Fully automatic butted system of electrode and method through mechanical arm

A robotic arm, fully automatic technology, applied in electric vehicles, current collectors, electrical components, etc., can solve the problems of long time, limiting the rapid popularization of electric vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

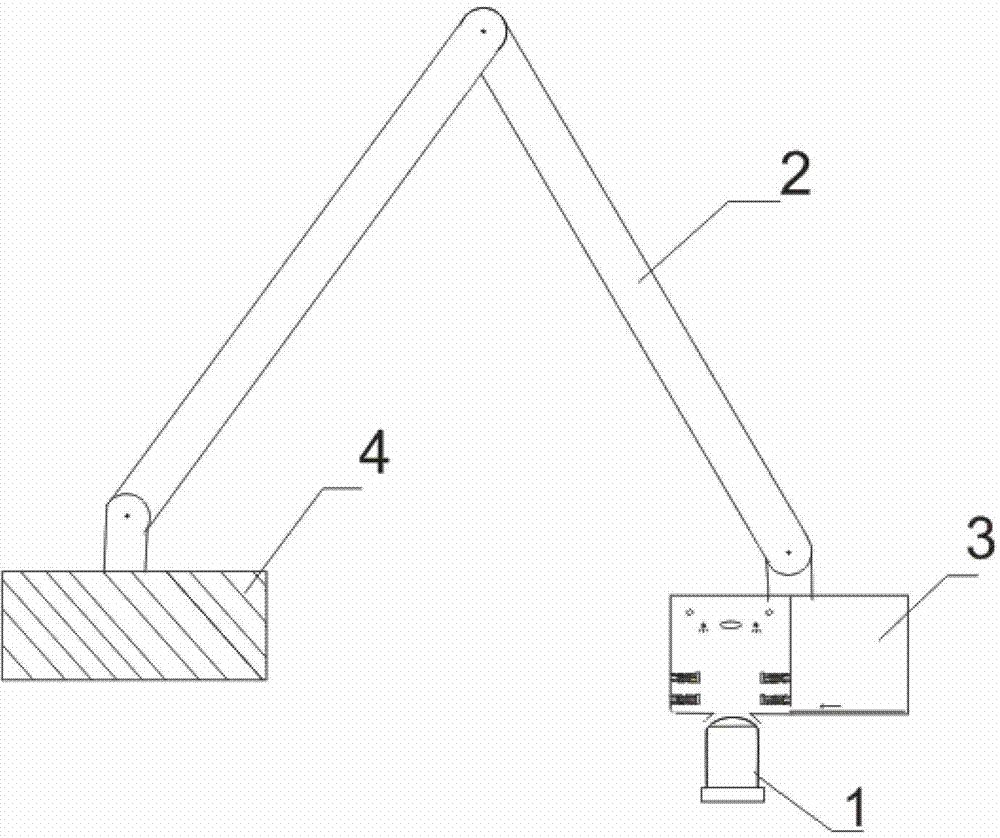

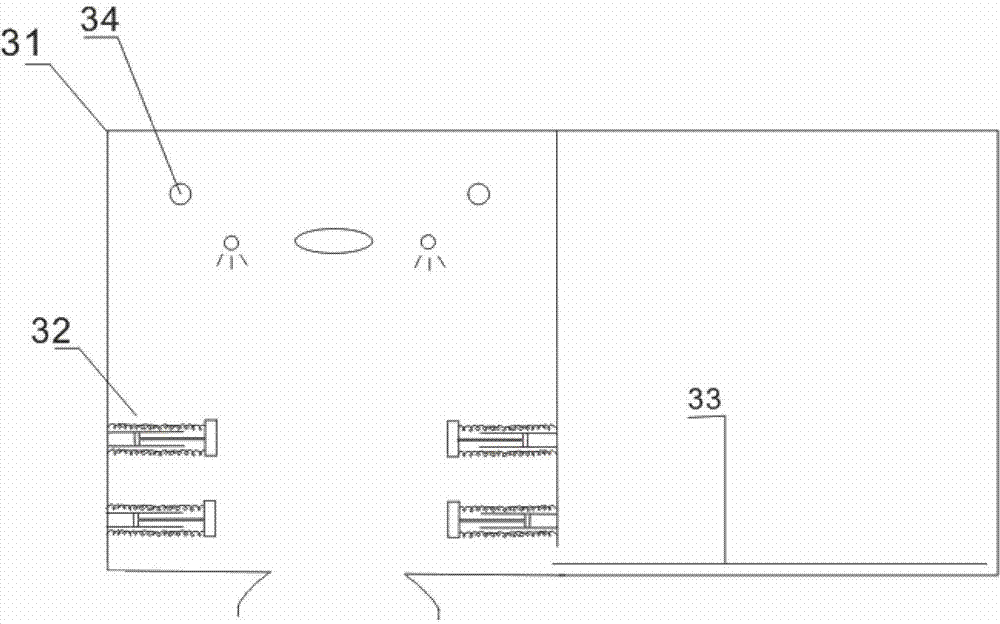

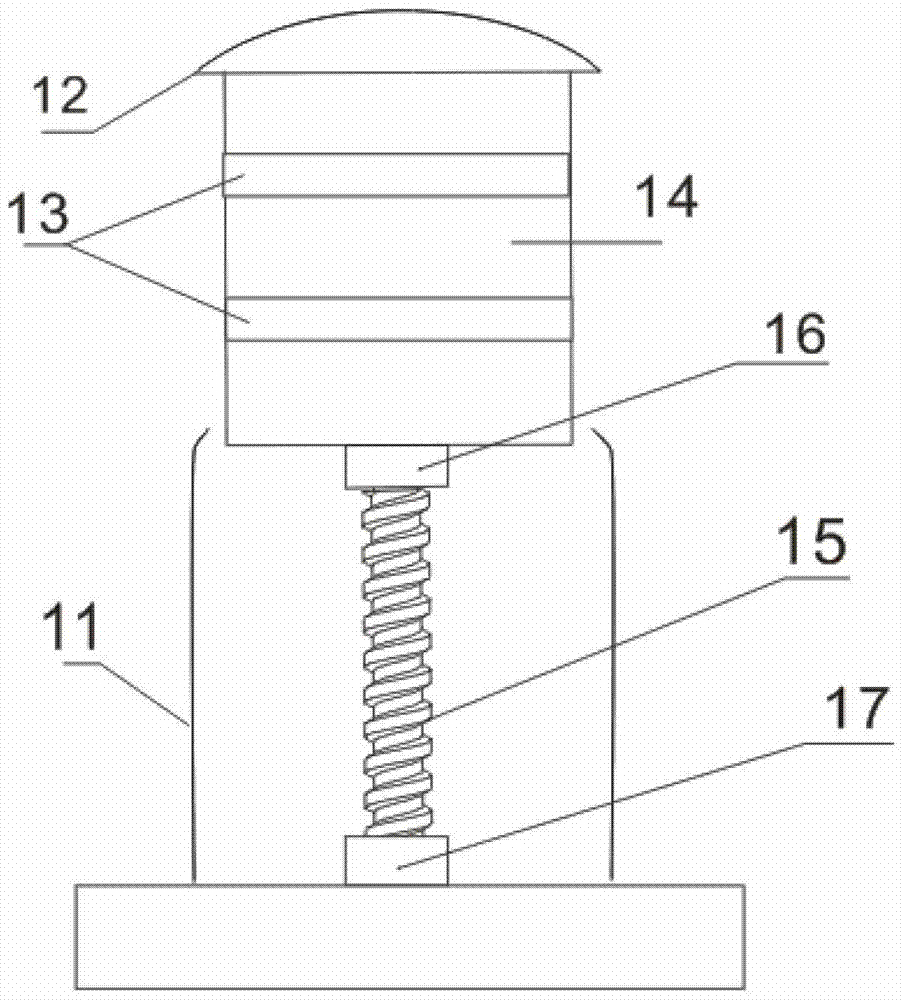

[0048] as attached figure 1 As shown, it includes a vehicle-mounted plug device 1, a mechanical arm 2, a charging pile socket device 3 and its control system. One end of the mechanical arm 2 is connected to the charging pile 4, and the other end is connected to the charging pile socket device 3. The joint of the mechanical arm 2 is An angular displacement sensor is installed on the top, and the action of the mechanical arm 2 is controlled by the control system. The angular displacement sensor is used to help the control system to grasp the attitude of the mechanical arm 2. The vehicle plug device 1 communicates with the control system through a wireless communication system. To achieve wireless communication, the charging pile socket device 3 is provided with an image recognition and positioning system, and the image recognition and positioning system is used to help the control system adjust the mechanical arm 2, thereby driving the charging pile socket device 3 to realize doc...

Embodiment 2

[0069] Embodiment 2: A method for fully automatic docking of electrodes through a mechanical arm, comprising the following steps:

