Coupling arrangement for workpiece-taking of plastic jetting-moulding machine

A technology of connecting device and injection molding machine, applied in the direction of joints, manipulators, manufacturing tools, etc., can solve the problems of inability to adjust the longitudinal position of the longitudinal rod, poor stability, restrictions and other problems, and achieve the effect of improving work flexibility and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

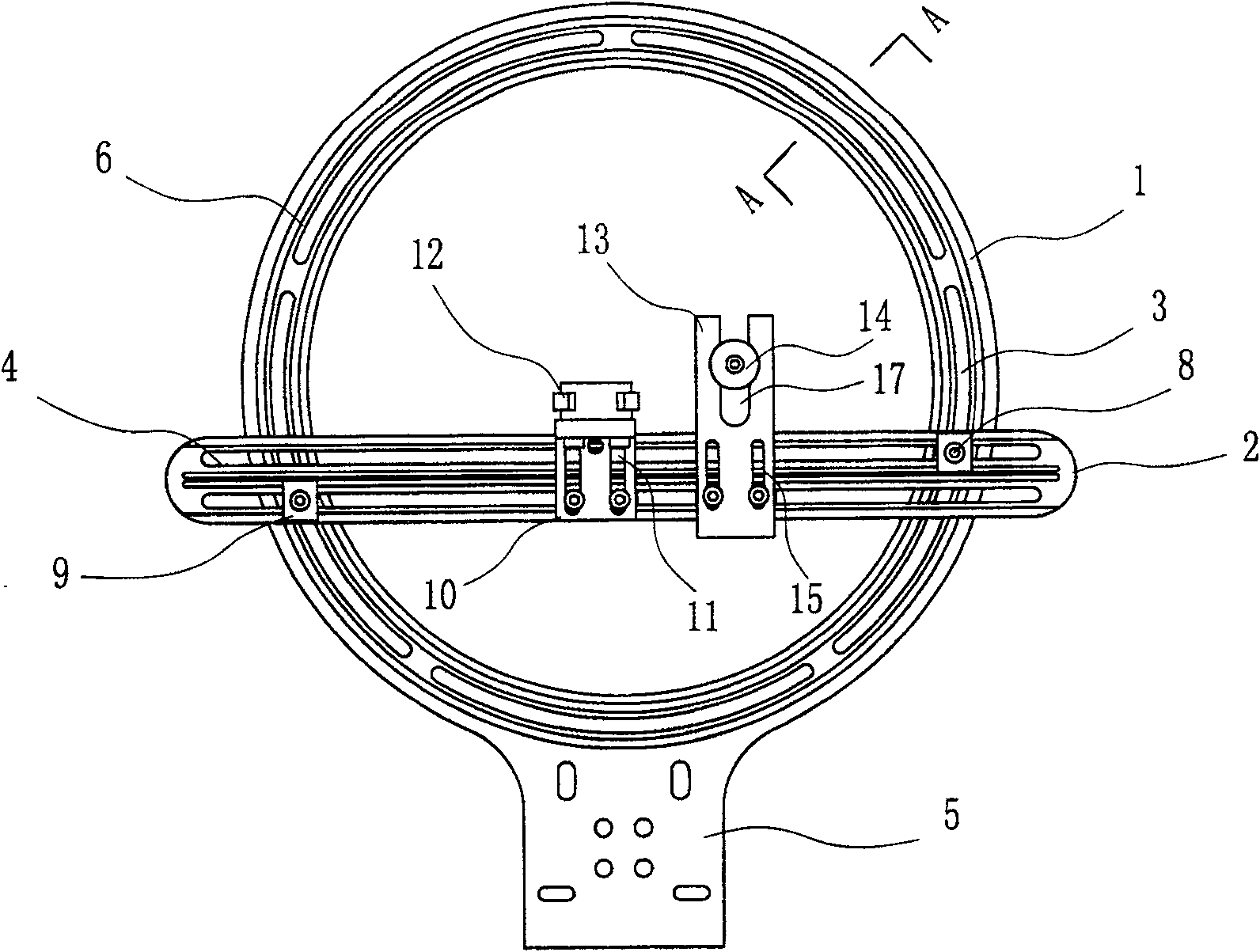

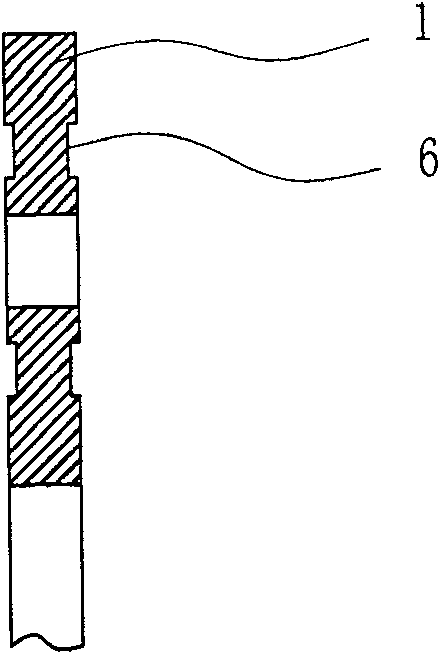

[0023] Embodiment one: see attached figure 1 To attach Figure 4 As shown, a connecting device for picking up parts from an injection molding machine includes a ring-shaped support 1 and a transverse support 2. The lower end of the ring-shaped support is provided with a connecting part 5 for the fixed connection between the connecting device and the manipulator. , there are 5 installation holes 3 evenly distributed intermittently along the ring edge of the ring-shaped bracket, and the horizontal bracket is provided with 2 slideway holes 4 arranged in parallel for sliding and positioning of the pick-up mechanism. The left end of the horizontal bracket passes through the slideway The holes are fixed with the ring bracket through bolts 8 and nuts 9, and the right end is fixed with the ring bracket 1 through the bolts and nuts through the hole of the upper slideway. figure 1 As shown; on both sides of the ring bracket 1 and the transverse bracket 2, fixing grooves 6 are respectiv...

Embodiment 2

[0025] Embodiment two: see attached Figure 5 As shown, a connection device for picking up parts from an injection molding machine includes a hexagonal ring bracket and 2 transverse brackets. The right side of the ring bracket is provided with a connecting part for the fixed connection between the connection device and the manipulator. There are 6 installation holes evenly distributed intermittently along the edge of the ring-shaped bracket, corresponding to each ring-shaped edge, and each of the horizontal brackets is provided with 2 slideway holes arranged in parallel for the sliding of the pick-up mechanism. The cooperating and fixed connection of installation channel, slideway hole and bolt nut, wherein 1 clamp is installed on the left lateral support, and 2 clamps 18 are installed on the right lateral support, for the needs of pick-up station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com