Anti-residue reaming forming device suitable for flange machining

A forming device and flange technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of unfavorable iron scrap collection, affecting the use efficiency of drill bits, affecting the positioning of laser pointers, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

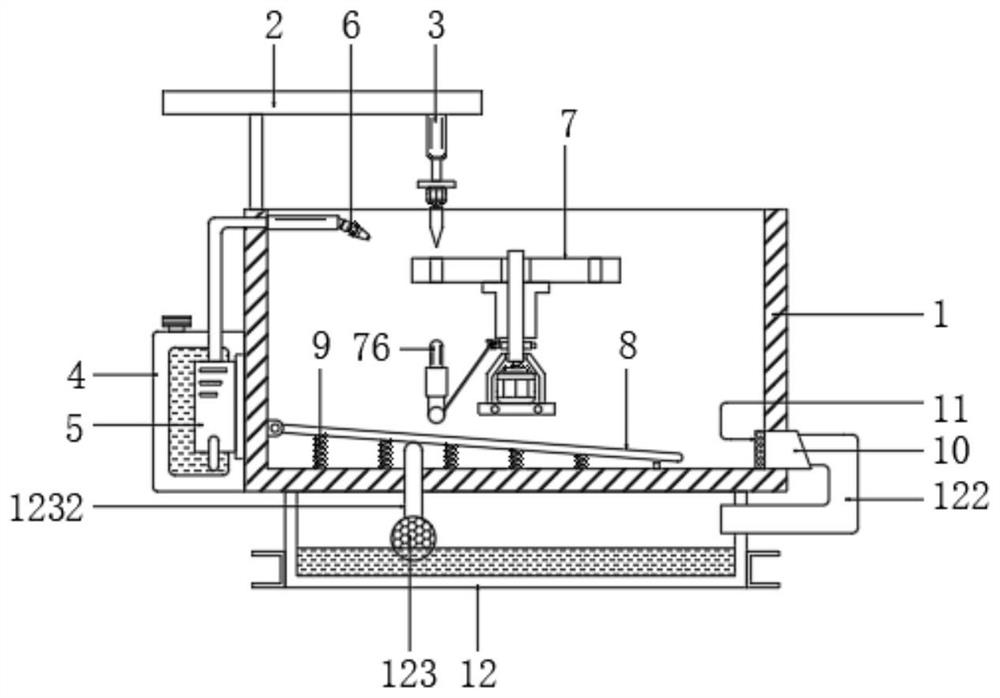

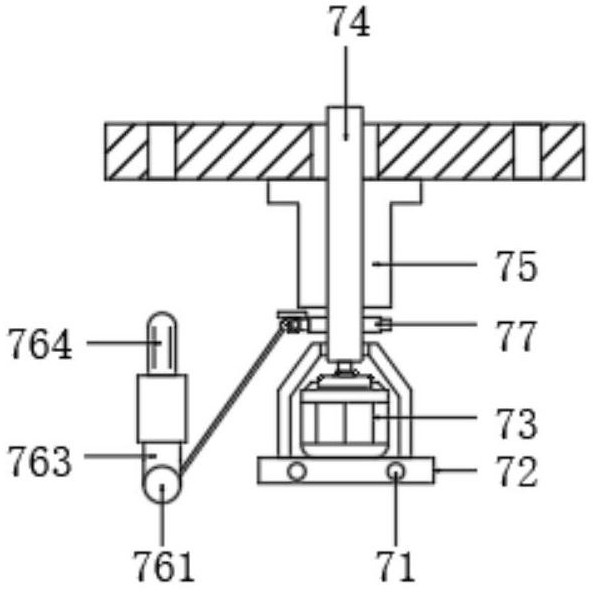

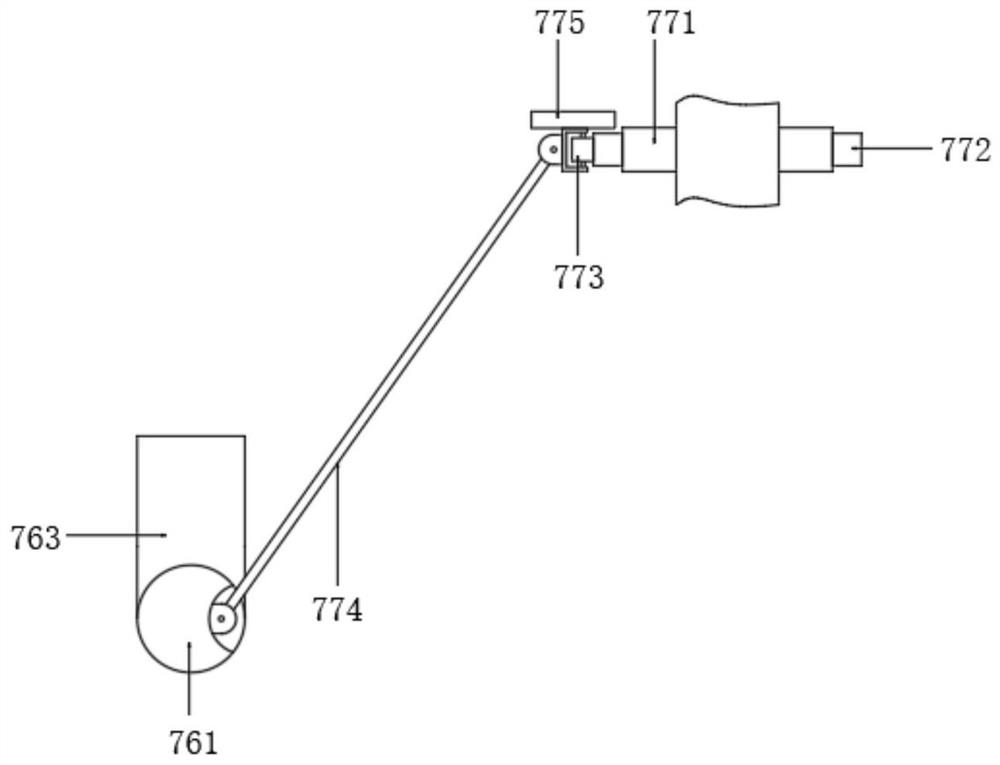

[0022] Anti-residue reaming forming unit for flange machining, see figure 1 and Figure 6 , comprising a protective groove 1, the top left side of the protective groove 1 is provided with a mounting frame 2, the bottom of the mounting frame 2 is connected with a reamer 3, the reamer 3 is the same as the prior art, and it includes a mounting frame 2 Electric push rod, the power end of the electric push rod is connected to the drive motor, and the power end of the drive motor is connected to the drill bit. The left bottom of the protective tank 1 is provided with a clean water tank 4 and a water pump 5 in sequence from back to front. The water inlet of the water pump 5 is connected to the clean water The tank 4 is connected, the water outlet of the water pump 5 is connected with the nozzle 6, the nozzle 6 is located on the top of the inner wall on the left side of the protective tank 1, the inner wall of the protective tank 1 is provided with an auxiliary mechanism 7, and the bo...

Embodiment 2

[0025] Anti-residue reaming forming unit for flange machining, see figure 1 and figure 2 , including a protective tank 1, the top left side of the protective tank 1 is provided with a mounting frame 2, the bottom of the mounting frame 2 is connected with the reamer 3, and the left bottom of