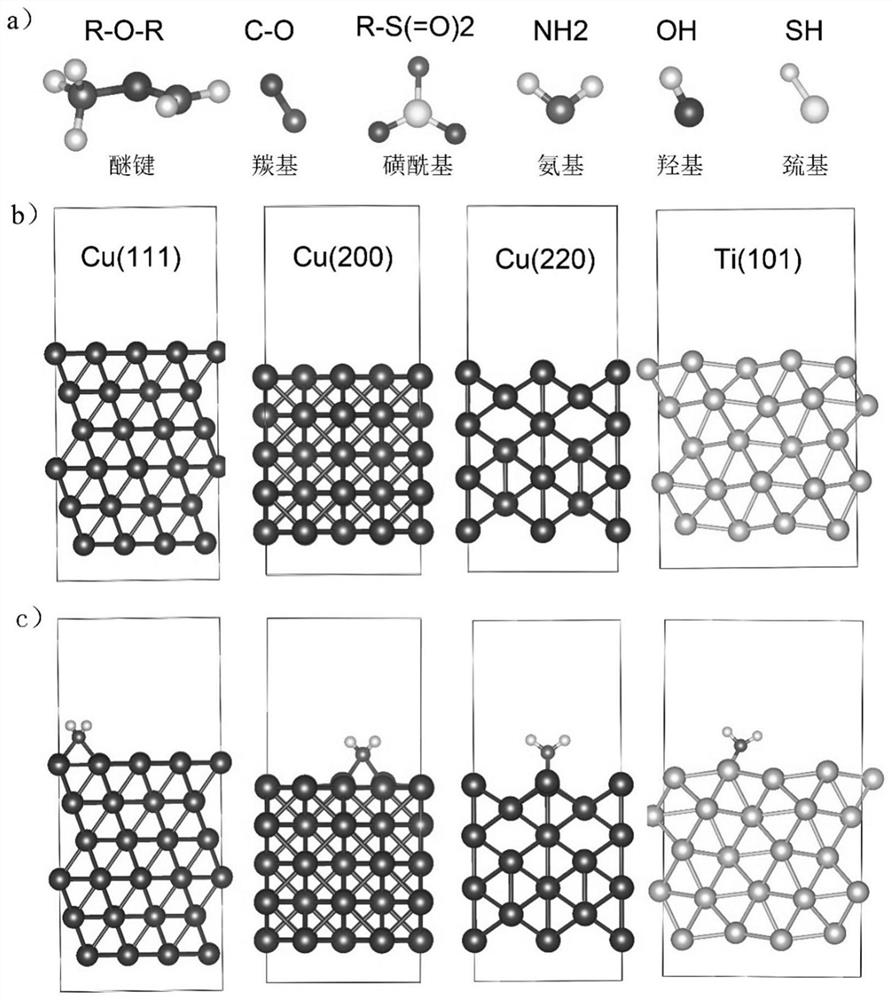

[0065] In this embodiment, the functional group selected in this step is as figure 1 As shown in (a), the constructed unit cell model is as follows figure 1 As shown in (b), the adsorption surfaces of the functional groups of the constructed unit cell are Cu(111), Cu(200), Cu(220) and Ti(101) from left to right, while the functional groups for computat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com