Spray head welding positioning tool for spray ring

A technology for welding positioning tooling and nozzles, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the nozzles are not easy to ensure the same angle of the nozzles, achieve angle consistency, ensure welding quality, and facilitate the The effect of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

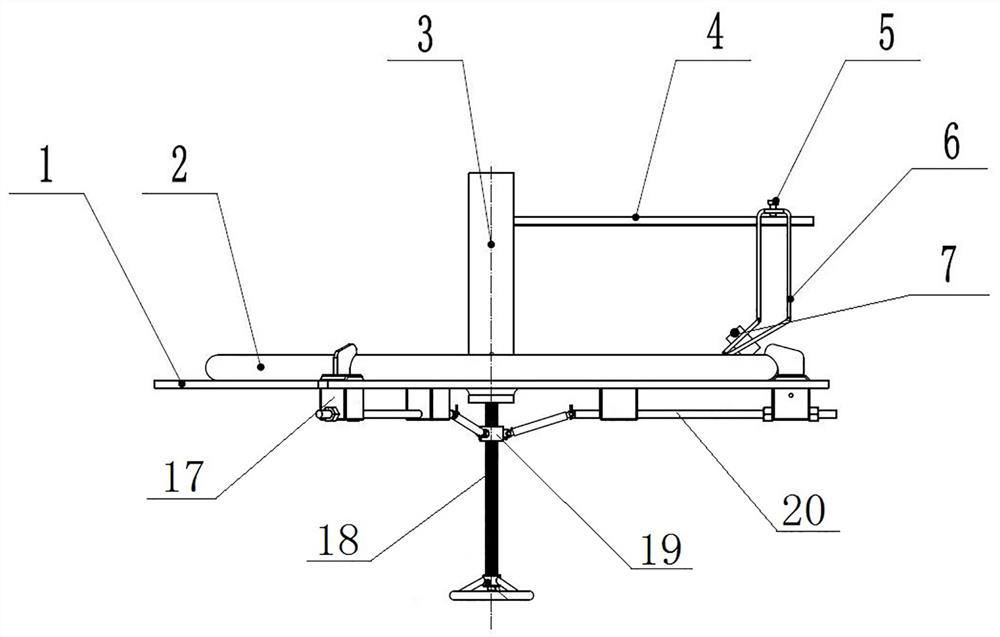

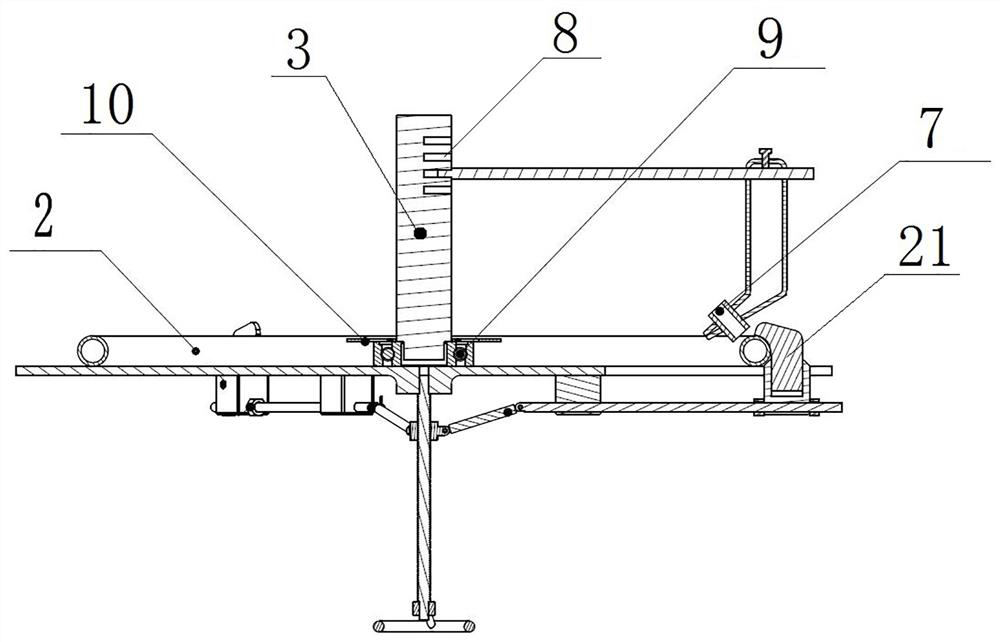

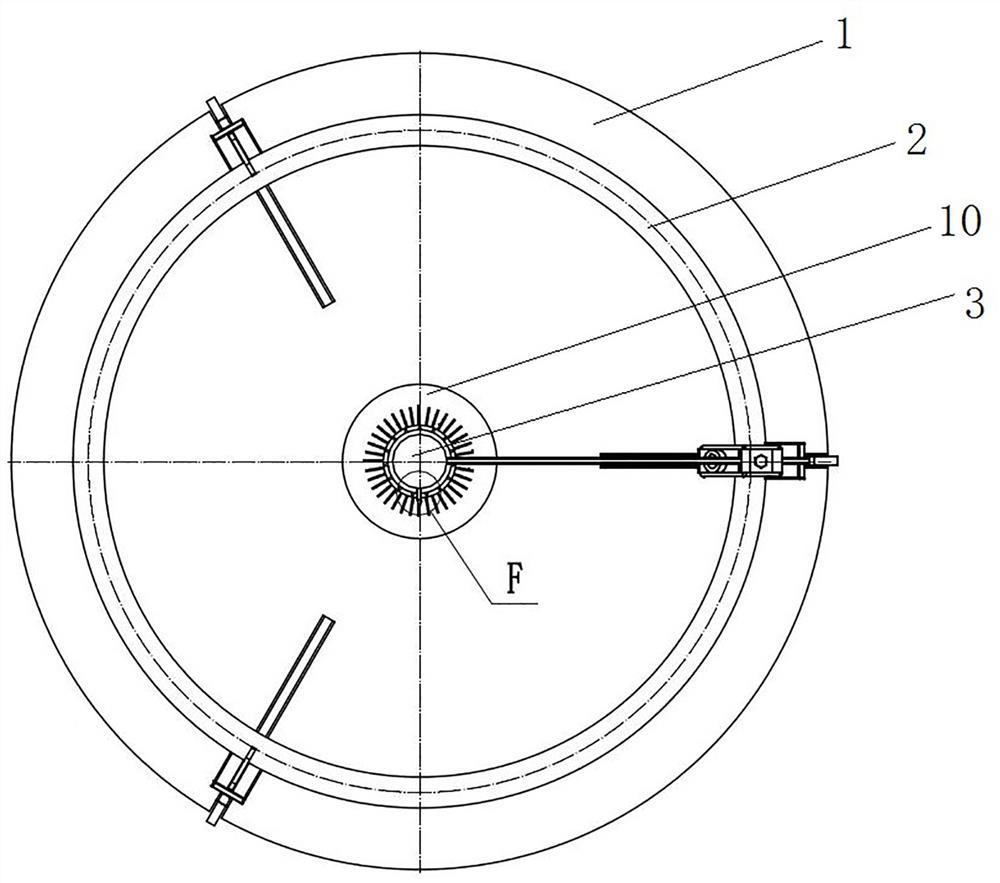

[0033] Embodiment 1 of the nozzle welding positioning frock of the spray ring in the present invention, as figure 1 As shown, the nozzle welding positioning tool is used to position the nozzle 7, so as to weld and fix multiple nozzles 7 on the spray ring 2 according to the same inclination angle.

[0034] Specifically, the spray head welding positioning tool in the present invention includes a base 1 for positioning and placing the spray ring 2. The base 1 has a support plane for carrying the spray ring 2. The spray ring 2 is placed horizontally on the support plane of the base 1. The base 1 It has a radial direction of the base and a central axis of the base corresponding to the radial direction of the spray ring and the central axis of the spray ring.

[0035] In order to position the nozzles 7 to be welded so that the nozzles 7 finally welded on the spray ring 2 have the same inclination angle, the base 1 is provided with a swivel frame 3, and the swivel frame 3 is pluggabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com