Rapid and reliable heat conduction material separating mechanism

A heat-conducting material and separation mechanism technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient separation, mutual adhesion, etc., achieve the effect of easy operation, reduce material waste, and improve the success rate of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

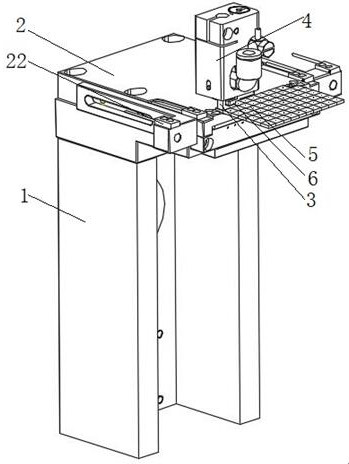

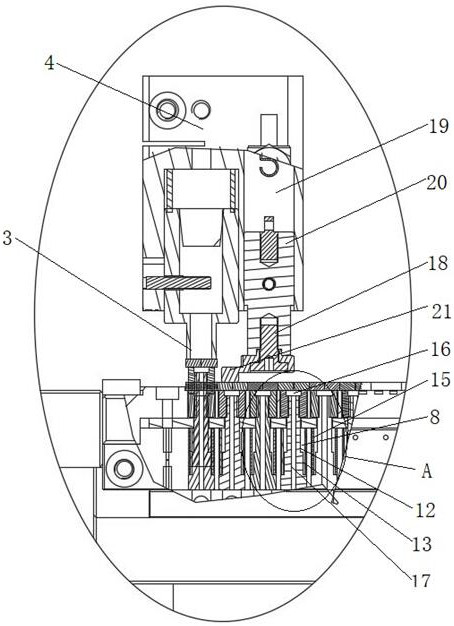

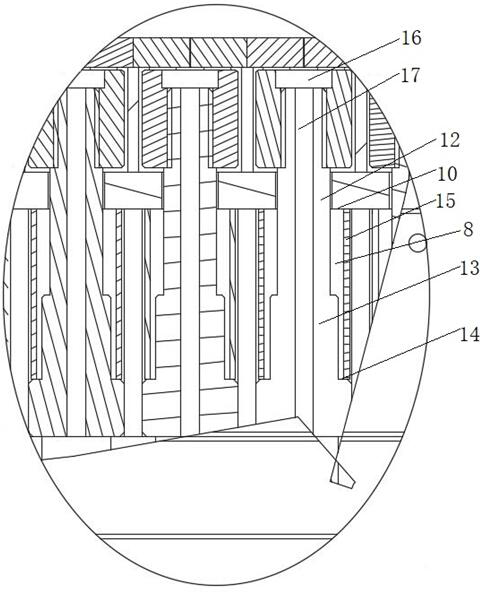

[0022] Such as figure 1 and figure 2 Shown is a fast and reliable heat-conducting material separation mechanism disclosed in the present invention, including a base 1, a bid holder 2, an elastic movable suction nozzle 3 and a suction nozzle holder 4, the bid holder 2 is arranged on the base 1, and the bid holder The seat 2 is provided with an opposite-firing optical fiber 22 for detecting the position of the material at the feeding place of the heat-conducting material. The elastic movable suction nozzle 3 is located above the bid holder 2. The suction nozzle seat 4 cooperates with the manipulator, and the elastic movable suction nozzle 3 is facing The upper surface of the bearing seat 2 is used to absorb the heat-conducting material 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com