Method and device for treating nitrate-containing waste liquid

A technology of treatment device and treatment method, applied in water/sewage treatment, chemical instruments and methods, water/sewage treatment equipment, etc., can solve the problem of low chemical reaction efficiency, limited reaction area, and inability to be used for industrial nitrate waste liquid treatment and other problems, to achieve the effect of wide application scope, obvious environmental improvement, reduction of labor intensity and occupational diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

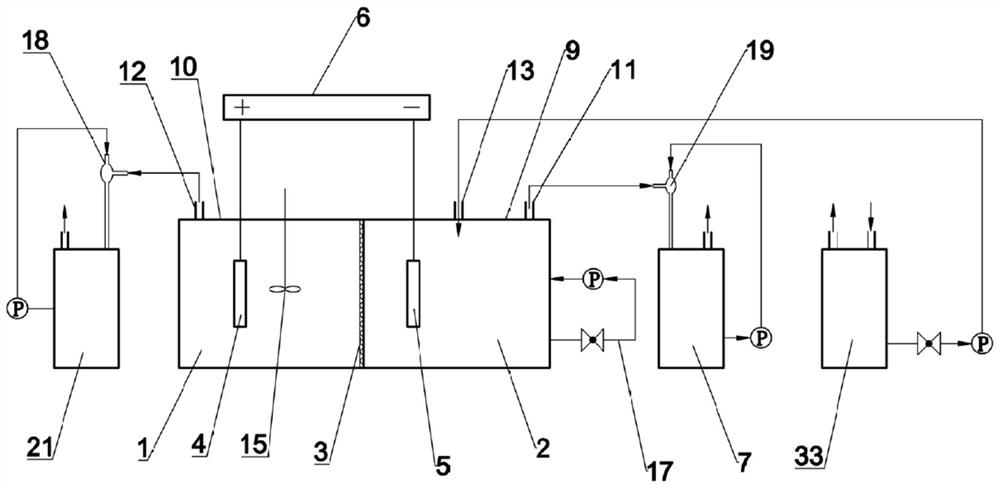

[0067] like figure 1 As shown, the nitrate-containing waste liquid treatment device of embodiment 1 includes an electrolytic separator 3, an electrolytic reaction tank separated by an electrolytic separator 3 into an anode zone 1 and a cathode zone 2, an electrolytic anode 4, an electrolytic cathode 5, and an electrolytic power supply 6. The first nitrogen oxide gas treatment device 7 . The electrolysis separator 3 is a bipolar membrane; the electrolysis power supply 6 is a pulsed electrolysis power supply; the first nitrogen oxide gas treatment device 7 is a nitrogen oxide high-temperature reduction treatment device. The electrolysis anode 4 is located in the anode area 1 and is connected to the positive pole of the electrolysis power supply 6 , and the electrolysis cathode 5 is located in the cathode area 2 and is connected to the negative pole of the electrolysis power supply 6 . The top of the cathode area 2 is provided with a first cover plate 9 , and the first cover pla...

Embodiment 2

[0075] like figure 2 As shown, the nitrate-containing waste liquid treatment device of embodiment 2 includes an electrolytic separator 3, an electrolytic reaction tank separated by an electrolytic separator 3 into an anode zone 1 and a cathode zone 2, an electrolytic anode 4, an electrolytic cathode 5, and an electrolytic power supply 6. The first nitrogen oxide gas treatment device 7, the catholyte preparation tank 24, the first transfer tank 25, the second transfer tank 26, the first replenisher storage tank 27, the water-oil separator 22, the first solid-liquid separation Device 23. The electrolysis separator 3 is a cationic membrane; the electrolysis power supply 6 is a pulsed electrolysis power supply; the first nitrogen oxide gas treatment device 7 is a nitrogen oxide high-temperature reduction treatment device. The electrolysis anode 4 is located in the anode area 1 and is connected to the positive pole of the electrolysis power supply 6 , and the electrolysis cathode...

Embodiment 3

[0086] like image 3 As shown, the nitrate-containing waste liquid treatment device of embodiment 3 includes an electrolytic separator 3, an electrolytic reaction tank separated by an electrolytic separator 3 into an anode zone 1 and a cathode zone 2, an electrolytic anode 4, an electrolytic cathode 5, and an electrolytic power supply 6. The first nitrogen oxide gas treatment device 7 , the tail gas treatment device 21 , and the waste liquid pretreatment tank 33 . The electrolytic separator 3 is a cation exchange membrane; the first nitrogen oxide gas processing device 7 is a normal temperature chemical reaction processing device for nitrogen oxide gas. The electrolysis anode 4 is located in the anode area 1 and is connected to the positive pole of the electrolysis power supply 6 , and the electrolysis cathode 5 is located in the cathode area 2 and is connected to the negative pole of the electrolysis power supply 6 . A first cover plate 9 is provided on the top of the cathod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com