Chlorine-doped catalyst and preparation method and application thereof

A catalyst and chlorine doping technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex catalyst preparation process, unfavorable catalyst recovery, large catalyst dosage, etc., and achieve improvement effect, increase the degradation rate, and the effect of efficient degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

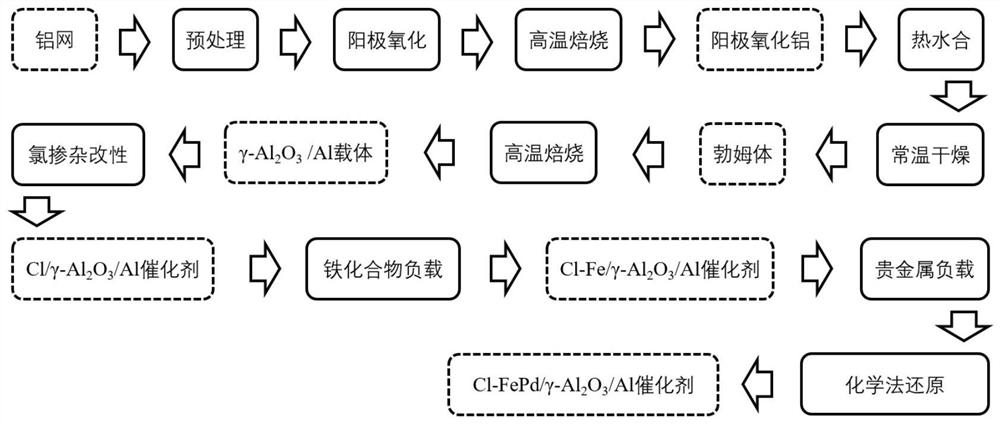

[0047] A preparation method of chlorine-doped catalyst:

