Supporting base of lathe for two-end-face floating positioning of machined part and using method thereof

A technology of workpiece and floating positioning, which is applied in the direction of metal processing machinery parts, positioning devices, metal processing equipment, etc., can solve the problems of obvious vibration knife lines, high production cost, and affect the surface quality of parts, so as to achieve the disappearance of vibration knife lines , the effect of meeting the processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in further detail below in conjunction with accompanying drawing:

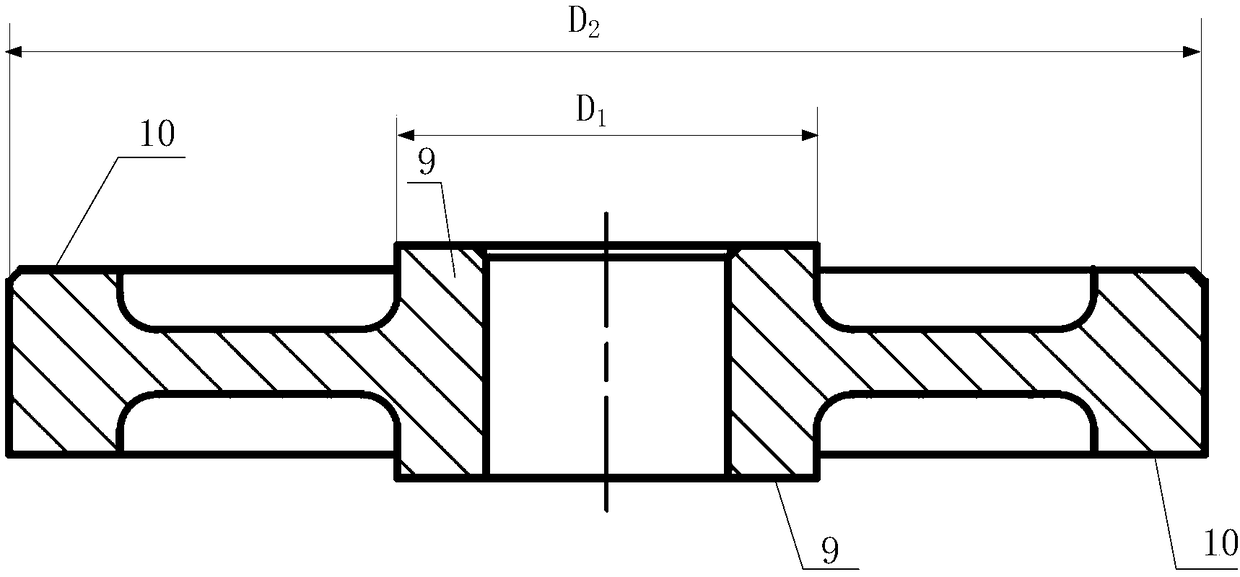

[0038] see figure 1 , the workpiece 20 of the present invention is a special-shaped part, and the special-shaped part is a part whose diameter ratio between the second and first end faces is greater than 3. In this embodiment, it is a gear, and the second end face 10 is a tooth portion close to the gear on the two end faces The first end surface 9 is a support surface close to the gear axis on both end surfaces; the first end surface 9 and the second end surface 10 have a height difference within a certain range; the diameter of the second end surface 10 is D 2 , the diameter of the first end face 9 is D 1 ,D 2 / D 1 >3; In this embodiment, both ends of the gear are provided with weight-reducing grooves.

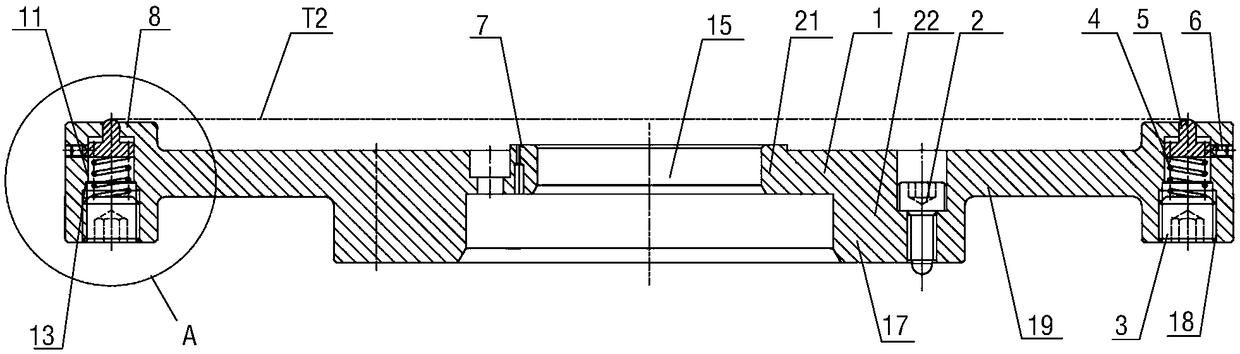

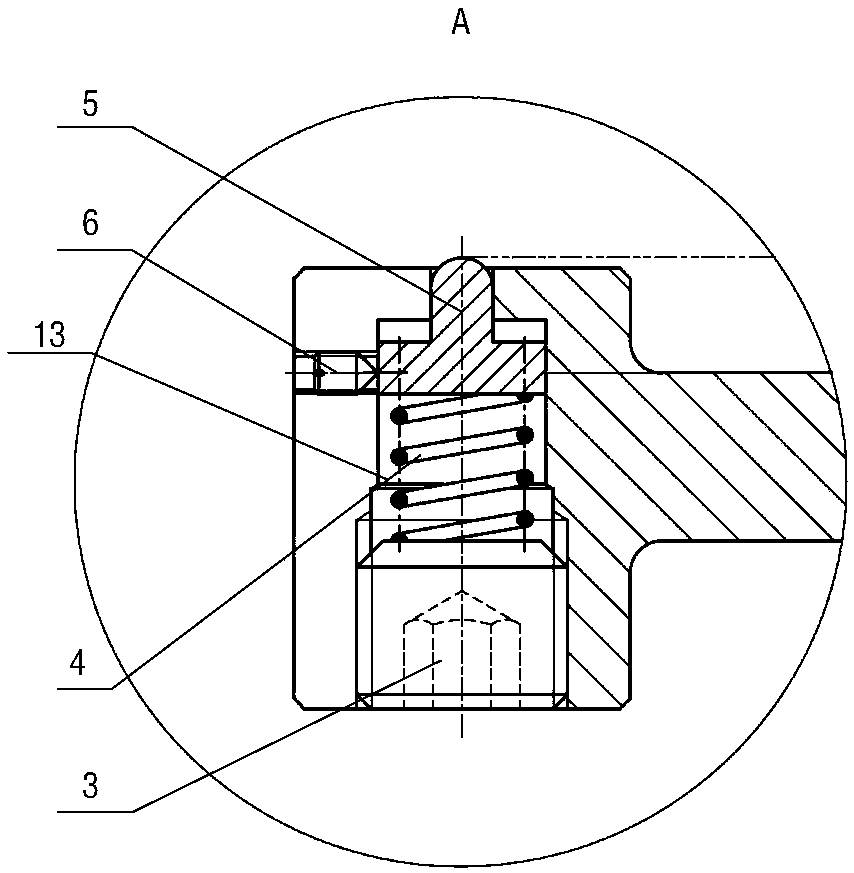

[0039] see figure 2 with image 3, the support seat entity 1 of the present invention includes a mounting hole 15, an inner ring 17 and an outer ring 18; the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com