the protective tank 1 is sequentially provided with a clean water tank 4 and a water pump from back to front 5. The water inlet of the water pump 5 is connected to the clean water tank 4, and the water outlet of the water pump 5 is connected to the nozzle 6. The nozzle 6 is located on the top of the inner wall on the left side of the protective tank 1. The inner wall of the protective tank 1 is provided with an auxiliary mechanism 7. The protective tank 1 The bottom of the inner wall on the left side is hinged with a slant plate 8, and the bottom of the slant plate 8 is uniformly provided with a spring 9, and the bottom of the spring 9 is connected to the bottom inner wall of the protectio...

Embodiment 3

[0029] Anti-residue reaming forming unit for flange machining, see Figure 1 to Figure 5, including a protective tank 1, the top left side of the protective tank 1 is provided with a mounting frame 2, the bottom of the mounting frame 2 is connected with the reamer 3, and the left bottom of the protective tank 1 is sequentially provided with a clean water tank 4 and a water pump from back to front 5. The water inlet of the water pump 5 is connected to the clean water tank 4, and the water outlet of the water pump 5 is connected to the nozzle 6. The nozzle 6 is located on the top of the inner wall on the left side of the protective tank 1. The inner wall of the protective tank 1 is provided with an auxiliary mechanism 7. The protective tank 1 The bottom of the inner wall on the left side is hinged with a slant plate 8, and the bottom of the slant plate 8 is uniformly provided with a spring 9, and the bottom of the spring 9 is connected to the bottom inner wall of the protection g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com