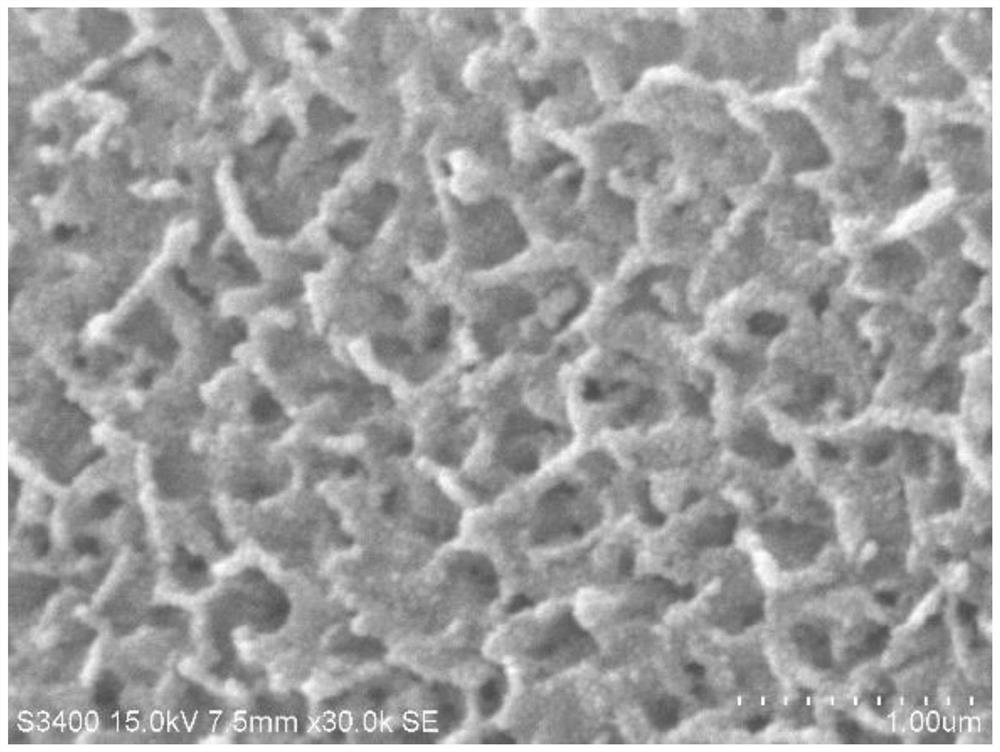

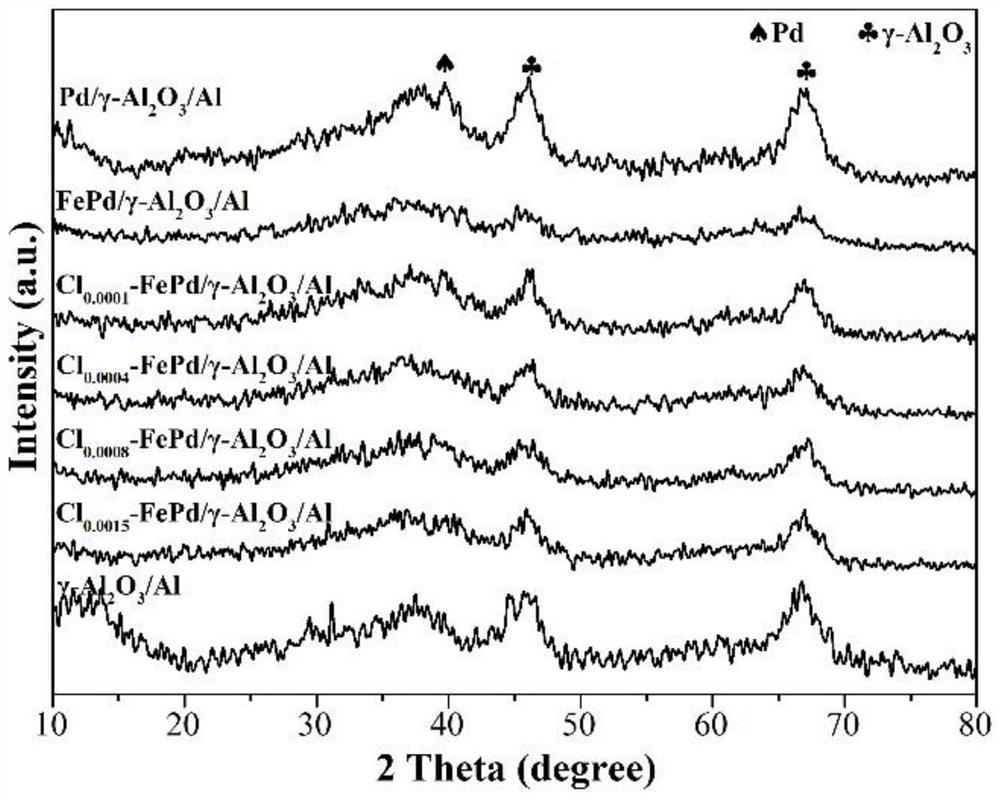

[0048] (1) Preparation of metal-based carrier: After soaking the aluminum mesh in 10wt% NaOH solution for 4min, and then soaking it in 10wt% HNO 3 Soak in the solution for 2 minutes to obtain the pretreated aluminum mesh, and place the pretreated aluminum mesh at a temperature of 20°C and a current density of 25A / m 2 The electrolyte is 0.4mol / L oxalic acid solution for 10h of anodic oxidation, then air-dried naturally, and then roasted at 350°C for 1h to obtain anodized aluminum, and the anodized aluminum was thermally hydrated in 80°C deionized water for 60min, at room temperature After drying at low temperature, the hydroxyl-rich boehmite (AlOOH) was obtained, and then calcined at 500 °C for 4 h to obtain the metal-based support (γ-Al 2 o 3 / Al), metal-based carrier γ-Al 2 o 3 The XRD pattern of / Al is shown in image 3 .

[0049] (2) Chlorine-doped modification: the metal-based carrier is immersed in 1.0mol / L a...

Embodiment 2

[0054] Same as Example 1, the difference is that the soaking time in step (2) is 1h.

Embodiment 3

[0056] Same as Example 1, the difference is that the soaking time in step (2) is 3h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com