[0070] 1. The driver operates the relevant buttons in the car to confirm the start of the charging task. The on-board plug device first sends a wireless signal to the charging pile to request charging. The charging pile will prepare according to the relevant information and maintain communication between the two parties after receiving the signal.

[0071] 2. With the help of the ultrasonic positioning system, the control system makes the charging pile socket device close to the vehicle plug device by controlling the motors of each joint of the robotic arm. Generally, it moves to the top of the vehicle plug device first, and then slowly moves from top to bottom. near.

[0072] 3. When the charging pile socket device is very close to the vehicle plug device, the blower is started, the movable cover of the charging pile socket device is opened, and ...

Embodiment 3

[0081] as attached Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the mechanical arm 2 is installed between the vehicle body 5 and the vehicle plug device 1 , while the charging pile socket device 3 is directly installed on the charging pile 4 .

[0082] A system for fully automatic docking of electrodes through a mechanical arm in this embodiment includes a vehicle-mounted plug device, a mechanical arm, a charging pile socket device and a control system thereof, one end of the mechanical arm is connected to the vehicle body, and the other end is connected to the vehicle-mounted plug device. An angular displacement sensor is installed on the joint of the mechanical arm, and the movement of the mechanical arm is controlled by the control system. The angular displacement sensor is used to help the control system to grasp the posture of the mechanical arm. Realize wireless connection with the control system, the charging pile socket device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com